Novel environment-friendly noise-free brake pad and machining method thereof

A processing method and technology for brake pads, applied in the field of automobile brake pads, can solve the problems of adverse effects of high temperature friction performance stability, heat loss of asbestos-based brake pads, poor braking comfort, etc. Comfortable movement and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

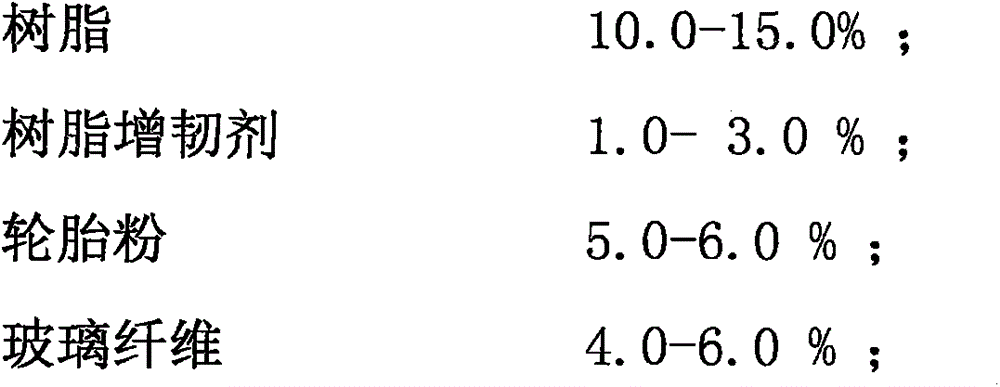

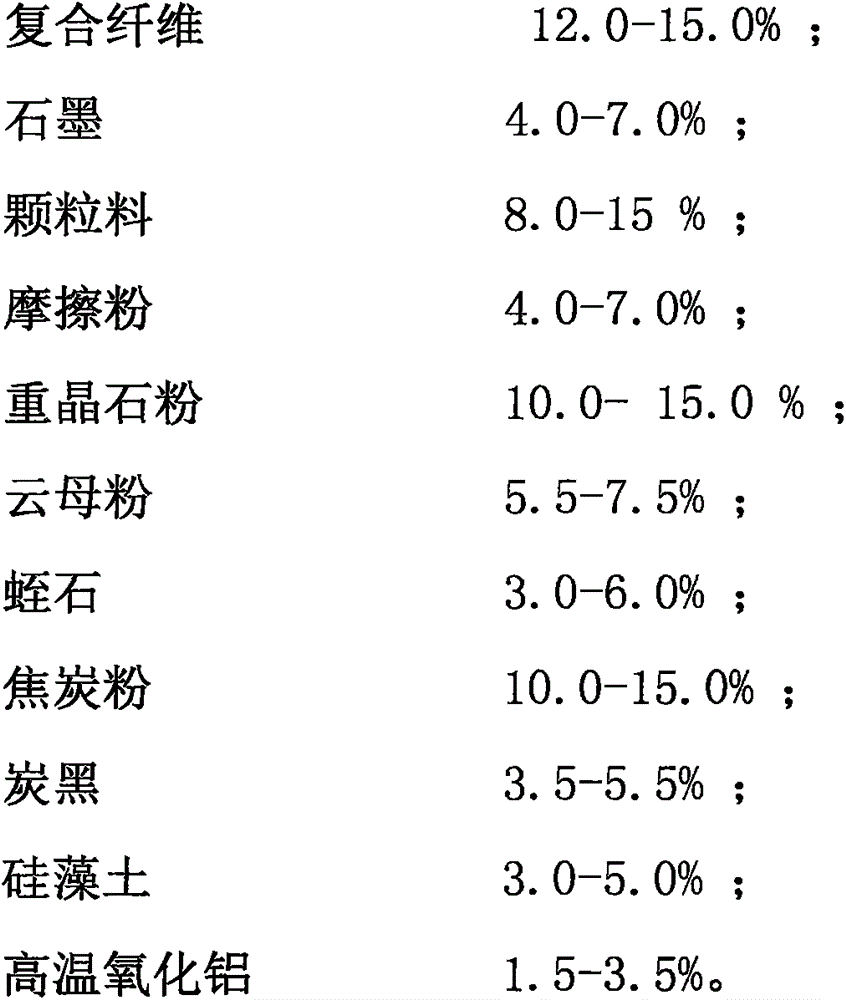

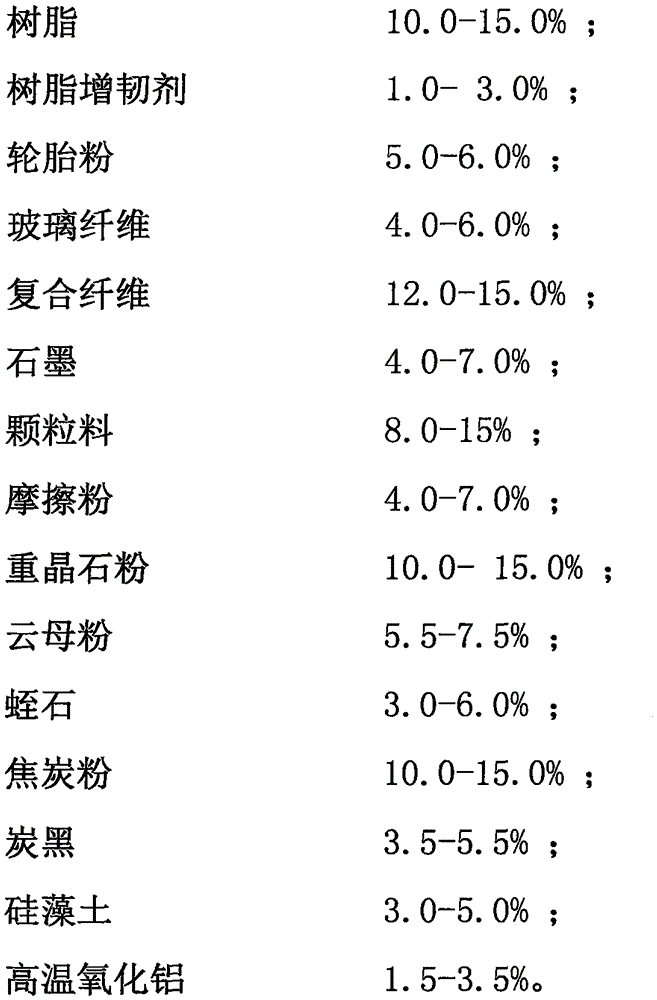

Method used

Image

Examples

Embodiment 1

[0028] Example 1. The material of the brake pad includes the following components by weight: 10 parts of resin, 3 parts of resin toughening agent, 5 parts of tire powder, 4 parts of glass fiber, 15 parts of composite fiber, 6 parts of graphite, 8 parts of granular material, and 6 parts of friction powder , 10 parts of barite powder, 7 parts of mica powder, 3 parts of vermiculite, 13 parts of coke powder, 5 parts of carbon black, 3 parts of diatomaceous earth, and 2 parts of high-temperature alumina.

[0029] Among them, the flow distance of the resin is 40-50mm, the fiber length of the glass fiber is 6mm, the fiber length of the composite fiber is 2-9mm, the graphite is 100 mesh, the granular material is 20-40 mesh, and the friction powder is 40 mesh; The spar powder is 325 mesh, the mica powder is 100 mesh, the vermiculite is 40 mesh, the coke powder is 60 mesh, the carbon black is 325 mesh, the diatomite is 325 mesh, and the high temperature alumina is 325 mesh.

[0030] Th...

Embodiment 2

