A 4-element formula ultra-high bs manganese zinc ferrite material and preparation method

A manganese-zinc ferrite, ultra-high technology, applied in the field of 4-element formula ultra-high Bs manganese-zinc ferrite material and preparation, can solve the problem of high power loss of the magnetic core, to meet performance and cost requirements, low loss, The effect of low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

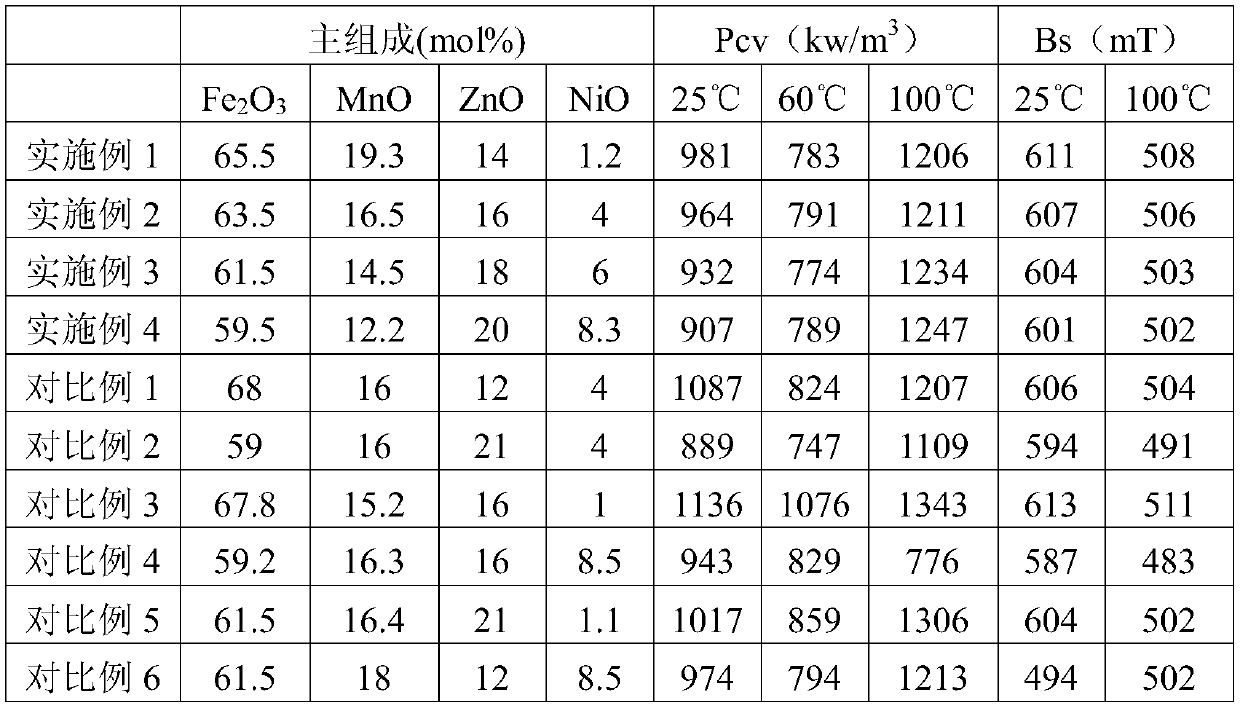

Embodiment 1

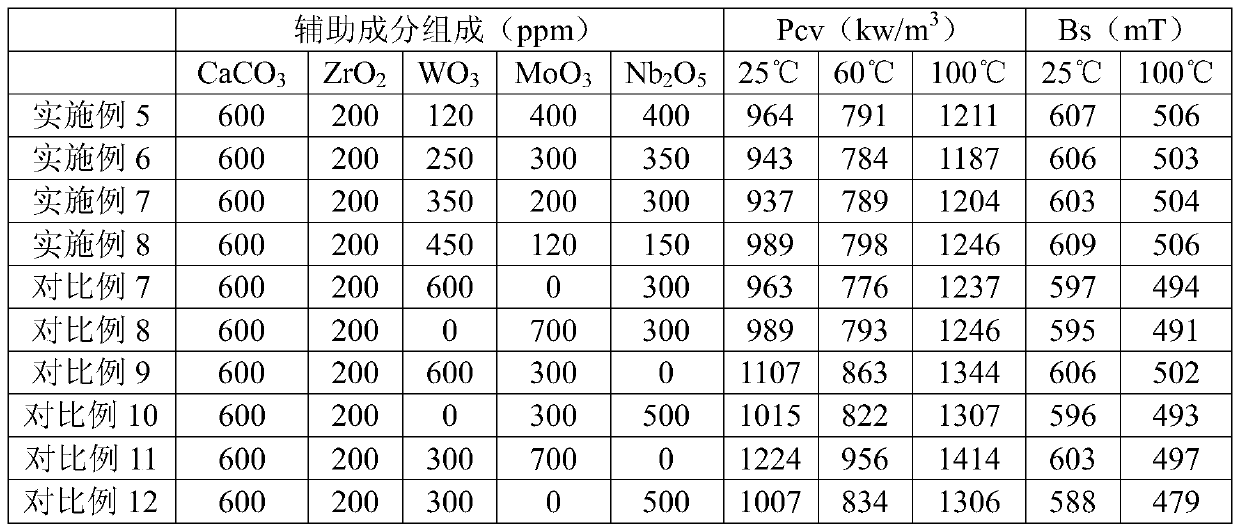

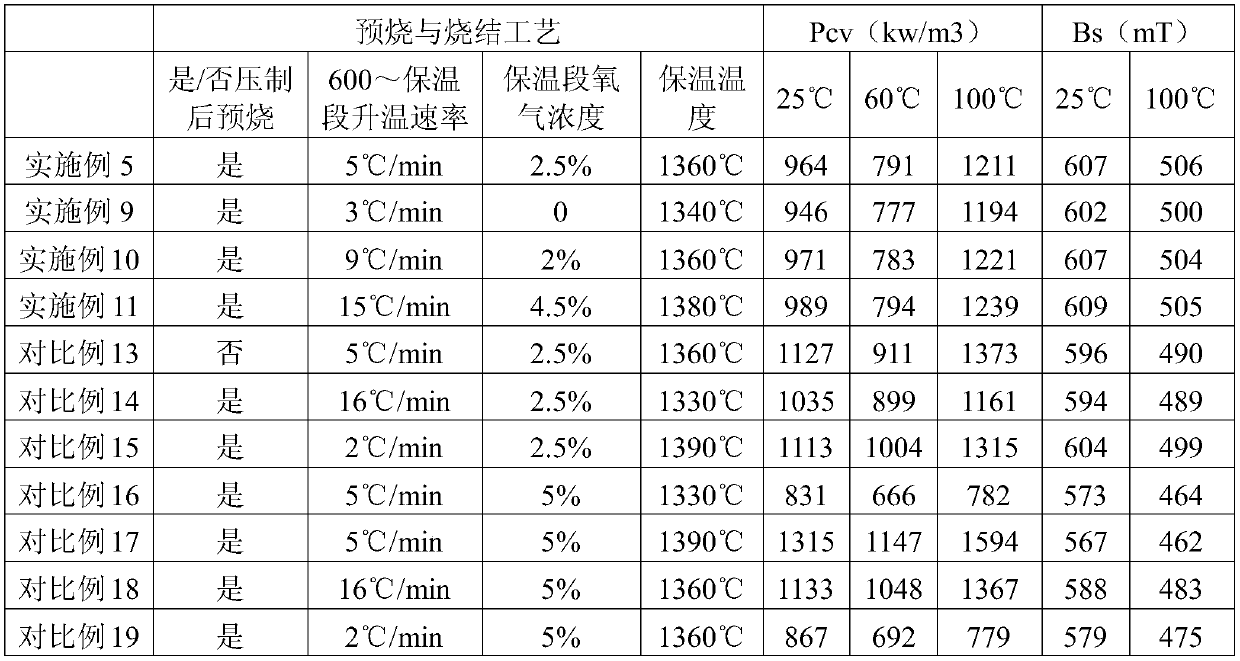

[0018] will consist of 65.5mol% Fe 2 o 3 , 19.3mol% of MnO, 14mol% of ZnO, and 1.2mol% of NiO were mixed in a sand mill for 1 hour. After drying, they were pressed into a round cake with an outer diameter of 100mm under a pressure of 10Mpa, and then dried at 800 Pre-fire at ℃ for 2 to 4 hours. Based on the quality of the powder after calcining, add auxiliary components to the above calcined material, the added auxiliary components (ppm) are: 600ppm of CaCO 3 , 200ppm ZrO 2 , 120ppm WO 3 , 200ppm MoO 3 , 400ppm Nb 2 o 5 . Then carry out secondary sanding for 140 minutes, and dry the secondary sanding slurry for particle size testing. SMD is 0.9-1.1 μm, X50 is 1-1.15 μm, and X90 is less than 3 μm. After adding PVA, carry out spray granulation, and the shape is Φ25* 15*8 standard ring cores are sintered. 600 ℃ ~ 1360 ℃ heating rate 5 ℃ / min, at 1360 ℃ for 6 hours, oxygen concentration 2.5%, according to the equilibrium oxygen concentration for atmosphere protection cool...

Embodiment 2

[0021] The formula is: 63.5mol% Fe 2 o 3 , 16.5 mol% of MnO, 16 mol% of ZnO, 4 mol% of NiO, the manufacturing process, sintering process and test conditions are the same as in Example 1.

Embodiment 3

[0023] The formula is: 61.5mol% Fe 2 o 3 , 14.5 mol% of MnO, 18 mol% of ZnO, 6 mol% of NiO, the manufacturing process, sintering process and test conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| core loss | aaaaa | aaaaa |

| core loss | aaaaa | aaaaa |

| core loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com