Preparation and distribution method of vacuum glass and supporter thereof

A vacuum glass and support technology, which is applied in the field of preparation and placement of vacuum glass and its supports, can solve the problems of affecting the quality and life of vacuum glass, uneven force on support points, and poor accuracy of supports, etc. The effect of small difference, guaranteed quality and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

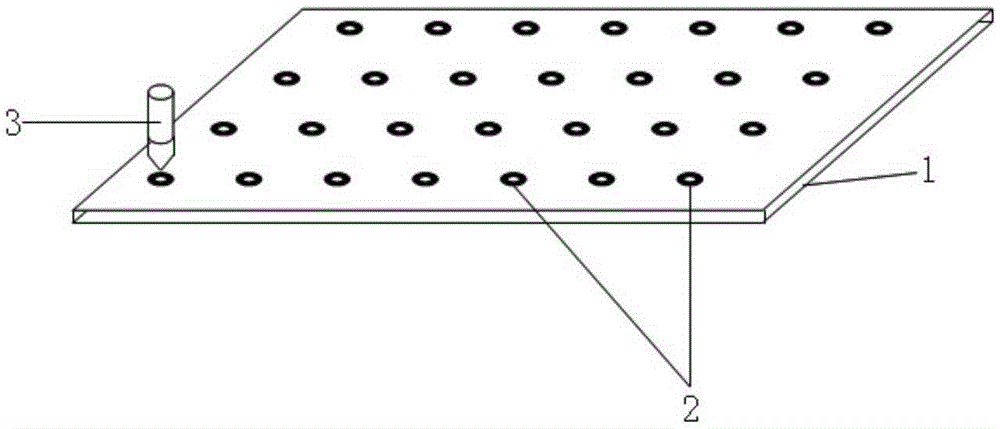

[0027] see figure 1 , the preparation and placement method of the vacuum glass support is as follows: a piece of glass 1 (size 1800mm*1500mm) will be cleaned and dried on the 3D printer printing table; the glass glaze is ground and passed through 200 Mesh sieve, then pack into the 3D printer feeding chamber; Use CAD drawing software to draw the three-dimensional graphics of support 2 and the three-dimensional graphics of support 2 arrangement, wherein the shape of support 2 is a cylinder with a bottom diameter of 1mm and a height of 0.1mm. The supports are arranged in an m×n matrix, and the distance between rows and columns of the matrix is 30mm. Start the 3D printer, and the nozzle 3 at the outlet of the 3D printer is equipped with a heating device to heat the glass glaze, control the temperature of the printer’s output, and control the output volume through the pressure device to print the molten glass glaze on the glass layer by layer. On the chip, the thickness of each ...

Embodiment 2

[0029] see figure 2 , the preparation and placement method of the vacuum glass support are as follows: a piece of glass 1 (size 1200mm*700mm) for making vacuum glass is cleaned and dried and placed on the 3D printer printing table; the screened metal powder is loaded into 3D printer feeding chamber; CAD drawing software is used to draw the three-dimensional graphics of the support 2 and the three-dimensional graphics arranged in the vacuum glass. The shape of the support 2 is a circular ring with a bottom outer diameter of 1 mm, an inner diameter of 0.8 mm, and a height of 0.2 mm. The supports are arranged in an m×n matrix, and the distance between rows and columns of the matrix is 40mm. Start the 3D printer, the heating device installed on the nozzle 3 at the discharge port of the 3D printer will heat the metal powder, control the discharge temperature of the printer, control the discharge volume through the pressure device, and print the molten metal layer by layer on th...

Embodiment 3

[0031] On the basis of Example 1 or Example 2, after the preparation and placement of the support is completed, the vacuum glass can be obtained by completing corresponding operations such as assembling according to the existing vacuum glass preparation method.

[0032] Since the preparation of the supports adopts 3D printing technology, the precision of the supports is high, and the height difference of each support is small, which ensures that after the vacuum glass is combined, each support point is in contact with two pieces of glass, and the support points are evenly stressed, reducing glass fragmentation probability of cracking. In addition, 3D printing technology is used to complete the preparation and layout of the vacuum glass support in one step. The whole process is controlled by computer, the process is simple, the accuracy is high, and various errors in manual operation are avoided. At the same time, the production process is reduced and the production efficiency i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com