A kind of preparation method of polyacrylonitrile-based high-strength conductive fiber

A polyacrylonitrile fiber, polyacrylonitrile-based technology, applied in the direction of fiber type, fiber treatment, fiber chemical characteristics, etc., can solve the problem of unsatisfactory conductivity of conductive PAN fiber, poor strength of conductive PAN fiber, and shedding of conductive layer And other problems, to achieve the effect of good spinnability, high strength, good conductivity and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

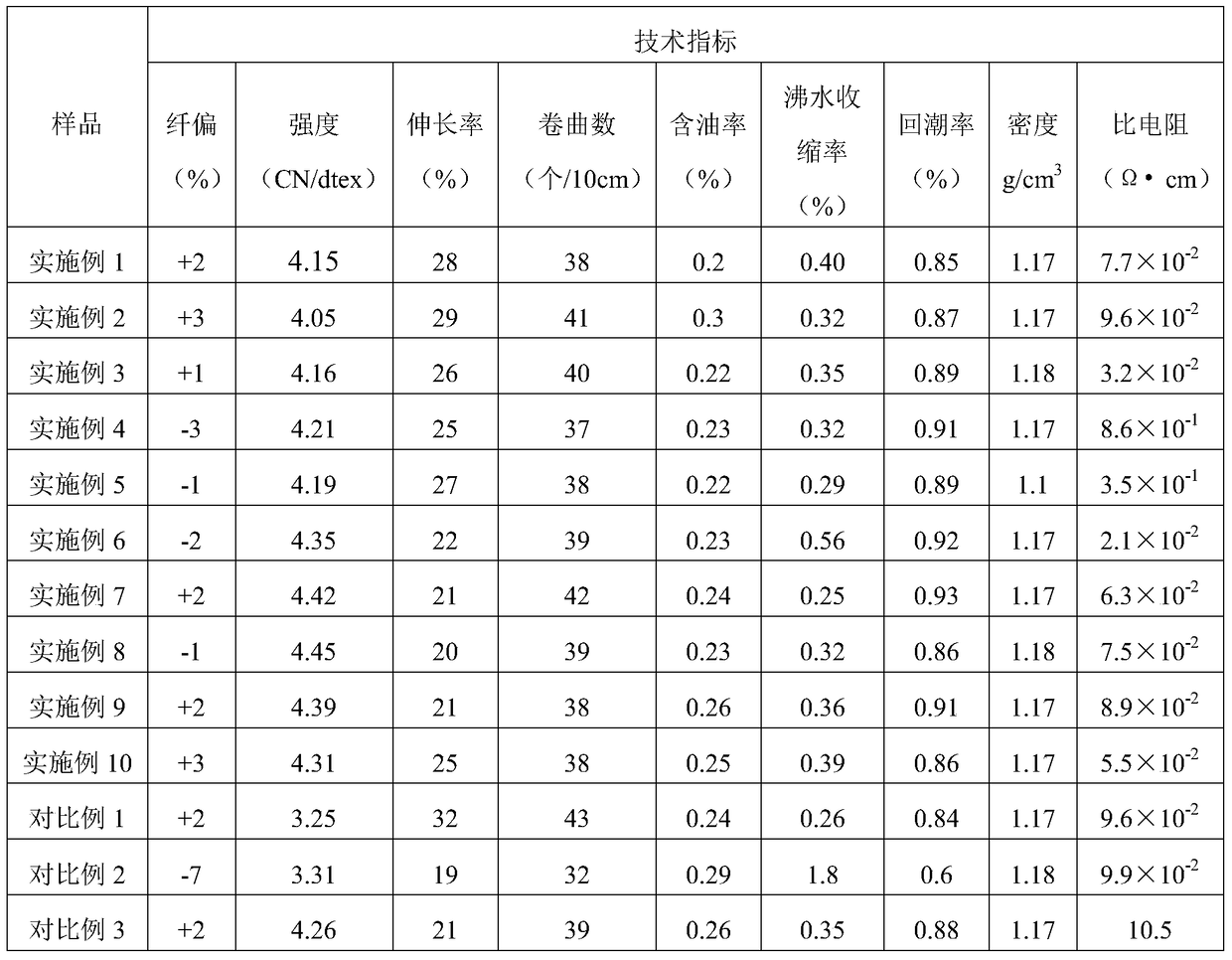

Examples

Embodiment 1

[0049] 1) Mix acrylonitrile and vinyl acetate at a mass ratio of 93:7, and then produce polyacrylonitrile fibers through dimethylacetamide wet two-step spinning production technology after aqueous phase suspension polymerization;

[0050] 2) Place polyacrylonitrile fibers in an environment of 150-170°C for high-temperature drafting to further increase the degree of fiber molecular orientation, and the drafting ratio is 1.5-2 times;

[0051] 3) Place the polyacrylonitrile fiber after high-power drafting in saturated low-pressure steam of 150-200Kpa (absolute pressure) for 38 minutes to improve the dimensional stability of the fiber;

[0052] 4) Put the polyacrylonitrile fiber in a sodium hydroxide solution with a concentration of 0.5%, remove the oil agent and impurities on the surface of the fiber, then repeatedly wash and dry with desalted water;

[0053] 5) Under a certain pressure, put the cleaned polyacrylonitrile fibers in an aqueous solution with a concentration of 2% co...

Embodiment 2

[0059] 1) Mix acrylonitrile and vinyl acetate at a mass ratio of 94:6, and then produce polyacrylonitrile fibers through dimethylacetamide wet two-step spinning production technology after aqueous phase suspension polymerization;

[0060] 2) Place polyacrylonitrile fibers in an environment of 160-170°C for high-temperature drafting to further increase the degree of fiber molecular orientation, and the drafting ratio is 1.5-2 times;

[0061] 3) Place the high-stretched polyacrylonitrile fiber in saturated low-pressure steam of 150-200Kpa (absolute pressure) for 35 minutes to improve the dimensional stability of the fiber;

[0062] 4) Put the polyacrylonitrile fibers in a sodium hydroxide solution with a concentration of 1%, remove the oil agent and impurities on the surface of the fibers, then repeatedly wash and dry with desalted water;

[0063] 5) Under a certain pressure, put the cleaned polyacrylonitrile fibers into an aqueous solution with a concentration of 4% copper sulf...

Embodiment 3

[0069] 1) Mix acrylonitrile and vinyl acetate at a mass ratio of 92:8, and then produce polyacrylonitrile fibers through dimethylacetamide wet two-step spinning production technology after aqueous phase suspension polymerization;

[0070] 2) Place polyacrylonitrile fibers in an environment of 160-170°C for high-temperature drafting to further increase the degree of fiber molecular orientation, and the drafting ratio is 1.5-2 times;

[0071] 3) Place the polyacrylonitrile fibers after high-power drafting in saturated low-pressure steam of 150-200Kpa (absolute pressure) for 40 minutes to improve the dimensional stability of the fibers;

[0072] 4) Put the polyacrylonitrile fiber in a sodium hydroxide solution with a concentration of 0.8%, remove the oil agent and impurities on the surface of the fiber, then repeatedly wash and dry with desalted water;

[0073] 5) Under a certain pressure, put the cleaned polyacrylonitrile fibers in an aqueous solution with a concentration of 3% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com