A polygeneration system and method guided by coal pyrolysis

A technology of polygeneration and coal pyrolysis, applied in the field of coal chemical industry, can solve the problems of inability to enter the stage of industrial application, difficulty in scaling up equipment specifications, and low quality of pyrolysis gas, so as to improve energy conversion efficiency, reduce emissions and pollution, The effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

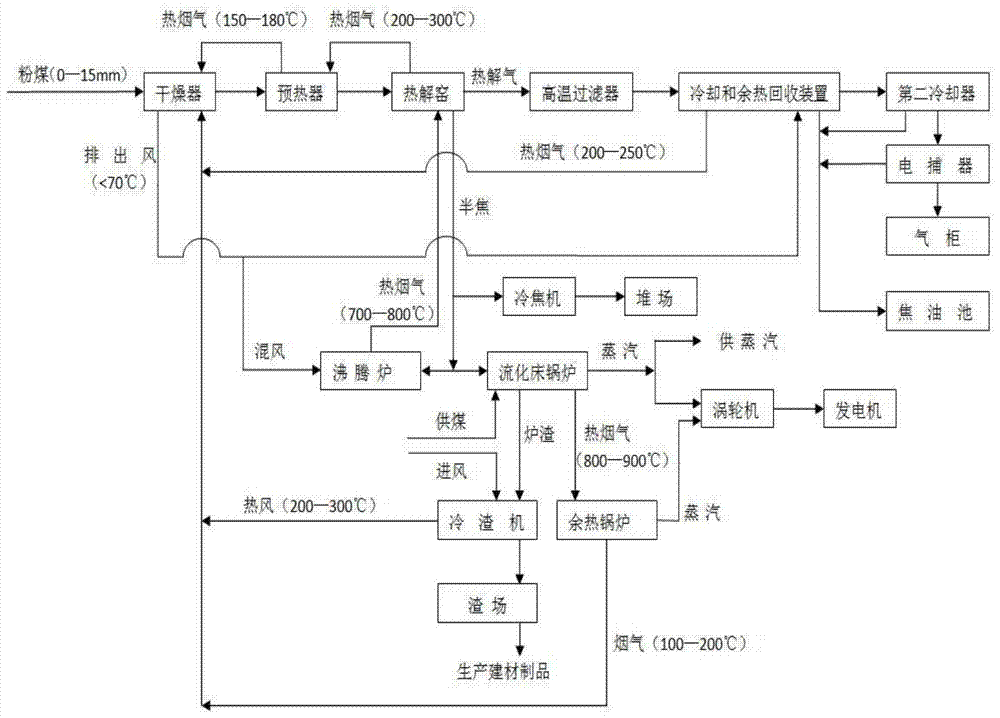

[0033] combine figure 1 , the working process and specific implementation methods of the present invention will be further described below.

[0034] The invention includes two units altogether, that is, a coal pyrolysis unit using a multi-heating tube rotary pyrolysis kiln and a combustion power generation unit of a circulating fluidized bed boiler. The system consists of dryer, preheater, pyrolysis kiln, high temperature gas filter, pyrolysis gas cooling and waste heat recovery device, second cooler, electric tar collector, cold coke machine, circulating fluidized bed boiler, waste heat recovery boiler , steam turbine, generator, slag cooler, fluidized fluidized furnace and other devices.

[0035] After screening and removing impurities, the pulverized coal with a particle size of 0-15mm and a moisture content of less than 20% first enters the dryer for drying, and the moisture is reduced to less than 5%, and then enters the back-end preheater to preheat to 200 ~250°C, ente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com