Hybrid curing peelable coating material and preparation method thereof

A hybrid curing and coating technology, used in anti-corrosion coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of easy inhibition by oxygen, poor adhesion, low precision, etc., and achieves short drying time, easy Control, the effect of drying faster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

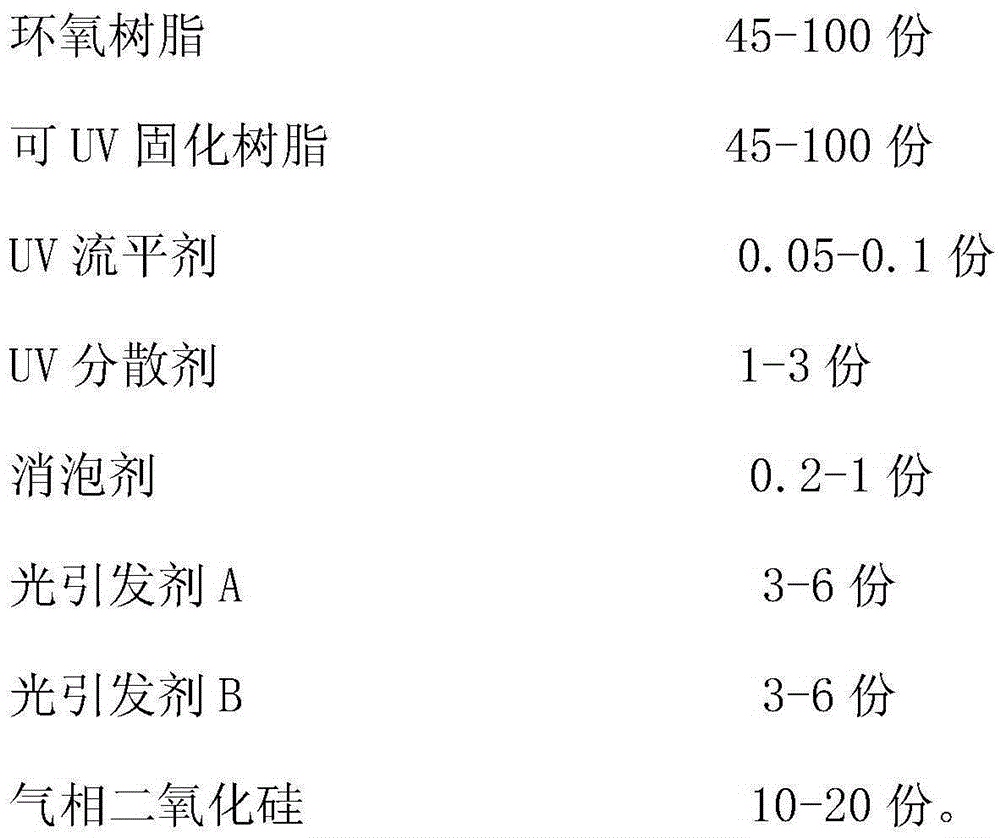

[0039] A kind of hybrid cured strippable coating, calculated by weight, its raw material composition and content are as follows:

[0040]

[0041] Wherein, the epoxy resin is a mixture of Daicel CEL2021P and TTA22 cycloaliphatic epoxy resin provided by Jiangsu Taitel New Material Technology Co., Ltd. in a mass ratio of 2:1;

[0042] Described UV curable resin is the mixture that epoxy acrylate and polyurethane acrylate form by mass ratio 2:1;

[0043] Described photoinitiator A is BASF Irgacure184D, Irgacure369, Irgacure819, the mixture that forms by mass ratio 1:1:1;

[0044] The photoinitiator B is the photoinitiator sulfonium salt Easepi6992 provided by Shanghai Guangyi Chemical Company;

[0045] The UV leveling agent is German BYK BYK-348;

[0046] Described UV dispersant is the NP-100 of U.S. Dow Company;

[0047] Described defoamer is the NopcoNXZ of German Henkel Company;

[0048] Described fumed silica is German Degussa hydrophobic silica R972;

[0049]The abov...

Embodiment 2

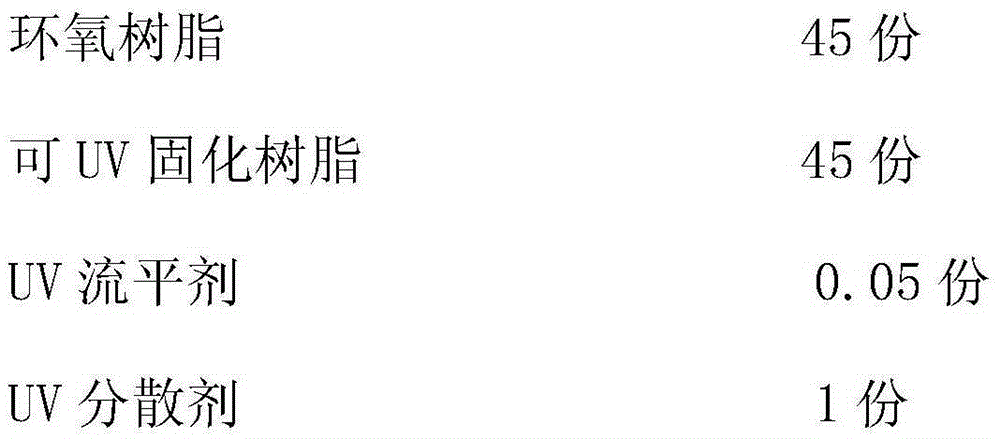

[0054] A kind of hybrid cured strippable coating, calculated by weight, its raw material composition and content are as follows:

[0055]

[0056]

[0057] Wherein, the epoxy resin is JZ-501 epoxy resin of Nanjing Jiazhong Chemical Technology Co., Ltd.;

[0058] The UV curable resin is polyurethane acrylate;

[0059] Described photoinitiator A is the mixture that BASF Irgacure1173 and IrgacureTPO form by mass ratio 1:1;

[0060] The photoinitiator B is a mixture of photoinitiator sulfonium salt Easepi6992 and Irgacure250 provided by Shanghai Guangyi Chemical Co., Ltd. in a mass ratio of 1:1;

[0061] The UV leveling agent is German BYK-344;

[0062] Described UV dispersant is German BYK333 leveling agent;

[0063] Described defoamer is the NopcoNXZ of German Henkel Company;

[0064] The fumed silica is Cabot fumed silica CAB-O-SILM-5;

[0065] The preparation method of the above-mentioned a kind of hybrid curing peelable coating specifically includes the following s...

Embodiment 3

[0070] A kind of hybrid cured strippable coating, calculated by weight, its raw material composition and content are as follows:

[0071]

[0072] The preparation method of this hybrid curing strippable coating comprises the following steps: according to the formula, add 1 part of UV dispersant and 0.3 part of defoamer in the GFJ-0.4 type high-speed disperser (Shanghai Xinnuo Instrument Equipment Co., Ltd.), and pass through 700r Disperse for 18 minutes at a rotating speed of 2100r / min, then add 16 parts of fumed silica, reduce the rotating speed to 300r / min, add 70 parts of epoxy resin, 70 parts of UV curable resin and the remaining 0.3 parts of defoamer, 1 part of UV dispersant, 0.08 parts of UV leveling agent, 4 parts of photoinitiator A, 4 parts of photoinitiator B, and stir evenly, continue to disperse for 8 minutes, after mixing evenly, pass through GS450 small vibrating screen (Laizhou Jingtai Chemical Machinery Factory) filter to remove the filter residue to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com