Method using micro reactor to prepare 1-chloro-1'-chloroacetyl cyclopropane

A chloroacetylcyclopropane, microreactor technology, applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of organic compounds, etc., can solve the problem of long reaction operation time, increase of "three wastes", poor reaction selectivity, etc. problems, to achieve the effect of mild conditions, environmental friendliness, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

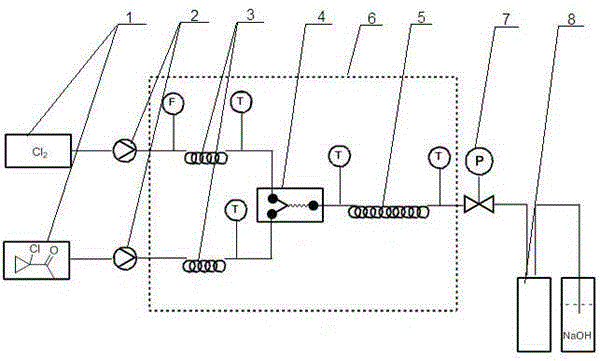

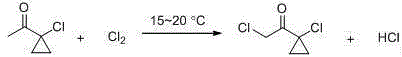

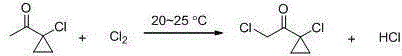

[0022] The application also provides a preparation method of 1-chloro-1'-chloroacetylcyclopropane, that is, using 1-chloro-1'-acetylcyclopropane and chlorine gas as raw materials to realize the chlorine of the α-position hydrogen atom in the microchannel A substitution reaction to generate 1-chloro-1'-chloroacetylcyclopropane can be carried out under solvent-free or solvent-free conditions. However, it is preferably carried out under solvent-free conditions. Specifically, the microreactor device is used to prepare the method for 1-chloro-1 '-chloroacetylcyclopropane, comprising the steps:

[0023] 1) Prepare the raw materials 1-chloro-1′-acetylcyclopropane and chlorine gas for later use;

[0024] 2) Feed the raw materials through different feed pumps according to a certain ratio, and react through the micro-reaction channel. The reaction time is 0.15-10min, the temperature is -20-100°C, and the pressure is 1-2atm;

[0025] 3) The flow state of the mixed liquid in step 2) is ...

Embodiment 1

[0027]

[0028] Adjust the temperature of the temperature control device to 10°C and the system pressure to 1 atm. Under the condition of no solvent, adjust the flow rate of the substrate to 10mol / h, the flow rate of chlorine gas to 10.5~11mol / h, and use a metering pump to inject the material into the reaction system. Reaction, according to the requirements of the reaction, the control reaction time is 30s. As the reaction progressed, the temperature at the outlet of the reactor gradually increased to 25°C, and the temperature at the outlet of line 2 increased to 20°C. After 2 hours of reaction, samples were taken for gas phase analysis. The GC normalized purity of the product was 99.2%, and the quantitative yield was 98.5%.

Embodiment 2

[0030]

[0031] Adjust the temperature of the temperature control device to 10°C, and the system pressure to 1 atm. Under the condition that the solvent is toluene, adjust the substrate flow rate to 1mol / h, the chlorine gas flow rate to 1.0~1.15mol / h, and use a metering pump to inject the material into the reaction system According to the requirements of the reaction, the reaction time is controlled to be 20s. As the reaction progressed, the temperature at the outlet of the reactor gradually increased to 30°C, and the temperature at the outlet of pipeline 2 increased to 20°C. After 1 hour of reaction, samples were taken for gas phase analysis. The GC normalized purity of the product was 97.6%, and the quantitative yield was 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com