Large-scale gantry equipment has a level beam crawling lifting device

A lifting device, gantry technology, applied in the direction of lifting equipment braking device, hoisting device, transportation and packaging, etc., can solve the problems of low degree of automation, the lifting device cannot be overloaded, and the safety is not good, and achieves work reliability. Improve, ensure stability, and ensure the effect of smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

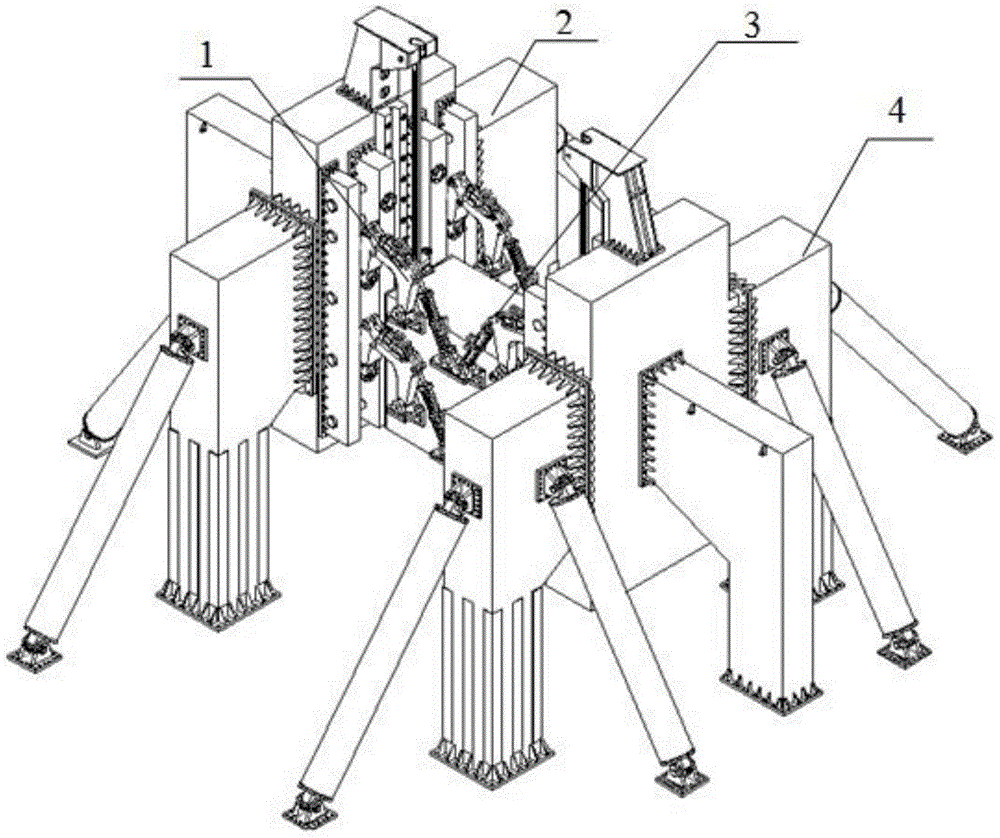

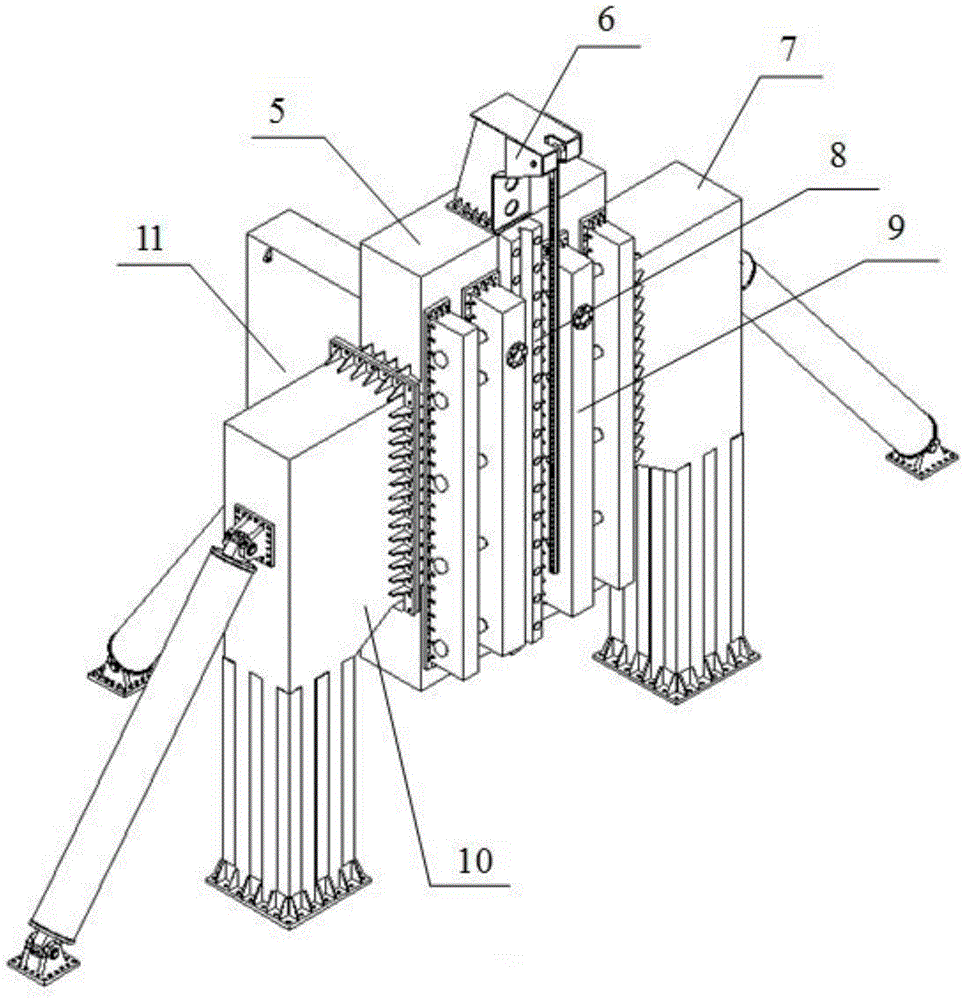

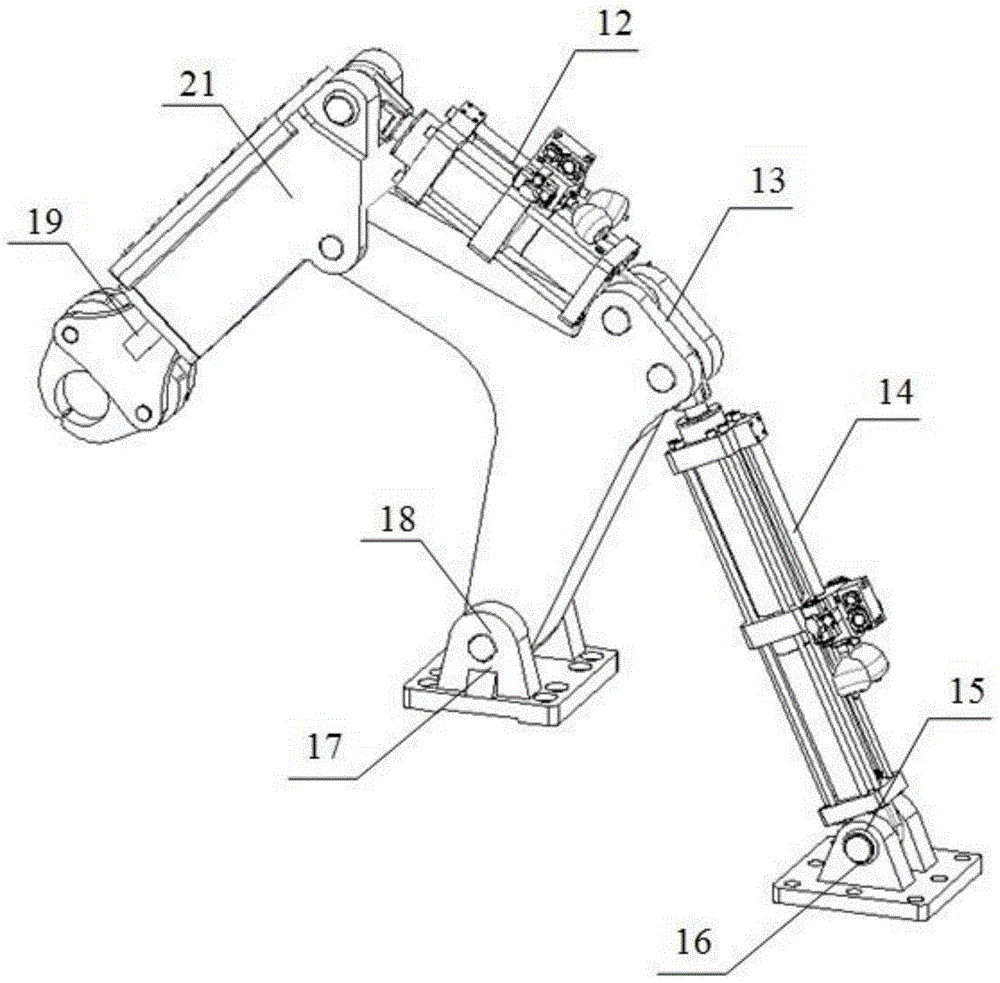

[0061] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

[0062] The purpose of the present invention is to provide a large-scale gantry equipment stepped beam crawling lifting device, which is used to complete the stepped lifting of heavy objects, mainly to meet the working requirements of the stepped beam above 30T. The driving of the overall lifting device comes from the oil supply of the hydraulic station. The control mechanism of the hydraulic station completes the control of the oil supply volume and oil supply speed of each hydraulic actuator, so that the hydraulic actuator can complete the corresponding action. In order to be more accurate To complete the lifting movement, each actuator is equipped with a displacement sensor, a force sensor, and a servo valve body to ensure sufficient displacement of the piston rod of the actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com