Method for zero emission production of gold mine tailings

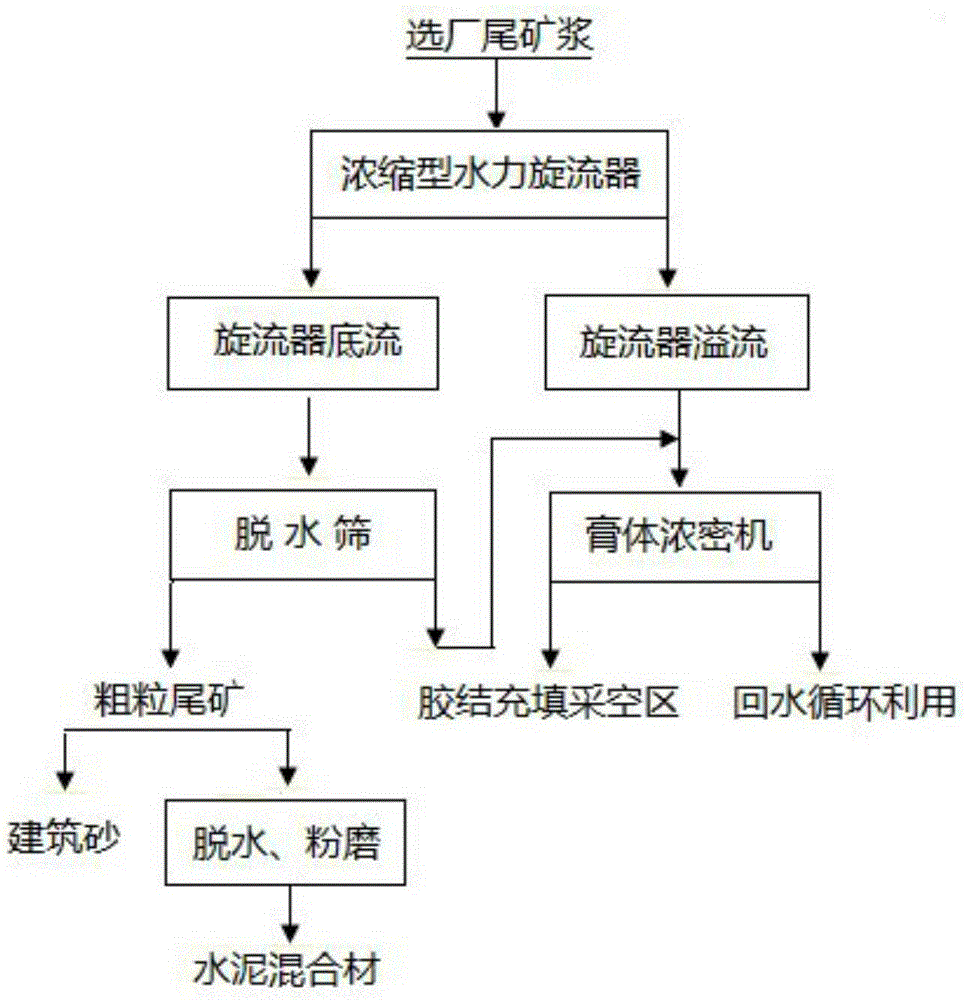

A production process, technology of gold mine tailings, applied in mining equipment, sustainable waste treatment, solid waste management, etc., can solve the problems of vegetation destruction, capital consumption, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A gold mine processes 1000t of raw ore per day. Using this production process, the coarse-grained tailings, which account for 40% of the total tailings, are used to prepare cement admixtures, and the fine-grained tailings, which account for 60% of the total tailings, are concentrated by a high-efficiency thickener. The goaf is filled with cementation, and the overflowed water from the thickener is reused in the dressing plant to achieve zero-emission production of tailings.

Embodiment 2

[0026] A gold mine has a daily processing capacity of 1200t of raw ore. Using this production process, the coarse-grained tailings, which account for 25% of the total tailings, are used to prepare construction sand, and the coarse-grained tailings, which account for 20% of the total tailings, are used to prepare cement admixtures. In addition, the fine-grained tailings, which account for 55% of the total tailings, are concentrated by a high-efficiency thickener and then cemented to fill the goaf.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com