Method for preparing composite anode material of super capacitor lithium titanate

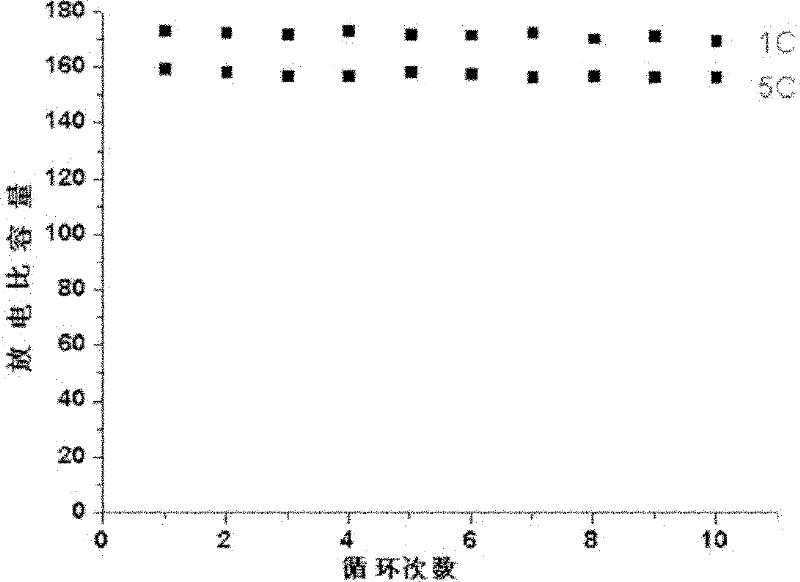

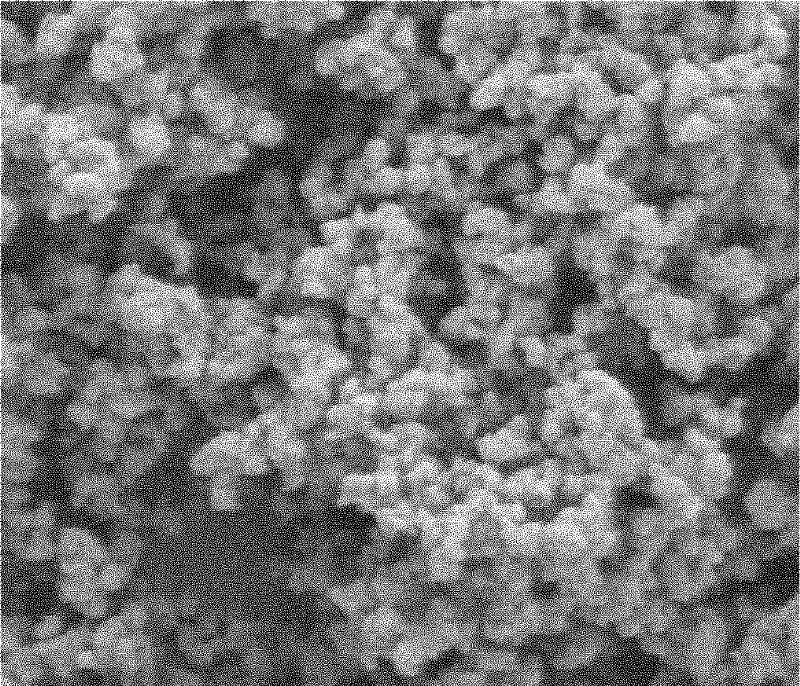

A technology for supercapacitors and negative electrode materials, applied in the field of materials, can solve the problems of complex process, large capacity attenuation, complicated steps, etc., and achieve the effects of simple process steps, uniform particle distribution, and high safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preparation method of the supercapacitor lithium titanate composite negative electrode material comprises the following steps:

[0021] A. According to Li 4 Ti 5 o 12 The mass ratio of each element in is weighed Li respectively 2 CO 3 Powder, TiO 2 Powder and appropriate amount of dispersant. More specifically, Li 2 CO 3 Powder, TiO 2 The weight ratio of powder and dispersant is 3:7.5:(9-19). The dispersant is alcohol, and the concentration of the alcohol is not limited, and usually the concentration is not less than 50wt%. The function of alcohol is to make Li 2 CO 3 Powder and TiO 2 The powder is mixed well.

[0022] B. Put the above raw materials into a mixing tank for mixing, then put them into a ball mill for ball milling, dry the milled materials, then sinter, and cool to room temperature after sintering. More specifically, put the mixed raw materials into a planetary ball mill for ball milling for 7.5-8.5 hours, take them out and dry them in an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com