A kind of alkali solution cleaning in the spray desulfurization tower efficiently removes SO 3 craft

A technology of lye cleaning and desulfurization tower, which is applied in the direction of gas treatment, dispersed particle separation, membrane technology, etc., can solve the problems of low dust removal efficiency of high specific resistance dust, inability to apply high sulfur coal power plants, weakening electrostatic adhesion of dust, etc. , to achieve good removal effect, small amount of transformation, small investment in process transformation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

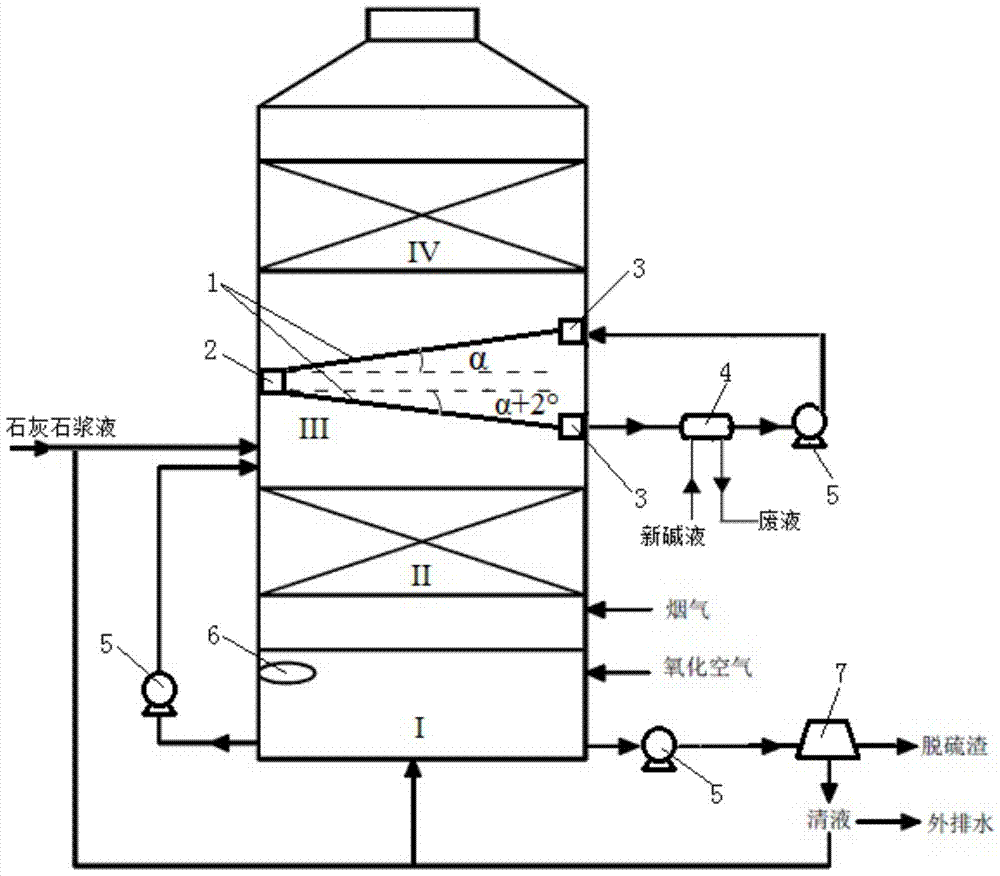

[0030] Wet flue gas desulfurization system mainly includes flue gas system, SO 2 Absorption system, limestone slurry preparation system, gypsum dehydration storage system, wastewater treatment system, utility system, thermal control system and electrical system, of which SO 2 Absorption is the most critical process in wet flue gas desulfurization technology, so the desulfurization tower is the core part of the system.

[0031] Such as figure 1 As shown, for a general spray desulfurization tower, the flue gas from the flue gas-flue gas reheater enters the tower from the side of the desulfurization tower, and the flue gas inlet is between the limestone slurry circulation zone I and the deSO 2 The po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com