Decolorization and purification technology for sodium dehydroacetate

A technology of sodium dehydroacetate and dehydroacetic acid, which is applied in the field of fine chemicals, can solve problems such as poor operating environment, product loss, and high labor intensity, and achieve high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

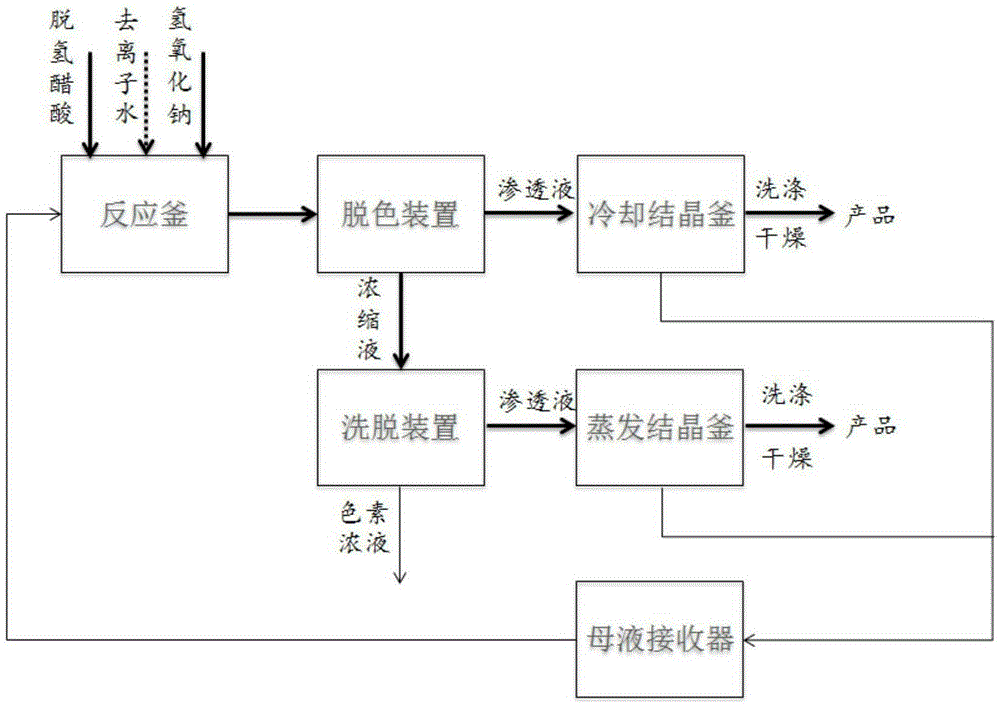

[0032](1) drop into 1000g deionized water and the dehydroacetic acid crude product 1000g of mass fraction about 95% in the reactor, start stirring, adjust the stirring intensity to be 100rpm, and slowly drip the mass fraction is 1250g of aqueous sodium hydroxide solution of 18%, After the sodium hydroxide solution in the metering tank is added dropwise, open the steam jacket, gradually raise the temperature to 90° C., and stir at this temperature for 1 hour. At this time, the measured pH of the solution is 8.1, and the light transmittance is 50%;

