Chemical vapor deposition equipment and method for preparing graphene film

A chemical vapor deposition and graphene film technology, applied in the field of chemical vapor deposition equipment and the preparation of graphene films by using the equipment, can solve the problems of increasing equipment costs, potential safety hazards, etc., and achieve increased safety, cost savings in preparation and safety management Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

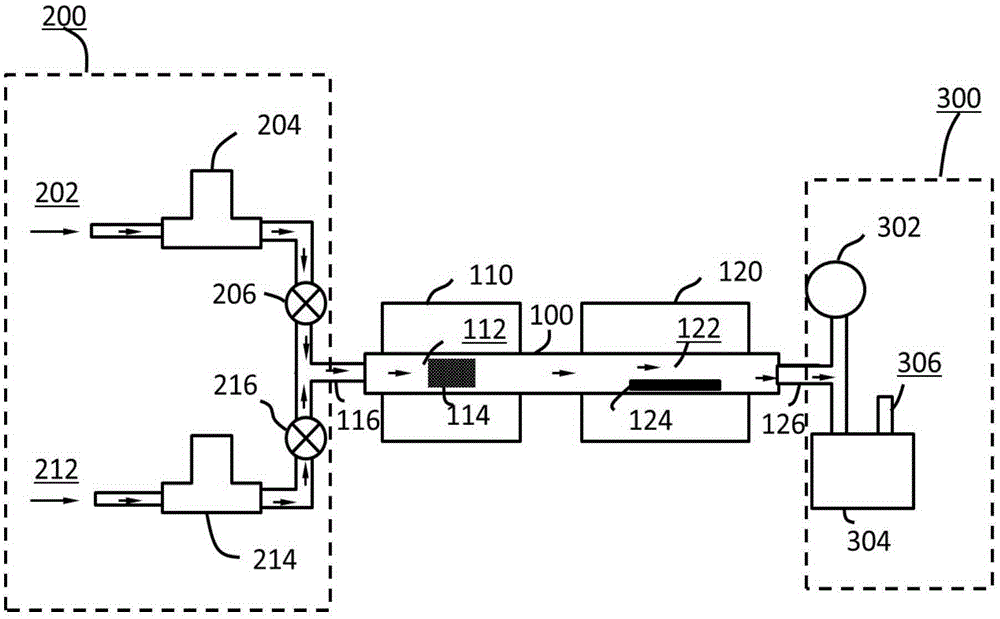

[0020] see figure 1 . The chemical vapor deposition equipment for preparing graphene film includes: gas conversion reaction chamber 112 and heating device 110 for heating gas conversion reaction chamber 112, graphene film growth reaction chamber 122 and for heating graphene film growth reaction chamber The heating device 120 , the intake air management system 200 , the vacuum system 300 and the graphite rod 114 placed in the gas conversion reaction chamber 112 .

[0021] One end of the gas conversion reaction chamber 112 is sealed and connected to the intake management system 200 through the air inlet 116, and the other end of the graphene film growth reaction chamber 122 is sealed and connected to the vacuum system 300 through the gas outlet port 126. , the gas conversion reaction chamber 112 and the graphene film growth reaction chamber 122 are directly communicated by using a quartz tube 100 . The diameter of the quartz tube 100 is 5 cm to 50 cm.

[0022] The graphite ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com