Stub bar punching device

A technology of material head and punching die, which is applied in the field of material head punching device, can solve the problems of low production efficiency and achieve the effects of high production efficiency, good product consistency and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

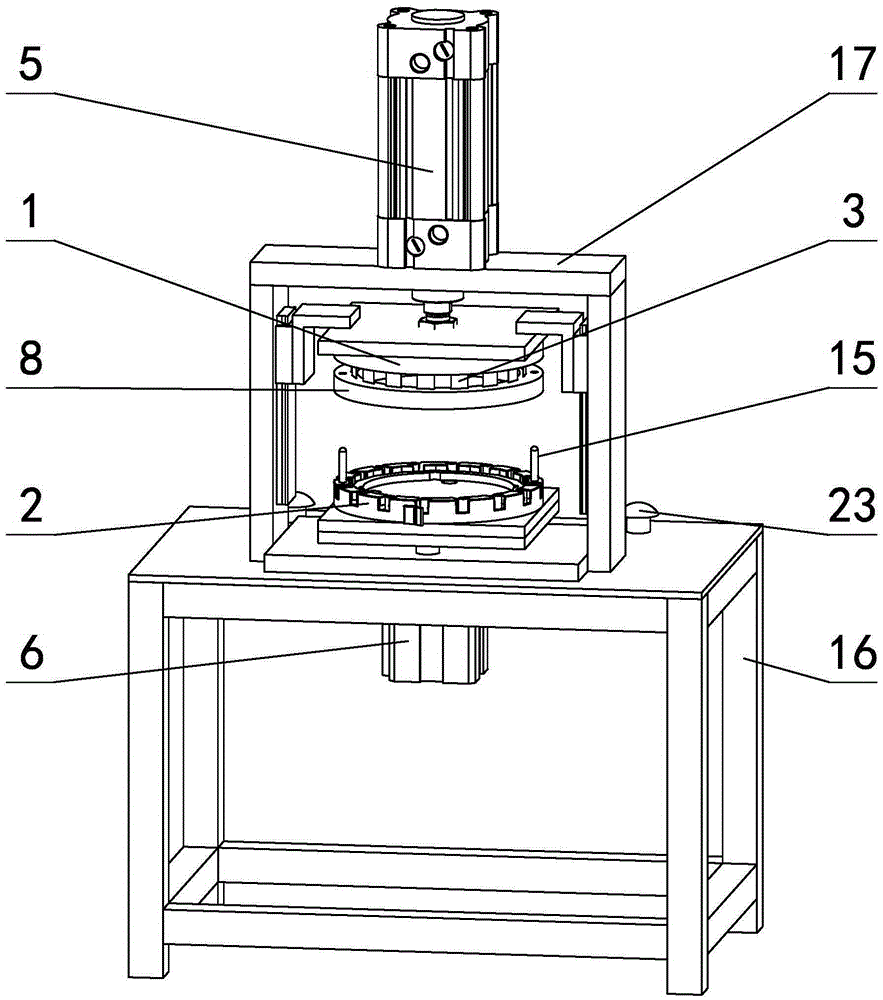

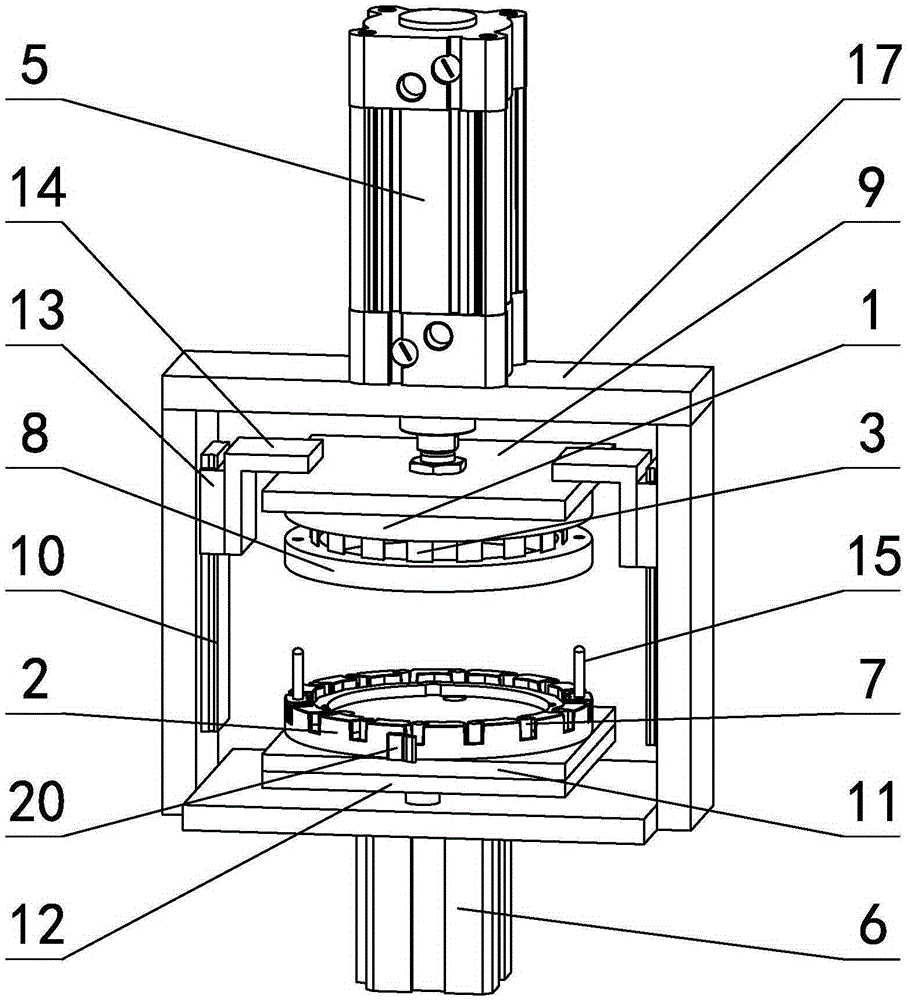

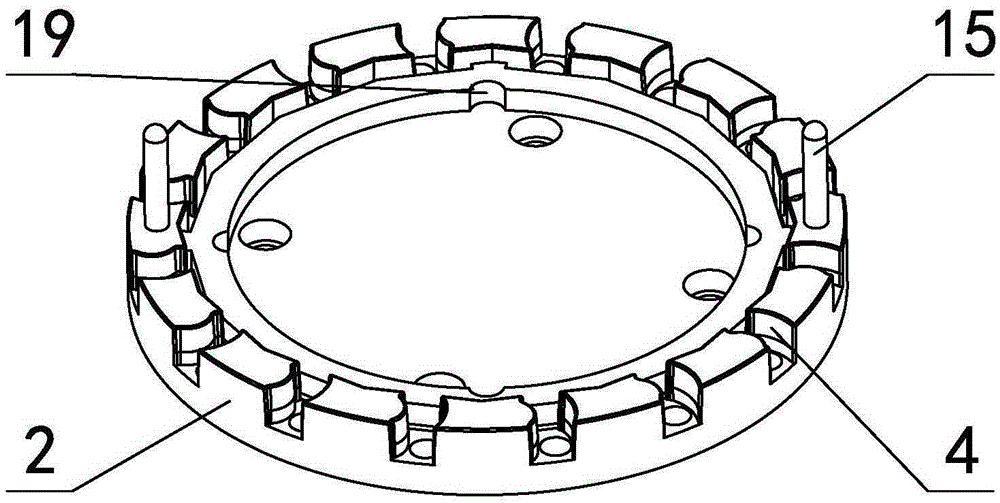

[0027] in such as figure 1 figure 2 In the shown embodiment 1, a kind of head punching device comprises a frame composed of a base 16 and a rectangular frame 17 arranged on the base, the frame is provided with an upper mold base 1 and The lower mold base 2, the upper mold base is circular, and the bottom surface of the upper mold base is provided with 16 punching dies 3 arranged in a ring, and the punching dies are cutting knives (see Figure 4 ), the cutting knives are evenly distributed along the circumferential direction of the circular upper die base, the head of the cutter is provided with a cutting edge on the side close to the workpiece groove, and the cutting edge line of the cutting knife is inclined relative to the bottom surface of the upper die base. The inclination angle of the edge line relative to the bottom surface of the upper die base is 25 degrees. The lower side of the upper mold base is provided with a circular workpiece pressure plate 8, the workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com