Preparation method for ultra-thin Li4Ti5O12 nanosheet assisted by surfactant, and use method for ultra-thin Li4Ti5O12 nanosheet in lithium battery and sodium battery

A surfactant and nanosheet technology, applied in the field of electrochemical power supply and energy storage, can solve the problems of product impurity, complicated process, easy to pollute the environment, etc., and achieve the effect of single crystal phase structure, simple process and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

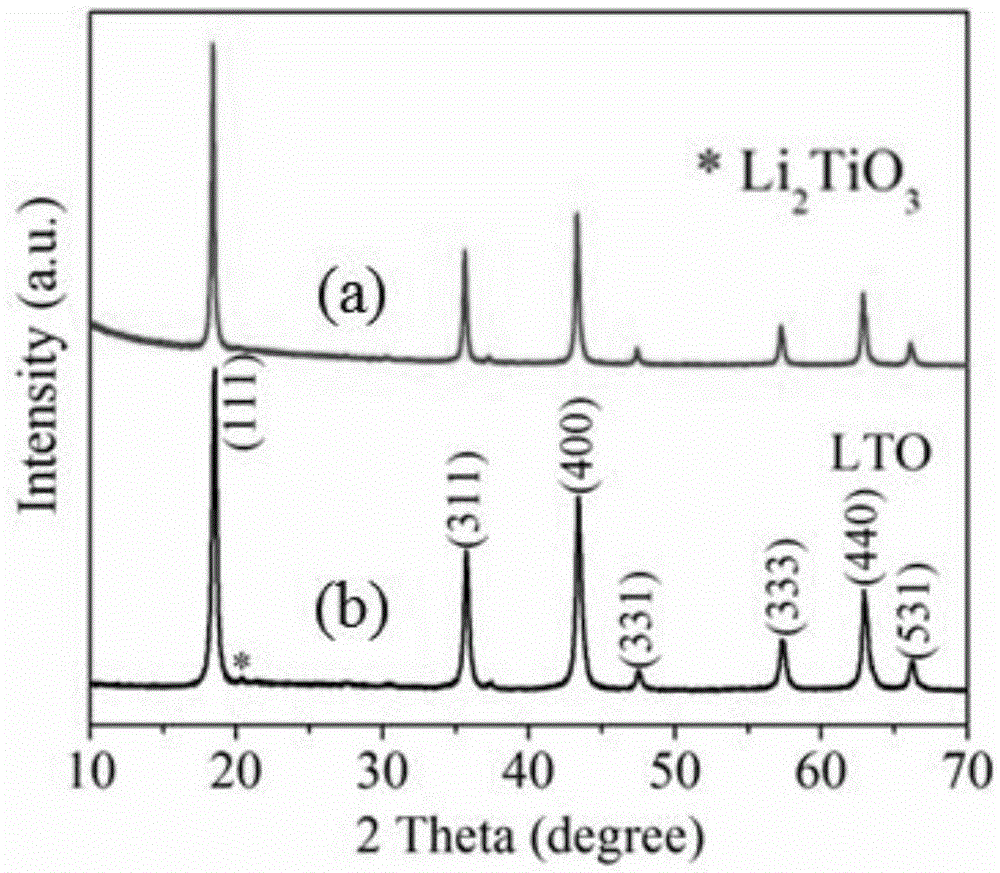

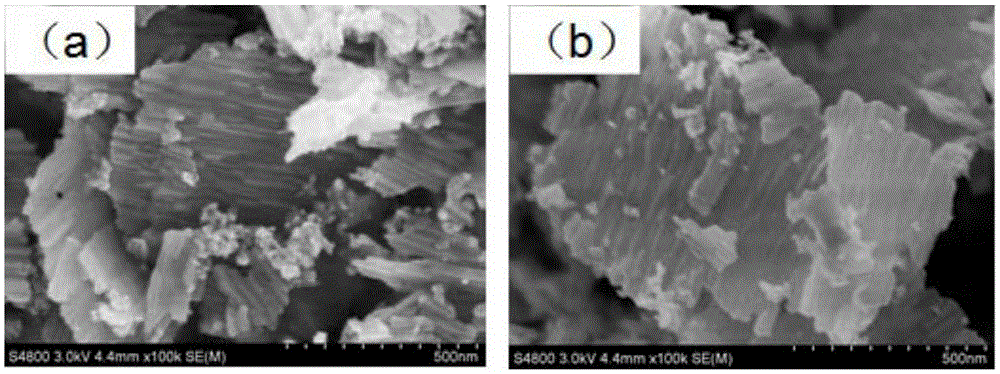

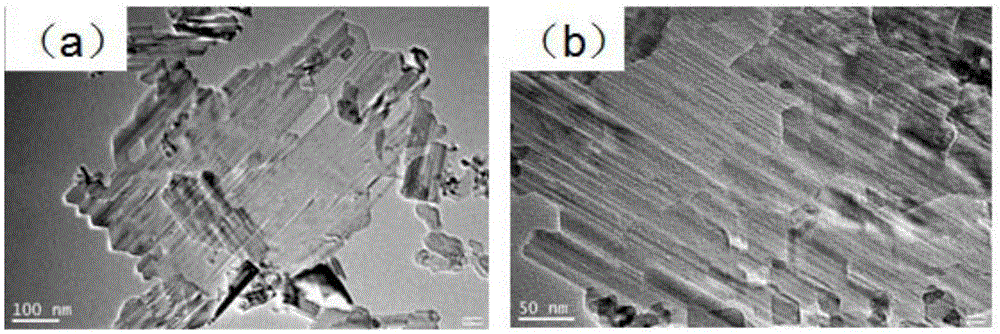

[0028] Add 0.3156g of P123 to 10ml of absolute ethanol, stir and dissolve in a water bath at 60°C, and configure solution A; add 3.8238g of tetrabutyl titanate to 20ml of In water and ethanol, stir for 10 minutes to configure solution B, then add solution A dropwise to solution B, stir continuously for 5 hours, and configure solution C; dissolve 0.3864g lithium hydroxide monohydrate in 5ml deionized water , configured into solution D, and then added solution D dropwise to solution C under stirring, and continuously stirred for 30 minutes to obtain suspension E; move suspension E to a polytetrafluoroethylene-lined stainless steel reactor, Hydrothermal reaction was carried out at 160°C for 12 hours. After the reaction, cool to room temperature, and then dry at 80°C for 24 hours to obtain a lithium titanate precursor, and finally heat-treat the obtained precursor in a muffle furnace at 600°C for 3 hours to obtain an ultra-thin Li 4 Ti 5 o 12 nanosheet material. See figure 1 ...

Embodiment 2

