Production process of electric rice cooker

A production process and rice cooker technology, which is applied to household containers, home utensils, table utensils, etc., can solve the problems of poor work efficiency and low pass rate, and achieve the effect of solving low work efficiency, high work efficiency and broad prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

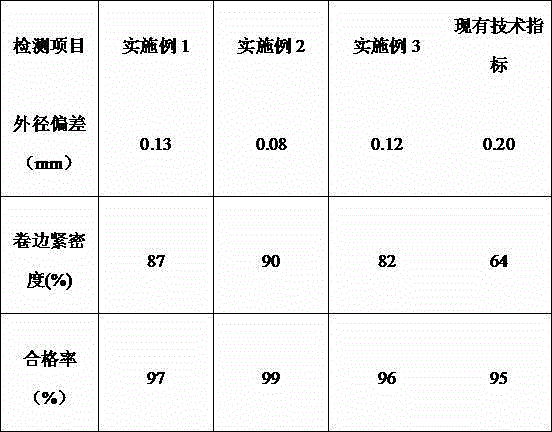

Examples

Embodiment 1

[0029] A kind of electric rice cooker production technology, comprises the steps:

[0030] (1) Steel plate cutting

[0031] Use a cutting machine to cut the rust-free steel plate into a strip shape, and then remove the edge material from the strip-shaped rust-free steel plate after cutting. The speed of the cutting machine is 40mm / s, and the power of the cutting machine is 2000w;

[0032] (2) Stretch

[0033] The strip-shaped rust-free steel plate is transported to the workpiece table through the feeding rack, and then it is sucked by the manipulator and sent to the die of the stretching machine tool, and then the strip-shaped rust-free steel plate is first pressed by the pressing plate on the stretching machine tool, and then The punch of the stretching machine tool enters the die and stretches the strip-shaped rust-free steel plate. The number of stretches is 4 times. Lubricating oil is added during the stretching process. The amount of lubricating oil The composition and ...

Embodiment 2

[0047] A kind of electric rice cooker production technology, comprises the steps:

[0048] (1) Steel plate cutting

[0049] Use a cutting machine to cut the rust-free steel plate into a strip shape, and then remove the edge material from the strip-shaped rust-free steel plate after cutting. The speed of the cutting machine is 50mm / s, and the power of the cutting machine is 2500w;

[0050] (2) Stretch

[0051] The strip-shaped rust-free steel plate is transported to the workpiece table through the feeding rack, and then it is sucked by the manipulator and sent to the die of the stretching machine tool, and then the strip-shaped rust-free steel plate is first pressed by the pressing plate on the stretching machine tool, and then The punch of the stretching machine tool enters the die and stretches the strip-shaped rust-free steel plate. The number of stretches is 5 times. Lubricating oil is added during the stretching process. The amount of lubricating oil The composition and ...

Embodiment 3

[0065] A kind of electric rice cooker production technology, comprises the steps:

[0066] (1) Steel plate cutting

[0067] Use a cutting machine to cut the rust-free steel plate into strips, and after cutting, remove the edge material from the strip-shaped rust-free steel plate. The speed of the cutting machine is 60mm / s, and the power of the cutting machine is 3000w;

[0068] (2) Stretch

[0069] The strip-shaped rust-free steel plate is transported to the workpiece table through the feeding rack, and then it is sucked by the manipulator and sent to the die of the stretching machine tool, and then the strip-shaped rust-free steel plate is first pressed by the pressing plate on the stretching machine tool, and then The punch of the stretching machine tool enters the die and stretches the strip-shaped rust-free steel plate. The number of stretches is 6 times. Lubricating treatment is carried out by adding lubricating oil during the stretching process. The composition and pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com