Drilling machine for large-diameter down hole hammer

A down-the-hole hammer and large-diameter technology, used in drilling equipment, earth-moving drilling, driving devices for drilling in wellbore, etc., to ensure long-life operation, improve overall construction efficiency, and reduce environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

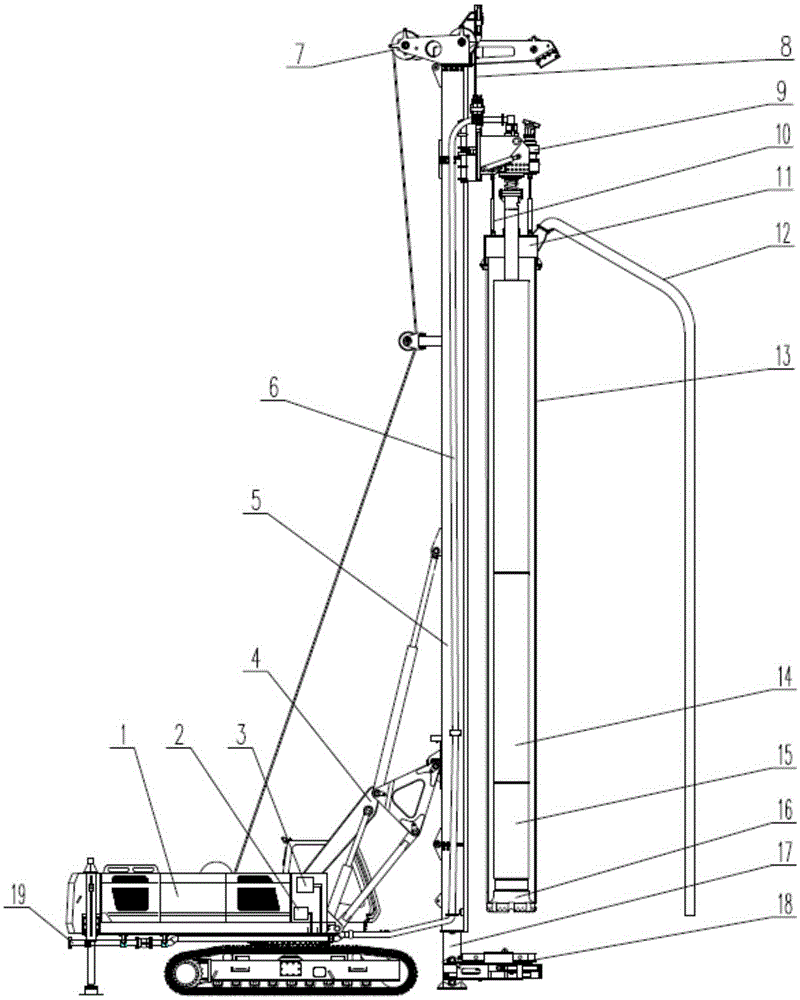

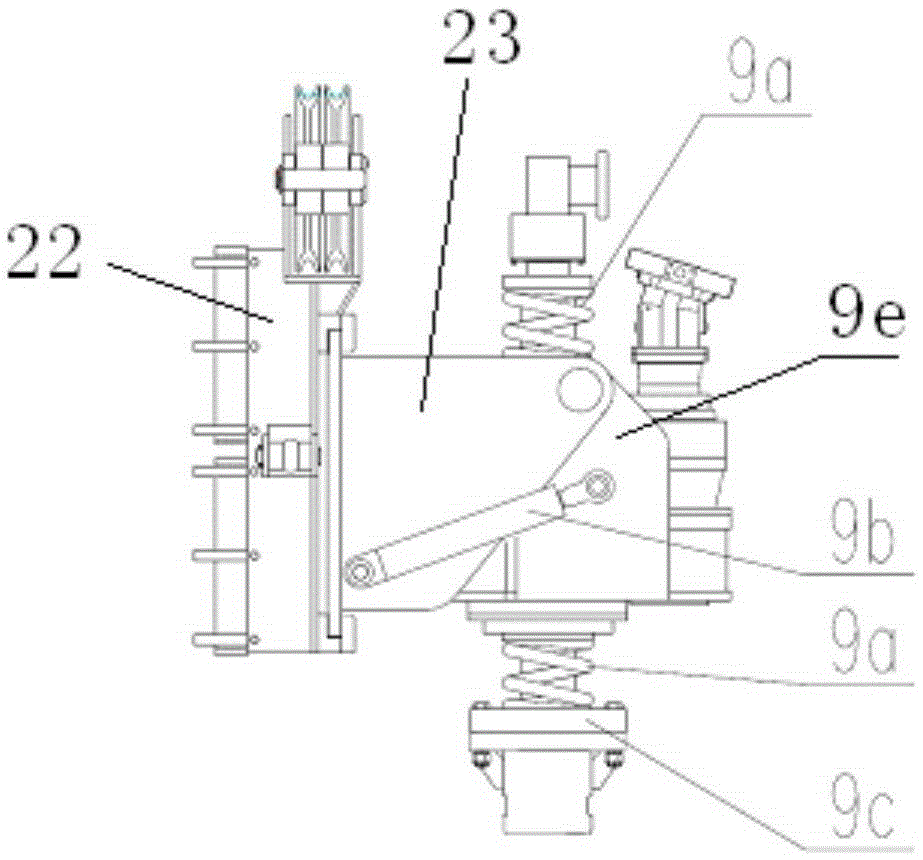

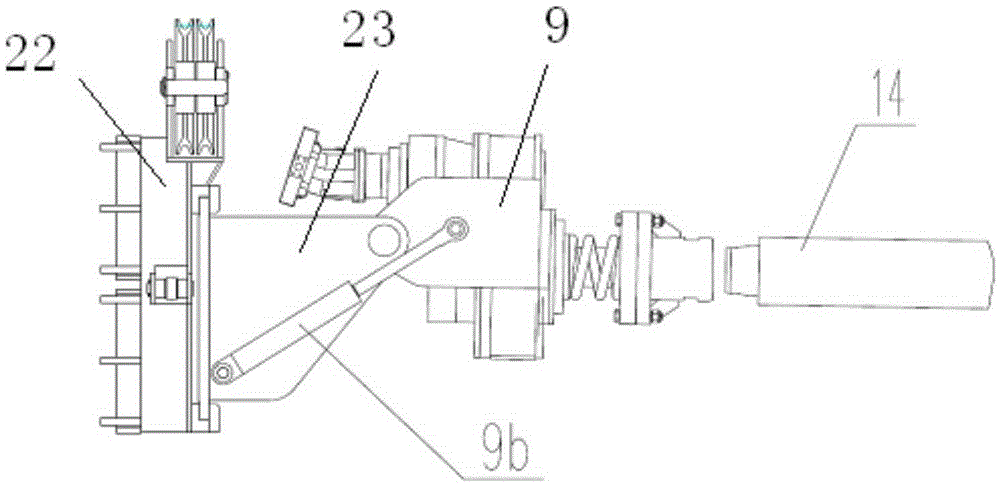

[0030] see figure 1 The large-diameter down-the-hole hammer drilling rig includes chassis 1, water channel 2, oil channel 3, luffing mechanism 4, mast 5, air intake channel 6, goose head 7, main coil wire rope 8, power head 9, lifting cylinder 10, Slag discharge head 11, slag discharge pipe 12, casing 13, drill pipe 14, down-the-hole hammer 15, drill bit 16, telescopic front outrigger 17, pile clamp 18 and air inlet port 19. The water passage 2 and the oil passage 3 are all connected in parallel on the air intake passage 6, and the operation of the drilling rig can control the opening and closing of each passage, and adjust the size of the opening passage. The luffing mechanism 4 is operated to control the lifting and down-mast of the mast 5, which facilitates the transportation and alignment of the machine. The main winch arranged on the chassis 1 slides up and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com