Air blowing method for controlling vortex-induced vibration of large-span bridge steel box girder

A steel box girder and long-span technology, applied in mechanical vibration control, bridge, non-electric variable control, etc., can solve problems such as inability to achieve the best control effect, achieve significant social and economic benefits, high degree of automation, and obvious control effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

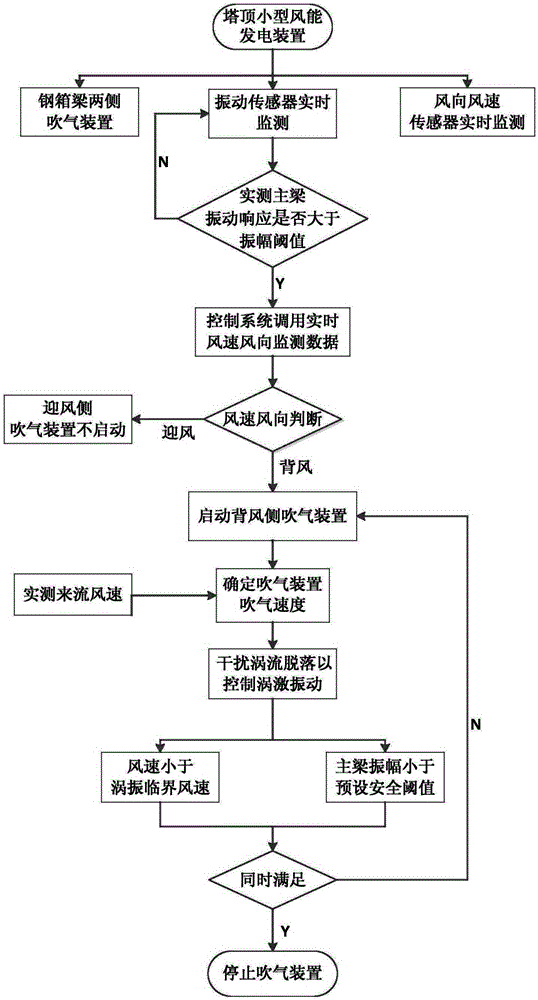

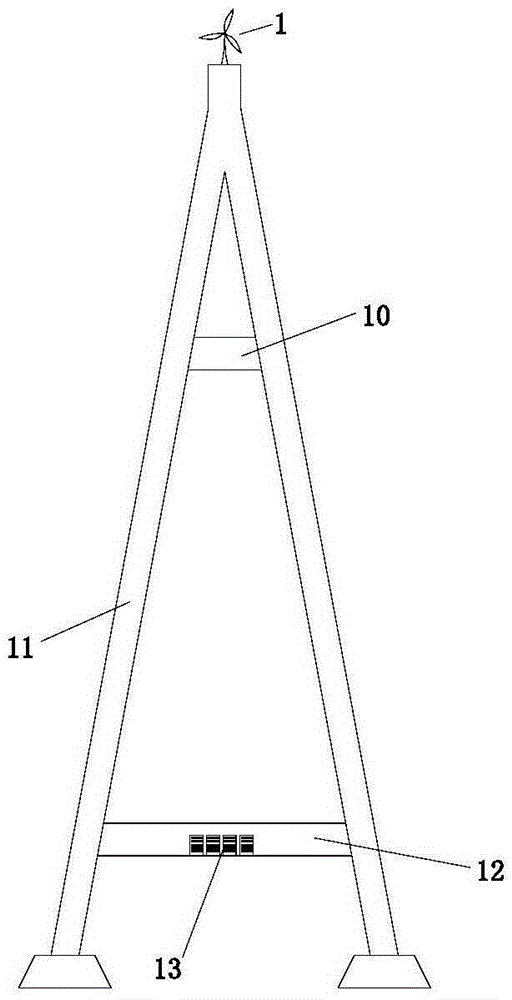

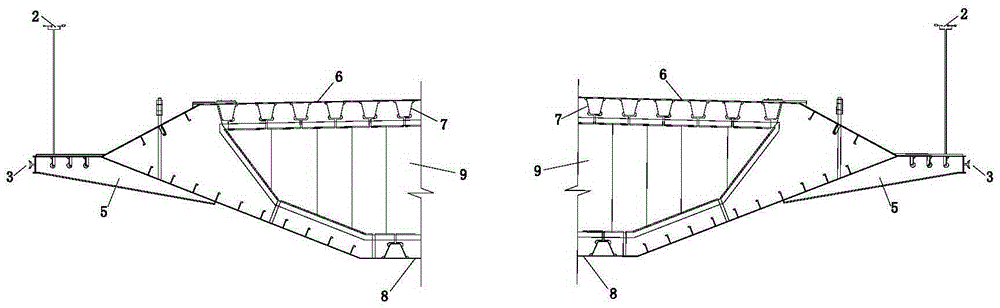

[0022] The main process of the realization scheme of the present invention is specifically as follows (see figure 1 ):

[0023] In the present invention, the wind energy generating device 1 is installed on the top of the tower column 11 to absorb natural wind energy and provide power output for the control system 13, the air blowing device 3, the vibration sensor 4 and the wind speed and direction sensor 2. For the energy supply method and principle, please refer to this research group The original authorized patent achievement "A Self-supply Energy System for Long-span Bridges Based on Wind Energy Effect" (invention patent number: ZL201210566841X), see the installation layout for details figure 2 . The control system 13 is installed inside the lower beam 12 of the pylon, and the installation layout is detailed in figure 2 . The air blowing device 3 and the wind speed and direction sensor 2 are installed on the air nozzles 5 of the steel box girder on both sides, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com