An eighteen-high cold rolling mill emulsion injection device and its application

A technology of spraying device and emulsion, which is applied in the direction of workpiece cooling device, workpiece lubricating device, roll, etc., can solve the problems of poor lubrication and cooling effect of the roll gap and affect the surface quality of the strip steel, so as to improve the lubrication and cooling effect and improve the Effect of improving rolling speed and improving control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

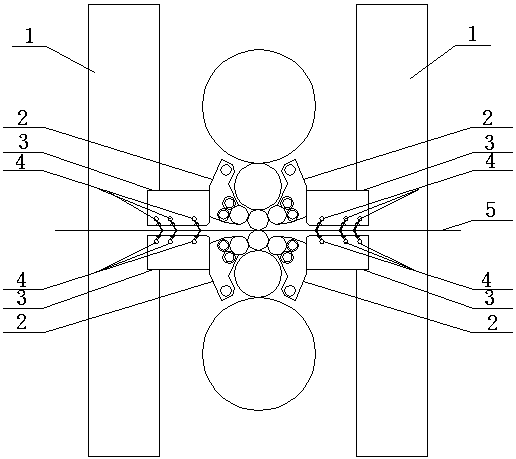

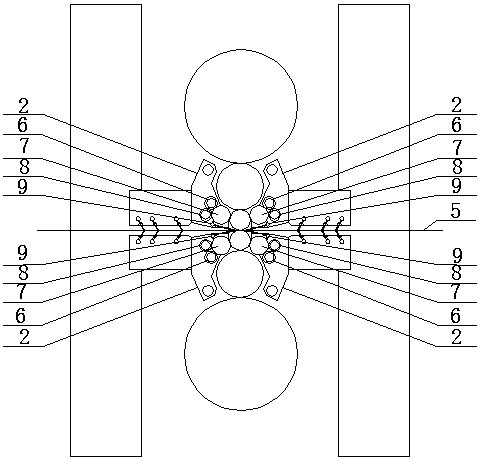

[0025] In order to overcome the problem that the effect of lubricating and cooling the roll gap in the existing eighteen-high cold rolling mill is not good, and the side support rolls cannot be cooled, which affects the surface quality of the strip, this embodiment provides a method such as figure 2 , image 3 The eighteen-high cold rolling mill emulsion injection device shown includes four side support frames 2 respectively arranged on four side support beams 3, and each side support frame 2 is provided with an upper backing bearing roll 6, a side Support rolls 7 and lower backing bearing rolls 8, and work rolls 18 arranged symmetrically up and down between the steel belt 5 between the side support frames 2, each side support frame 2 is close to the side support rolls 7 and the lower backing bearing rolls 8 position is provided with the second spraying device 9, and this second spraying device 9 comprises spraying beam 12 and several nozzles 10 and several nozzles 2 11 insta...

Embodiment 2

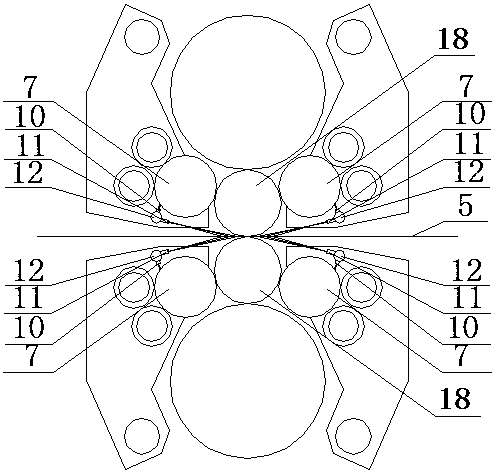

[0028] On the basis of embodiment 1, in order to make the emulsified liquid sprayed on the strip steel 5 and the side support roll 7 at the work roll nip place by the second injection device 9 more uniform, the lubricating and cooling effect is better, as image 3 and Figure 4 As shown, the spray beam 12 spans the side support frame 2, and the two ends of the spray beam 12 are fixed on the two ends of the side support frame 2, and the length direction of the spray beam 12 is parallel to the body of the side support roller 7. A number of nozzles 10 are distributed in a row on the injection beam 12, and a number of nozzles 11 are distributed in a row on the injection beam 12, and the angle between the nozzles 10 and 11 is 90°. The first nozzle 10 and the second nozzle 11 are alternately distributed on the spray beam 12, and the distance between every adjacent two nozzles 10 and every two adjacent nozzles 11 is 40-60 mm. The included angle between the nozzle two 11 and the leng...

Embodiment 3

[0030] On the basis of the above examples, if Figure 4 As shown, the present embodiment provides an application of an eighteen-high cold rolling mill emulsion injection device. The injection beam 12 is a hollow cylinder structure with one end open and the other end closed. The outer diameter of the hollow cylinder is 30mm. The inner diameter is 20mm, and one end of the opening of the spray beam 12 on each side support frame 2 is connected to the emulsion pipeline 15, and the emulsion pipeline 15 is provided with a flow control valve 13, a flow sensor 14, a pressure control valve 16 and a pressure The sensor 17 controls the emulsion flow rate flowing into each injection beam 12 through the flow control valve 13 and the flow sensor 14, and the pressure control valve 16 and the pressure sensor 17 control the injection pressure of nozzle one 10 and nozzle two 11 on each injection beam 12 .

[0031] Wherein, the flow rate of the injection beam 12 on each side support frame 2 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com