[0041] Example 2. The material of the brake pad includes the following components by weight: 12 parts of resin, 3 parts of resin toughening agent, 5 parts of tire powder, 4 parts of glass fiber, 13 parts of composite fiber, 4 parts of graphite, 10 parts of granular material, 6 parts of friction powder , 10 parts of barite powder, 7 parts of mica powder, 3 parts of vermiculite, 13 parts of coke powder, 5 parts of carbon black, 3 parts of diatomaceous earth, and 2 parts of high-temperature alumina.

[0042] Among them, the flow distance of the resin is 40-50mm, the fiber length of the glass fiber is 6mm, the fiber length of the composite fiber is 2-9mm, the graphite is 100 mesh, the granular material is 20-40 mesh, and the friction powder is 40 mesh; The spar powder is 325 mesh, the mica powder is 100 mesh, the vermiculite is 40 mesh, the coke powder is 60 mesh, the carbon black is 325 mesh, the diatomite is 325 mesh, and the high temperature alumina is 325 mesh.

[0043] The p...

Embodiment 3

[0054]Example 3. The material of the brake pad includes the following components by weight: 13 parts of resin, 3 parts of resin toughening agent, 5 parts of tire powder, 4 parts of glass fiber, 12 parts of composite fiber, 6 parts of graphite, 15 parts of granular material, 4 parts of friction powder , 10 parts of barite powder, 6 parts of mica powder, 3 parts of vermiculite, 10 parts of coke powder, 4 parts of carbon black, 3 parts of diatomaceous earth, and 2 parts of high-temperature alumina.

[0055] Among them, the flow distance of the resin is 40-50mm, the fiber length of the glass fiber is 6mm, the fiber length of the composite fiber is 2-9mm, the graphite is 100 mesh, the granular material is 20-40 mesh, and the friction powder is 40 mesh; The spar powder is 325 mesh, the mica powder is 100 mesh, the vermiculite is 40 mesh, the coke powder is 60 mesh, the carbon black is 325 mesh, the diatomite is 325 mesh, and the high temperature alumina is 325 mesh.

[0056] The pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com