Apparatus and method for preparing high specific surface area active carbon through alkali activation process

A high specific surface area, activated carbon technology, applied in the field of chemical activation, can solve the problems of uneven mixing, low production efficiency, complex structure of stirring device, etc., achieve continuous production, improve product quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

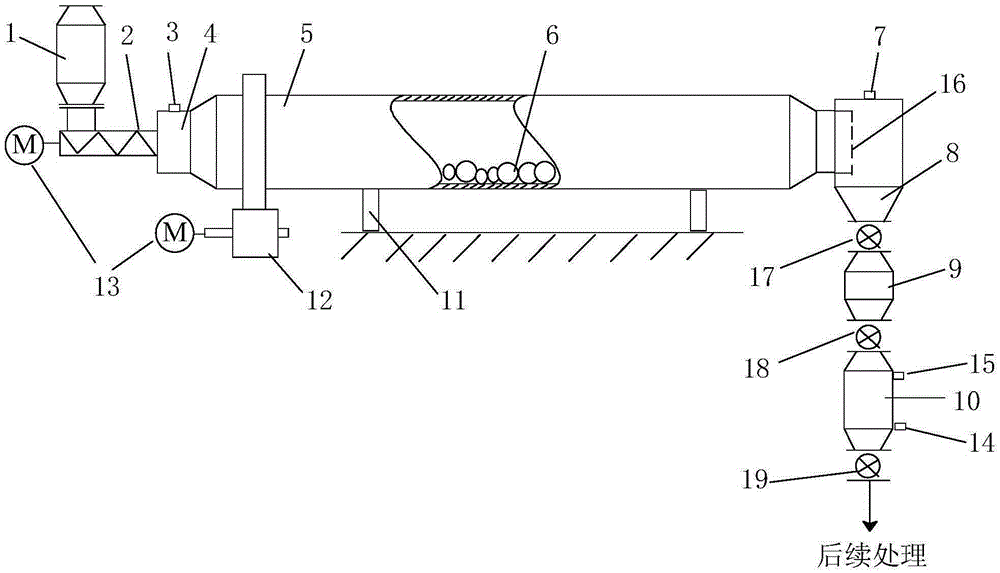

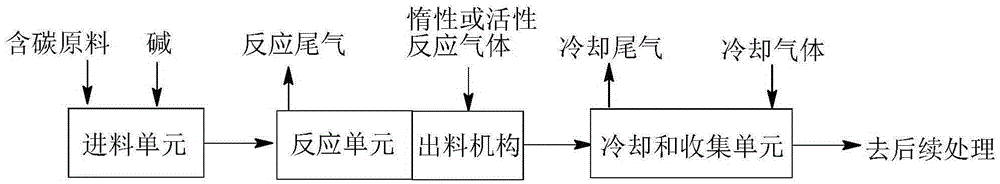

Method used

Image

Examples

Embodiment 1

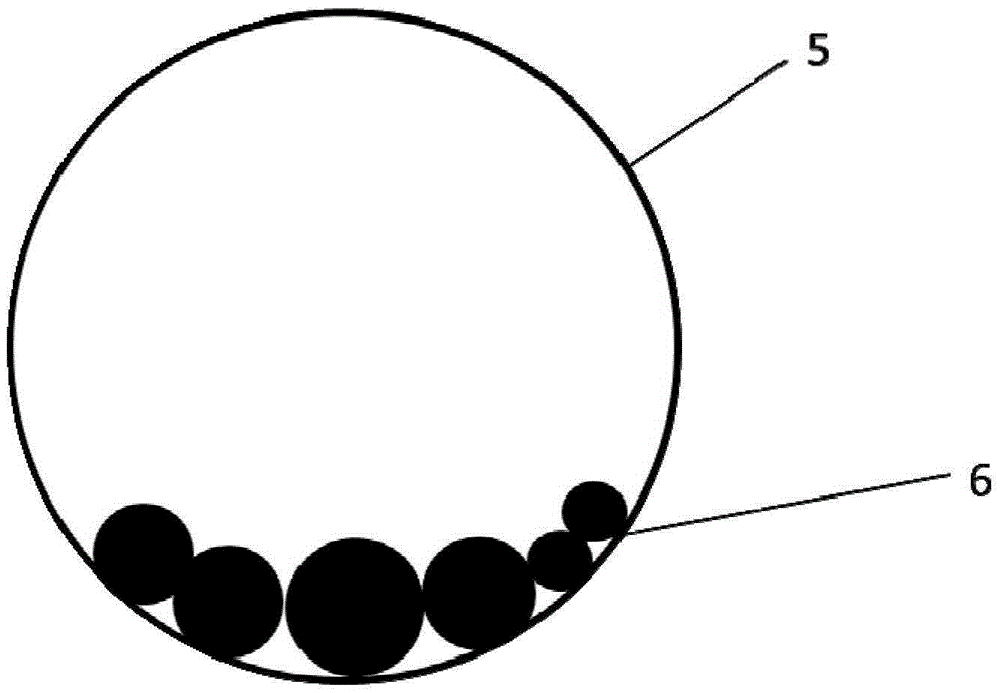

[0047] The pre-activation experiment of raw material carbon and alkali is carried out in the described device. The main technical parameters of the experiment are as follows: the raw materials are petroleum coke and KOH, the particle size of petroleum coke is less than 150 μm, and the mass ratio of alkali coke is 2:1; 20mm, the effective length of the furnace body is 900mm; the opening of the feeding motor is 50%, the rotation speed is 2.7r / min, and the feed volume of the mixture is 10g / min; . 2 . The products with different numbers of balls are labeled as 1#, 2#, 3#, 4# respectively, and the status of the products is shown in Table 1.

[0048] Table 1 The discharge state of the prepared product under different ball quantities

[0049]

Embodiment 2

[0051] The proportion of the total volume of the balls placed in the furnace body is 0.2, the speed of the furnace body is 10r / min, 20r / min, and 30r / min, and the other conditions are the same as in Example 1. The products under different furnace body speeds are respectively labeled 1 #, 2#, 3#, the discharge state is shown in Table 2.

[0052] Table 2 The discharge state of the prepared product under different furnace speeds

[0053]

Embodiment 3

[0055] The proportion of the total volume of the balls placed in the furnace is 0.2, the preactivation heating temperature is 450°C, 500°C, and 550°C respectively, and other conditions are the same as in Example 1. After the cooled material is taken out, it is washed with 1mol / L hydrochloric acid, and then used Washing with deionized water until the pH of the filtrate reaches 6-7, putting the filtered solid product into an oven at 105-110°C and drying it to constant weight to obtain the final product. The low-temperature nitrogen adsorption experiment was carried out on the obtained final product, and the products under different heating temperatures were respectively labeled as 1#, 2#, and 3# to obtain the specific surface area and pore volume of the product as shown in Table 2.

[0056] Table 3 The specific surface area and pore volume of the preactivated product under different heating temperatures

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com