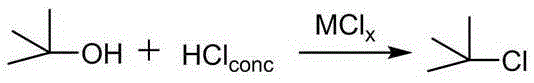

Preparation method of tert-butyl chloride

A technology of tert-butyl chloride and tert-butanol, which is applied in the field of preparation of tert-butyl chloride, can solve the problems of low reaction yield, high equipment investment, complex production process, etc., and achieves improved yield, less equipment investment, The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 200 grams of tert-butanol into a 1000ml reaction flask, stir, then add 400 grams of concentrated hydrochloric acid, 200 g of sodium chloride, control the temperature in a water bath at 50°C, stir and react for 5 hours, let stand for the first layering, and separate the water layer. After neutralizing the organic layer obtained by the first layering with 10 g of sodium hydroxide, let it stand for the second layering, separate the water layer, add 40 g of sodium sulfate to the organic layer obtained for the second layering, and dry it. After 1h, the desiccant was filtered off and distilled to obtain 240g of tert-butyl chloride. Yield 96%, GC99.7%.

Embodiment 2

[0026] Add 200 grams of tert-butanol into a 1000ml reaction flask, stir, then add 400 grams of concentrated sulfuric acid, 200 g of sodium chloride, control the temperature in a water bath at 60°C, stir and react for 7 hours, let stand for the first layering, and separate the water layer. After the organic layer obtained by the first layering was neutralized with 10 g of sodium carbonate, it was left to stand for the second layering, and the water layer was separated, and the organic layer obtained by the second layering was added with 50 g of sodium sulfate to dry. After drying for 1 h, the desiccant was filtered off and distilled to obtain 237 g of tert-butyl chloride. Yield 95%, GC99.8%.

Embodiment 3

[0028] Add 200 grams of tert-butanol into a 1000ml reaction flask, stir, then add 350 grams of glacial acetic acid, 200 g of calcium chloride, control the temperature in a water bath at 55°C, stir and react for 8 hours, let stand for the first layering, and separate the water layer. After the organic layer obtained by the first layering was neutralized with 10 g of sodium hydroxide, it was left to stand for the second layering, and the water layer was separated, and the organic layer obtained by the second layering was added with 40 g of calcium chloride to dry. After drying for 1 h, the desiccant was filtered off and distilled to obtain 240.3 g of tert-butyl chloride. Yield 96.2%, GC99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com