Method for preparing phenolic acid compound through fatsia japonica

An octagonal gold plate and phenolic acid technology are applied in the field of biotransformation of natural products to achieve the effects of large biomass, broad application prospects and wide planting area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

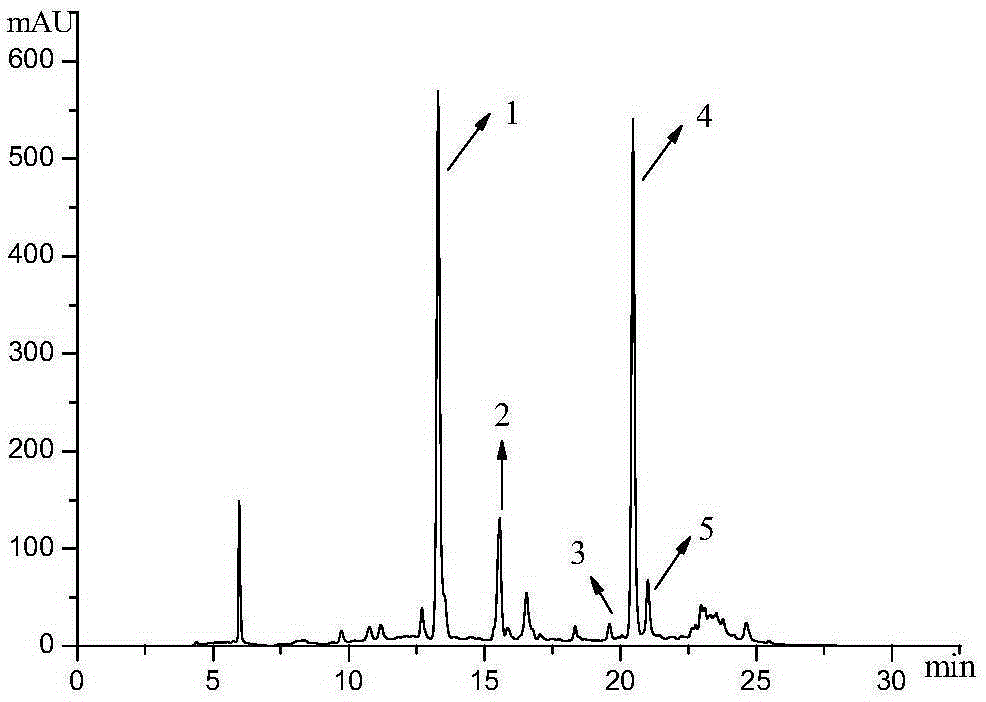

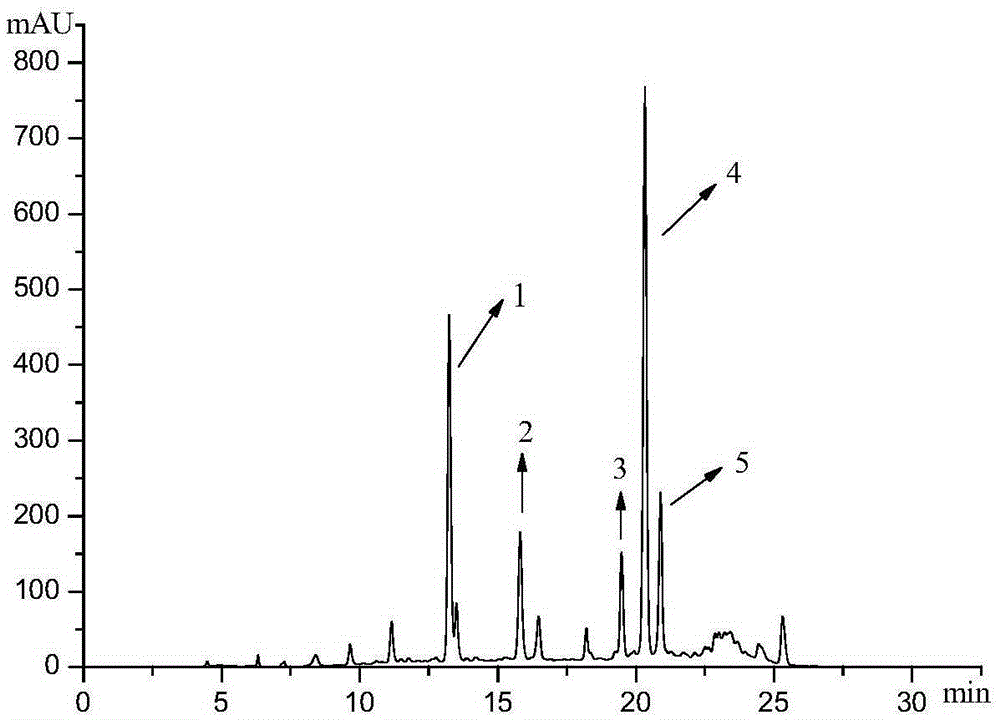

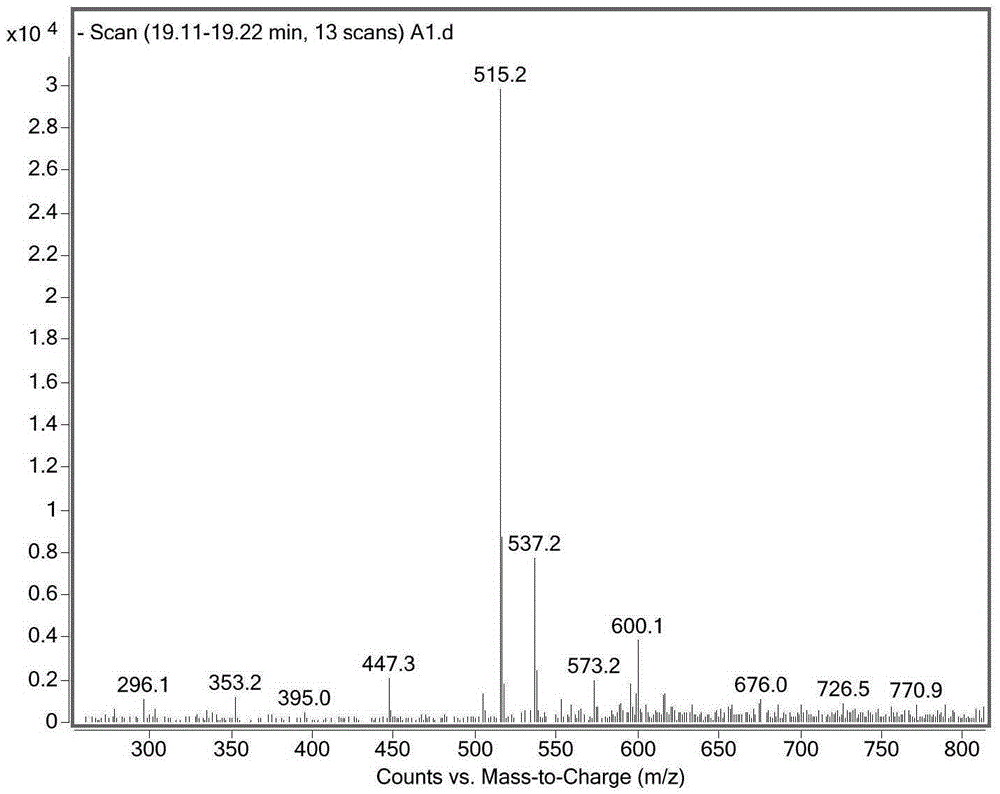

[0042] 500g of star anise golden pan fruit was crushed through a 60-mesh sieve, and 70% ethanol solution was added according to the ratio of solid to liquid at 1:20, ultrasonically extracted, and rotary evaporated until ethanol-free. The extract was extracted with ethyl acetate to obtain an extract containing 3,4-dicaffeoylquinic acid, 3,5-dicaffeoylquinic acid, 4,5-dicaffeoylquinic acid, and quinic acid And raffinate containing chlorogenic acid, caffeic acid, quinic acid. After the organic solvent of the extract was removed, further separation and purification by column chromatography obtained 0.28 g of 3,4-dicaffeoylquinic acid with a purity of 85%, and 2.9 g of 3,5-dicaffeoylquinic acid with a purity of 92%. 0.23g of 90% 4,5-dicaffeoylquinic acid, caffeic acid, quinic acid and other products can be obtained from the raffinate.

Embodiment 2

[0044] Same as in Example 1, the ethanol solution with a volume fraction of 70% was replaced with a methanol solution with a volume fraction of 70%.

Embodiment 3

[0046] 500g of star anise golden pan fruit was crushed through a 60-mesh sieve, and 70% ethanol solution was added according to the ratio of solid to liquid 1:20, ultrasonically extracted for 1 hour, and the operation was repeated once. The extract was extracted in equal proportions with ethyl acetate to obtain 3,4-dicaffeoylquinic acid, 3,5-dicaffeoylquinic acid, 4,5-dicaffeoylquinic acid, and quinic acid Extract and raffinate containing chlorogenic acid, caffeic acid, quinic acid. After the organic solvent of the extract was removed, the AB-8 macroporous resin was further separated and purified to obtain 0.31 g of 3,4-dicaffeoylquinic acid with a purity of 90%, and 2.85 g of 3,5-dicaffeoylquinic acid with a purity of 96%. g, 0.37 g of 4,5-dicaffeoylquinic acid with a purity of 90%, caffeic acid, quinic acid and other products can also be obtained from the raffinate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com