[0032] Add 0.1583g of P123 to 10ml of absolute ethanol, stir and dissolve in a water bath at 50°C, and configure solution A; add 3.8247g of tetrabutyl titanate to 20ml of In water and ethanol, stir for 20 minutes to configure solution B, then add solution A dropwise to solution B, stir continuously for 4 hours, and configure solution C; dissolve 0.39123g lithium hydroxide monohydrate in 5ml deionized water , configured into solution D, and then added solution D dropwise to solution C under stirring, and continuously stirred for 40 minutes to obtain suspension E; move suspension E to a polytetrafluoroethylene-lined stainless steel reactor, Hydrothermal reaction was carried out at 150°C for 24 hours. After the reaction, cool to room temperature, and then dry at 100°C for 20 hours to obtain a lithium titanate precursor. Finally, the obtained precursor is ground and heat-treated in a muffle furnace at 700°C for 2 hours to obtain an ultra-thin Li 4 Ti 5 o 12 nanosheet material. ...

Embodiment 3

[0034] Add 0.3142g of F127 to 10ml of absolute ethanol, stir and dissolve in a water bath at 60°C, and configure solution A; add 3.8247g of tetrabutyl titanate to 20ml of In water and ethanol, stir for 20 minutes to configure solution B, then add solution A dropwise to solution B, stir continuously for 4 hours, and configure solution C; dissolve 0.3858g lithium hydroxide monohydrate in 5ml deionized water , configured into solution D, and then added solution D dropwise to solution C under stirring, and continuously stirred for 20 minutes to obtain suspension E; move suspension E to a polytetrafluoroethylene-lined stainless steel reactor, Hydrothermal reaction was carried out at 180°C for 18 hours. After the reaction, cool to room temperature, and then dry at 90°C for 10 hours to obtain Li 4 Ti 5 o 12 Precursor, and finally the obtained precursor was ground and heat-treated in a muffle furnace at 600 °C for 3 hours to obtain ultrathin Li 4 Ti 5 o 12 nanosheet materials, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com