Ultraviolet light-cured coating and preparation method thereof

A technology of curing paint and ultraviolet light, which is applied in the field of paint, can solve the problems of yellowing of paint film, reducing the durability of buildings, pulverization, etc., and achieves the effects of good environmental performance, easy industrial production, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

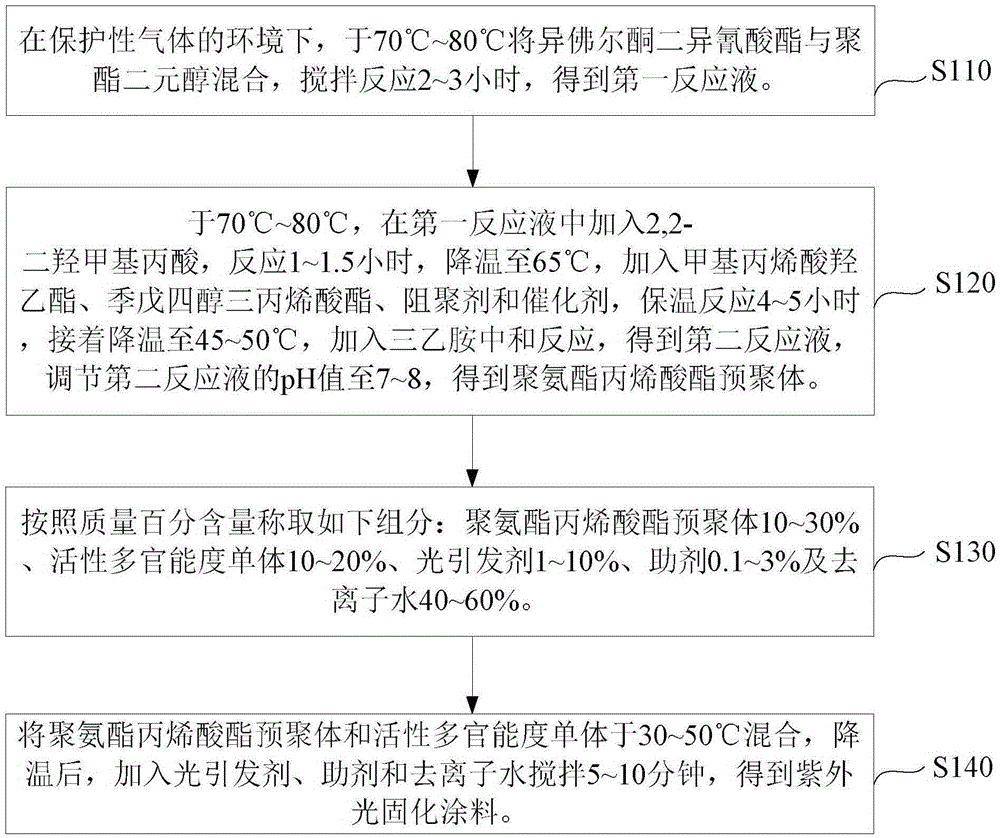

[0023] Such as figure 1 Shown, the preparation method of the ultraviolet curing coating of one embodiment, comprises the steps:

[0024] Step S110 : under a protective gas environment, mix isophorone diisocyanate and polyester diol at 70° C. to 80° C., stir and react for 2 to 3 hours to obtain a first reaction liquid.

[0025] Wherein, the protective gas can be nitrogen or inert gas.

[0026] Step S120: Add 2,2-dimethylolpropionic acid to the first reaction liquid at 70°C-80°C, react for 1-1.5 hours, cool down to 65°C, add hydroxyethyl methacrylate and pentaerythritol triacrylic acid Esters, polymerization inhibitors and catalysts, keep warm for 4-5 hours, then lower the temperature to 45-50°C, add triethylamine to neutralize the reaction to obtain the second reaction solution, adjust the pH value of the second reaction solution to 7-8, A urethane acrylate prepolymer was obtained.

[0027] in,

[0028] The molar weight of described isophorone diisocyanate is equal to descr...

Embodiment 1

[0043] The preparation process of the UV-curable coating of the present embodiment is as follows:

[0044] 1. Under the condition of nitrogen protection, add isophorone diisocyanate into a four-necked round reaction flask with a thermometer, a condenser, and a stirring rod, and place it at 70°C for 10 minutes to preheat the polyester Dihydric alcohol was added dropwise into the four-necked reaction flask, stirred and reacted for 2 hours to obtain the first reaction liquid.

[0045]2. At 70°C, add 2,2-dimethylolpropionic acid to the first reaction liquid, react for 1.5 hours, cool down to 65°C, add hydroxyethyl methacrylate, pentaerythritol triacrylate, and polymerization inhibitor React with the catalyst for 4 hours, then lower the temperature to 50°C, add triethylamine to neutralize the reaction to obtain a second reaction liquid, adjust the pH value of the second reaction liquid to 7, and obtain a polyurethane acrylate prepolymer. Wherein, the molar weight of the isophorone...

Embodiment 2

[0049] The preparation process of the UV-curable coating of the present embodiment is as follows:

[0050] 1. Under the condition of nitrogen protection, add isophorone diisocyanate into a four-necked round reaction flask with a thermometer, a condenser tube and a stirring rod, and place it at 80 ° C for 10 minutes to preheat the polyester Dihydric alcohol was added dropwise into the four-necked reaction flask, stirred and reacted for 2 hours to obtain the first reaction liquid.

[0051] 2. At 80°C, add 2,2-dimethylolpropionic acid to the first reaction liquid, react for 1.5 hours, cool down to 65°C, add hydroxyethyl methacrylate, pentaerythritol triacrylate, polymerization inhibitor and Catalyst, heat preservation reaction for 5 hours, then lower the temperature to 50° C., add triethylamine for neutralization reaction to obtain a second reaction liquid, adjust the pH value of the second reaction liquid to 8, and obtain a polyurethane acrylate prepolymer. Wherein, the molar w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com