A rib angle forming machine

A molding machine and reinforcement technology, which is applied in the direction of metal processing equipment, grinding machine parts, grinding feed movement, etc., can solve the problems of distortion, difficulty in processing reinforcement ribs, and broken reinforcement ribs, etc. The cycle shortens, the production is convenient and flexible, and the effect of reducing sliding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

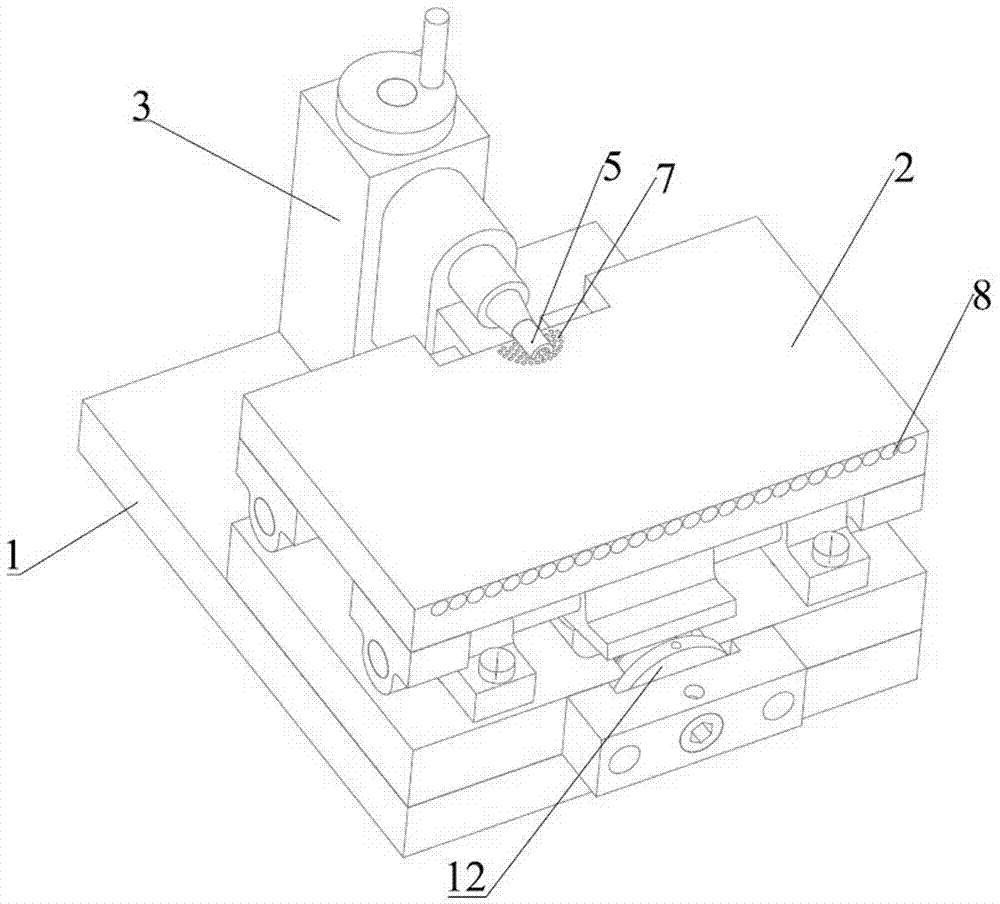

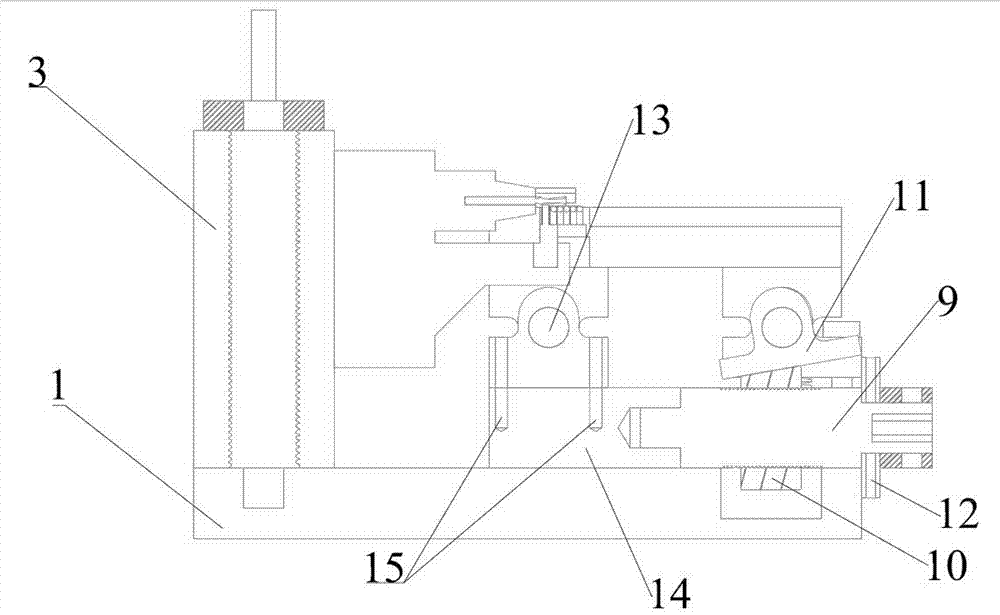

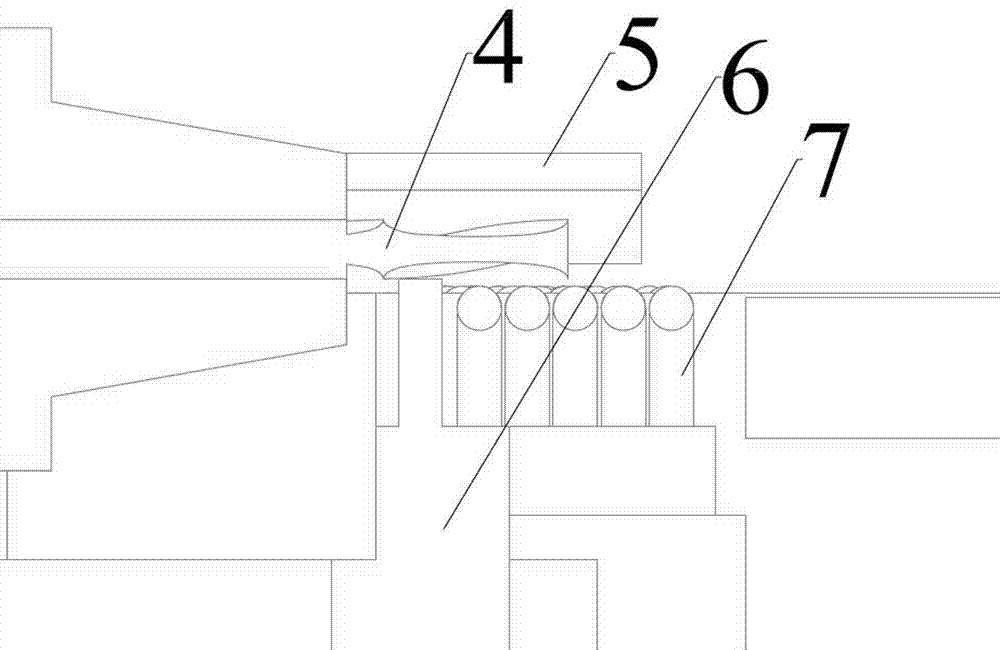

[0017] Such as figure 1 As shown, the edge of the workpiece is cut into a predetermined shape in advance, and then placed on the cutting table 2 for processing. Because one end of the bottom of the cutting table 2 is an angle adjustment module, and the other end is a fixed module, the angle adjustment module adjusts the height of one end of the cutting table 2, and the fixing module makes the cutting table 2 can only move vertically through the connecting rod 15, so after the interaction between the two , the table top of the cutting table 2 forms an angle with the horizontal plane. Adjust the rotating disc 12 for different rib angles. For ease of use, a dial is provided on the rotating disc 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com