Nanofluid MQL and Atomization Cooling Ultra-Precision Cutting Medium Supply System

A nano-fluid, micro-lubrication technology, used in grinding/polishing equipment, grinding/polishing safety devices, metal processing equipment, etc. Crack lubrication and other problems, to avoid the rupture of lubricating oil film and lubrication failure, avoid excessive heat generation, and improve the lubrication state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

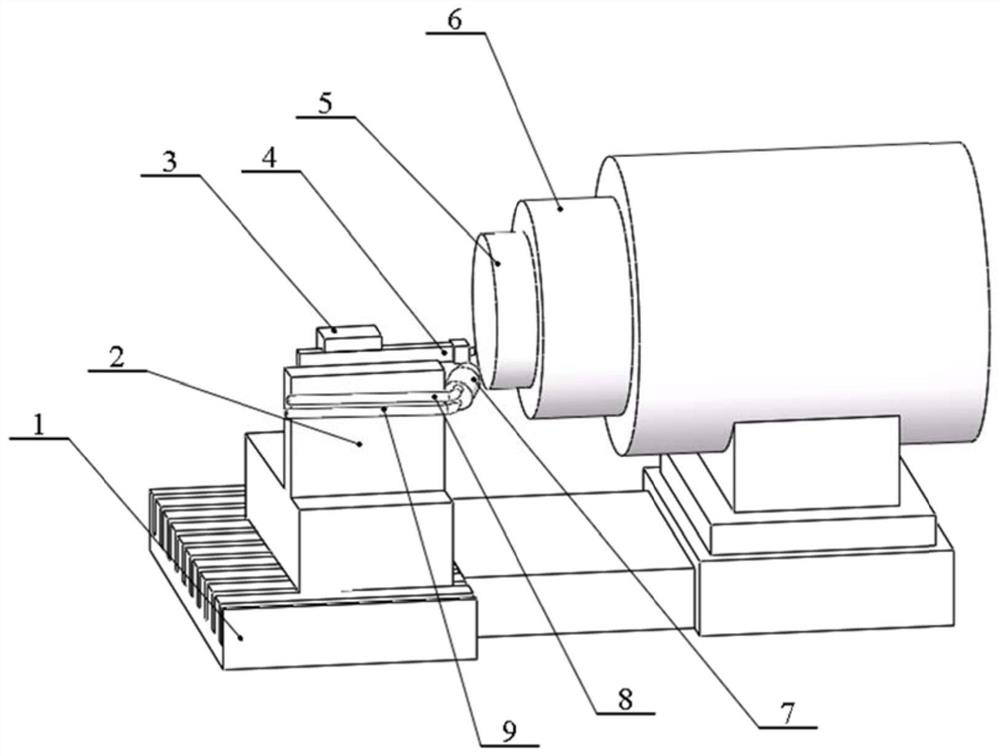

[0079] The application provides a nanofluid micro-lubrication and atomization cooling ultra-precision cutting medium supply system, including: a workbench 1, a compressed air gas path 9, a nanofluid liquid path 8, a tool 4, a workpiece to be processed 5, and jet atomization Nozzle 7; tool 4 and workpiece 5 to be processed are arranged on the worktable 1, and move toward or away from each other; the jet atomization nozzle 7 is arranged on one side of the tool 4, and the second end of the jet atomization nozzle 7 faces the tool 4 and the The cutting area contacted by the workpiece 5 to be processed is set; the worktable 1 used in the present application and this embodiment can be a commonly used worktable. The specific structure is not exhaustive.

