A passive hydraulic braking system

A hydraulic brake and hydraulic brake technology, applied in fluid pressure actuation system testing, fluid pressure actuation system safety, brake actuators, etc., can solve problems such as short safe operation time, increased equipment maintenance, and many valve groups , to achieve the effect of prolonging the safe running time, reducing the maintenance difficulty and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

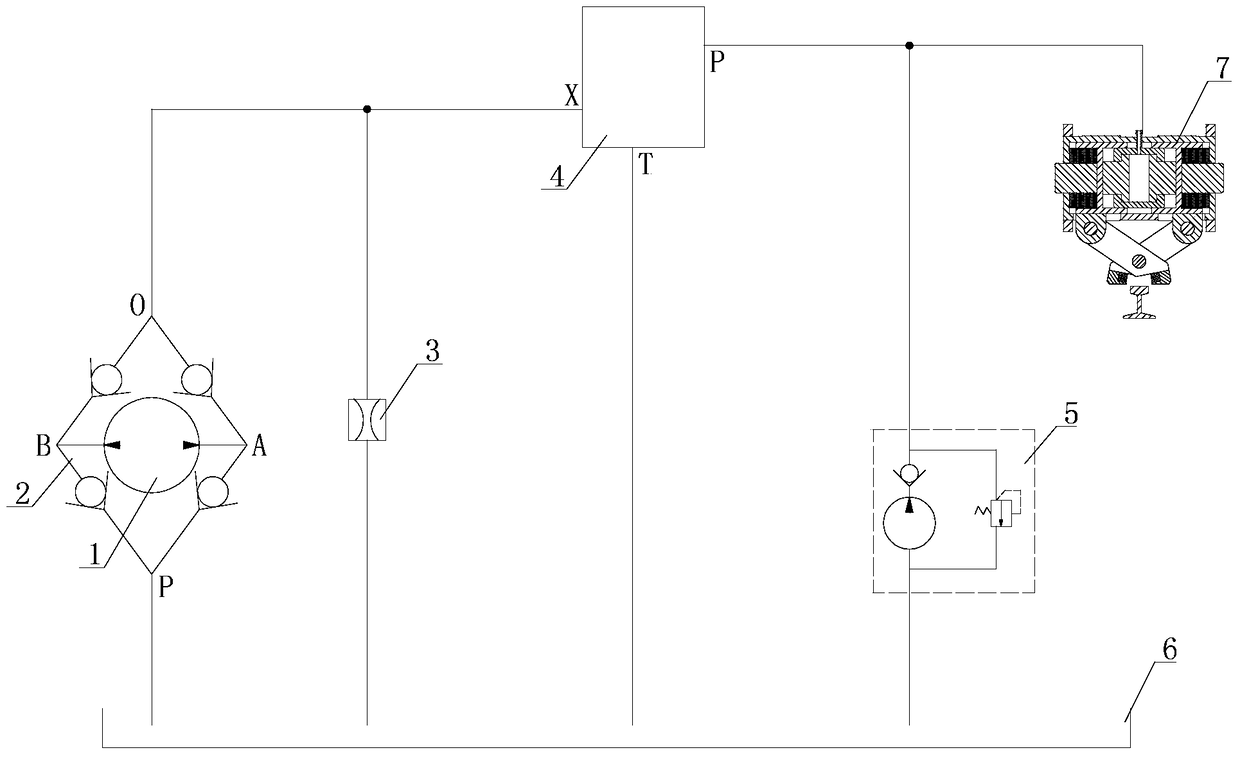

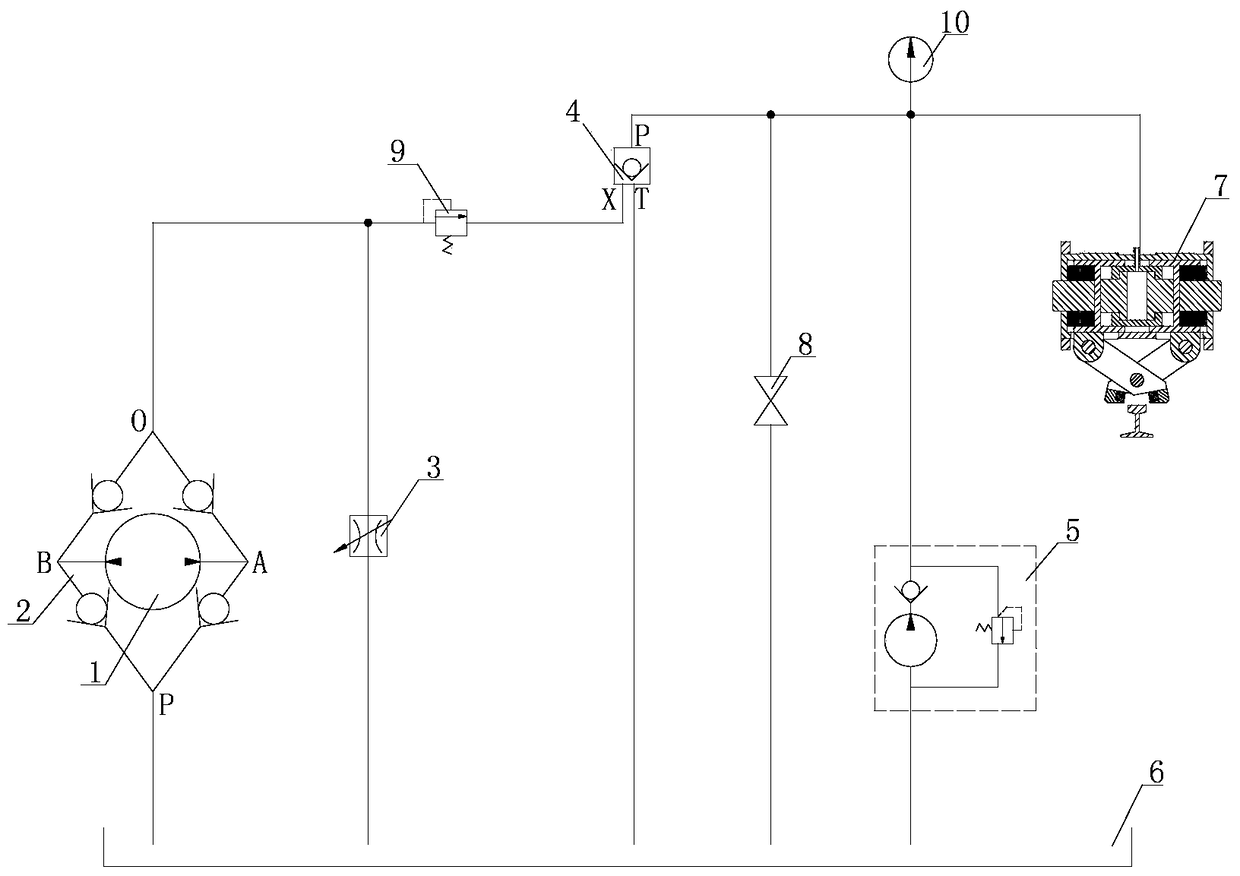

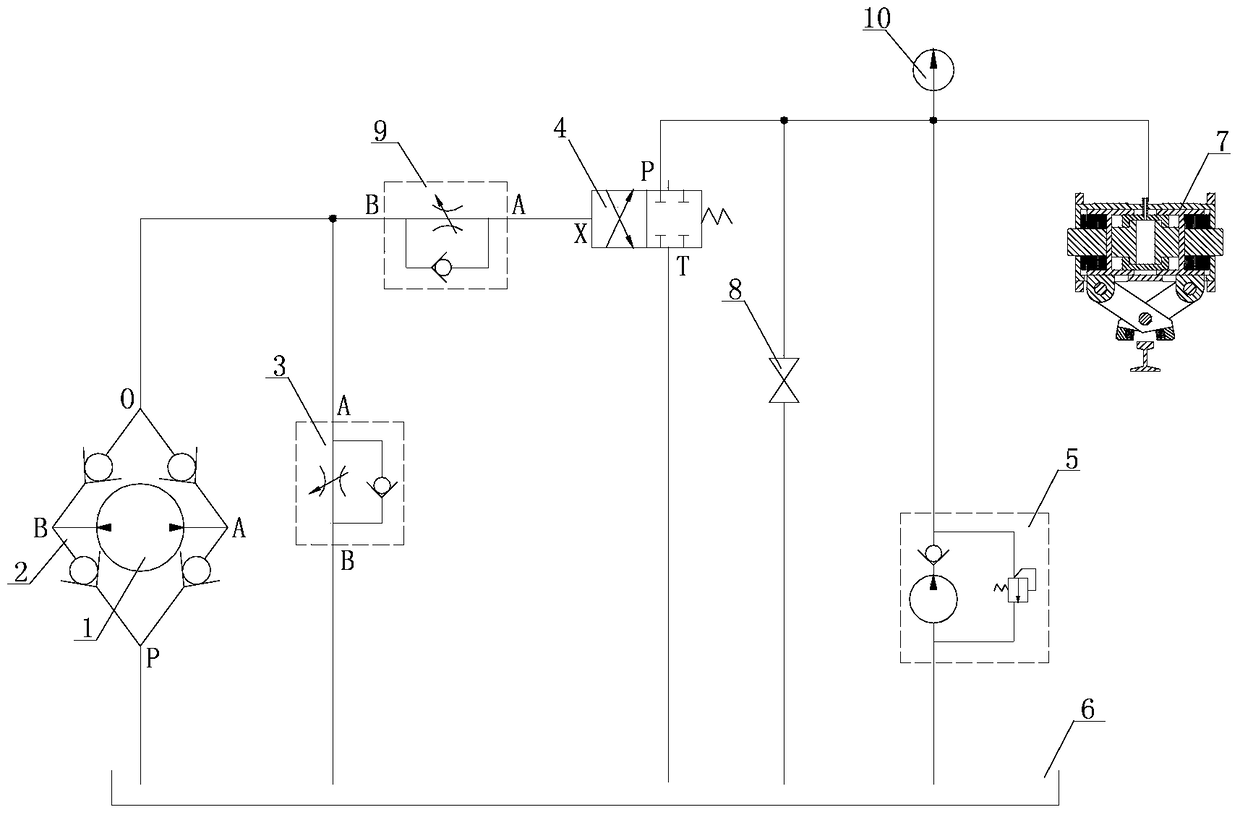

[0015] Such as figure 1 , figure 2 , image 3 As shown, a passive hydraulic braking system includes an oil pump 1; a hydraulic bridge 2; a flow control device 3; a pressure relief device 4 with a pressure maintaining function; a hydraulic brake 7; a hand pump 5; a fuel tank 6;

[0016] The oil inlet and outlet of the oil pump 1 are connected to ports A and B of the hydraulic bridge 2 through oil pipes, the oil inlet P of the hydraulic bridge 2 is connected to the oil tank 6 through the oil pipe, and the oil outlet O of the hydraulic bridge 2 is connected to the oil tank 6 through the flow control device 3 , The oil outlet O of the hydraulic bridge 2 is connected to the control oil port X of the pressure relief device 4 with the pressure maintaining function, and the oil discharge port T of the pressure relief device 4 with the pressure maintaining function is connected to the fuel tank 6, and the pressure relief device with the pressure maintaining function The oil inlet P ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com