A Drilling Device for Release of Fission Gas from Heavy Water Reactor Fuel Elements

A fuel element and fission gas technology, which is applied in boring/drilling, drilling/drilling equipment, and components of boring machines/drilling machines, etc., can solve the problem that technical parameters are difficult to control, equipment maintenance is difficult, and mechanical piercing is difficult to popularize and use. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

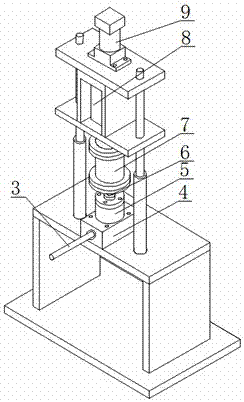

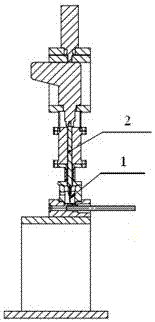

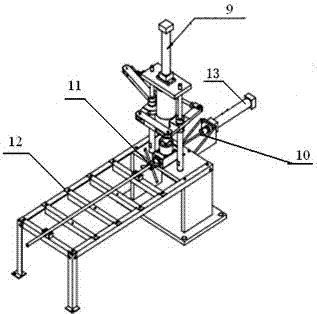

[0032] Such as figure 1 , figure 2 A drilling device for the release of fission gas from heavy water reactor fuel elements is shown, including a frame, on which a sealing seat A4 is arranged, and a hole A for installing a heavy water reactor fuel element 3 is arranged in the sealing seat A4, and the sealing The seat A4 is also provided with a seal for sealing the gap between the heavy water reactor fuel element 3 and the hole A of the seal seat A4, the seal seat A4 is connected with a gas collection seat 5, and the gas collection seat 5 has a structure that runs through the gas collection seat 5 and is perpendicular to the gas collection seat 5. The through hole B of the hole A, and the hole C at one end of the communicating hole A and the through hole B are arranged on the sealing seat A4. The gas collection seat 5 is connected to the sealing seat B7 through the axially telescopic pipe fitting 6, and one end of the pipe fitting 6 communicates with the through hole At the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com