Lower-guide type main-truss-free hanging basket

A down-guiding and beam-guiding technology, which is applied in construction, bridge construction, bridges, etc., can solve the problems of twisting and deformation of hanging baskets, heavy weight of hanging baskets, and large quantities, so as to reduce weight, save steel (steel) investment, and small volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

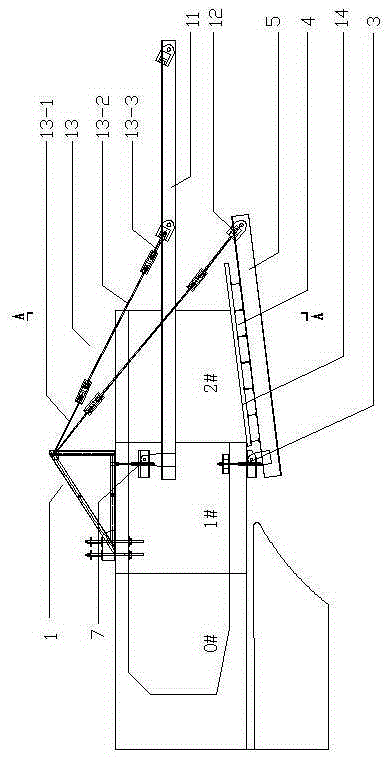

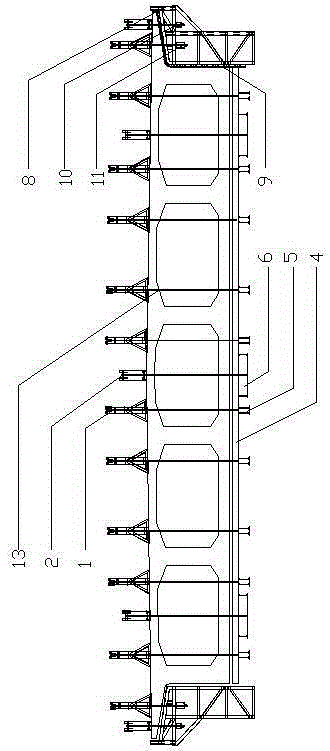

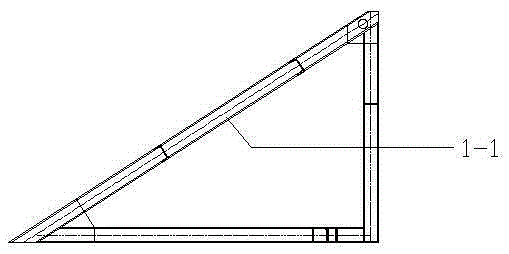

[0038] As shown in the accompanying drawings, the hanging basket without main truss of the present invention comprises a tripod support mechanism, a bottom basket mechanism, a side form mechanism and a connection mechanism. The tripod support mechanism is arranged on the top of the completed box girder, The bottom basket mechanism is arranged at the lower part of the bottom plate of the completed box girder, the side formwork mechanism is arranged at the left and right sides of the completed box girder, and the connecting mechanism connects and hangs the bottom basket mechanism and the side form mechanism under the tripod support mechanism.

[0039] By setting the present invention into a structural form comprising a tripod support mechanism, a bottom basket mechanism, a side form mechanism and a connection mechanism, the tripod support mechanism is used to support the bottom basket mechanism and the side form mechanism located below the tripod support mechanism through the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com