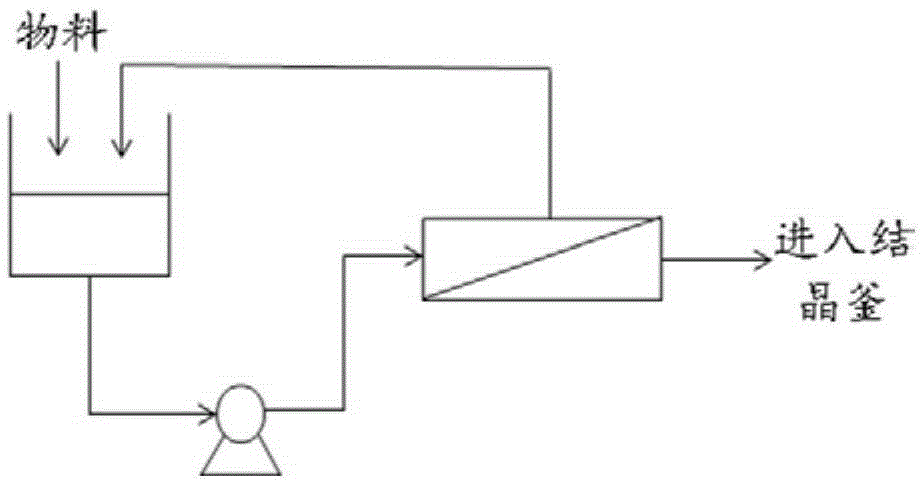

[0033] (2) the sodium dehydroacetate synthetic material that last step obtains is transported to ceramic nanofiltration membrane decolorization device (as figure 2 shown), using ZrO with a molecular weight cut-off of 200Da 2 Sheet-type ceramic nanofiltration membrane, the control operating pressure is 1MPa, the system operating temperature is 90°C, the membrane surface flow rate is 3m / s, the pigment impurities in the material are c...

Embodiment 2

[0037] (1) 1200g of deionized water and 1000g of dehydroacetic acid crude product with a mass fraction of about 92.5% are dropped into the reactor, and the stirring is started, and the stirring intensity is adjusted to be 200rpm, and 1050g of aqueous sodium hydroxide solution with a mass fraction of 23% is slowly added dropwise, After the sodium hydroxide solution in the metering tank is added dropwise, open the steam jacket, gradually heat up to 85°C, and stir at this temperature for 1.5h. At this time, the measured pH of the solution is 9.2, and the light transmittance is 41%.

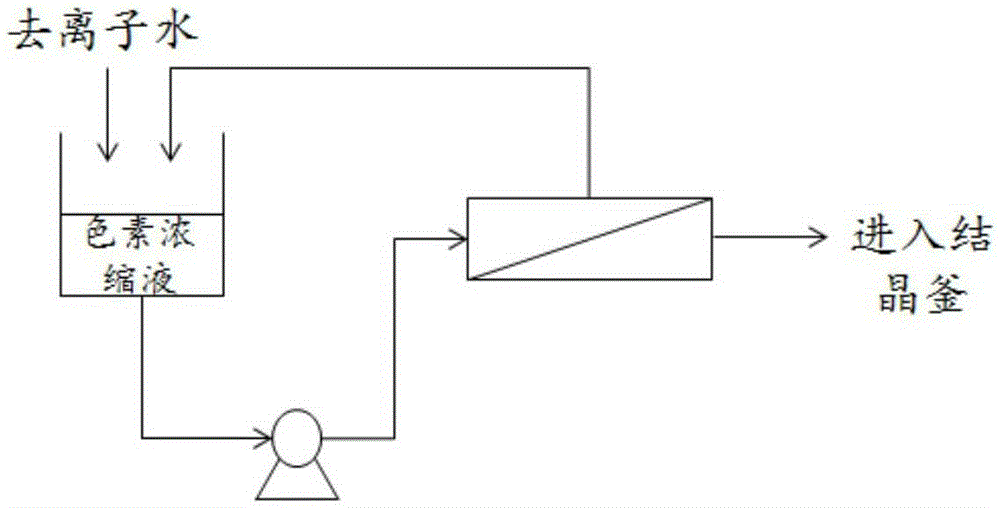

[0038] (2) the sodium dehydroacetate synthetic material that last step obtains is transported to ceramic nanofiltration membrane decolorization device (as Figure 4 shown), using 19-channel Al with a molecular weight cut-off of 400Da 2 o 3 Ceramic nanofiltration membrane, the control operating pressure is 1MPa, the system operating temperature is 85°C, the membrane surface flow rate is 4m / s, the pig...

Embodiment 3

[0042] (1) drop into 2100g deionized water and 1400g of crude product of dehydroacetic acid of mass fraction about 90% in the reactor, start to stir, adjust the stirring intensity to be 300rpm, and slowly add dropwise the mass fraction of 30% sodium hydroxide aqueous solution 1200g, After the sodium hydroxide solution in the metering tank is added dropwise, open the steam jacket, gradually heat up to 80° C., and stir at this temperature for 1 hour. At this time, the pH of the solution is measured to be 9, and the light transmittance is 34%.

[0043] (2) The sodium dehydroacetate synthesis material obtained in the previous step is transported to the ceramic nanofiltration membrane decolorization device, and the molecular weight cut-off is 300Da using 19 channel ZrO 2 -TiO 2 Ceramic nanofiltration membrane, the arrangement of membrane modules is 1 stage and 5 sections, the control operating pressure is 1.5MPa, the system operating temperature is 80°C, the membrane surface flow r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com