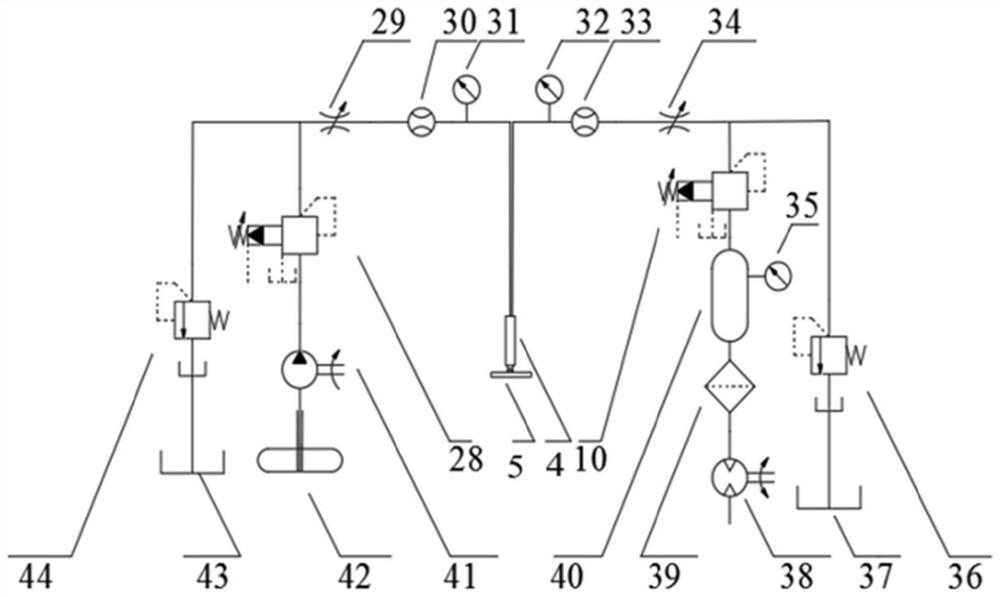

[0080] The compressed air gas path 9 and the nano-fluid liquid path 8 are respectively connected to the first end of the jet atomization nozzle 7 for feeding;

[0081] The second end of the jet atomizing nozzle 7 sprays a three-phas...

Embodiment 2

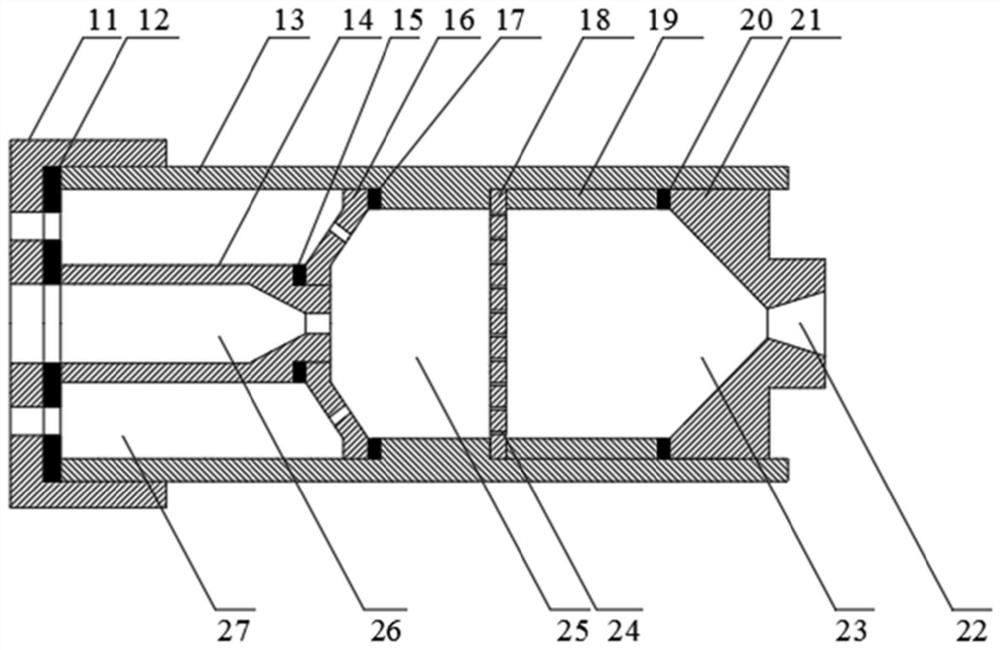

[0109] The difference between the spray head 21 used in this embodiment and Embodiment 1: as Figure 4 As shown in a, the included angle c shown in Fig. a is the included angle between the inner side wall of the nozzle outlet 22 and the extension line of the feed aperture, and the included angle c is defined the same in other embodiments; the cross-section of the acceleration section 23 used in this embodiment is the same. It is a trapezoid; the included angle c in the cross section of the nozzle outlet 22 is 10~15°.

[0110] Other differences between this embodiment and Embodiment 1: the angle between the extension line of the central axis of the jet atomizing nozzle 7 and the machining end face of the workpiece 5 to be machined is β, and the angle of β is 35°; the spray end face of the jet atomizing nozzle 7 and the tool 4. The distance d between the cutting tip and the contact point of the workpiece 5 to be processed is 5 cm; the jet flow rate of the jet atomizing nozzle 7 ...

Embodiment 3

[0112] The difference between the spray head 21 used in this embodiment and Embodiment 1: as Figure 4 As shown in b, the cross-section of the acceleration section 23 is a trapezoid, and the bottom surface of the trapezoid is provided with a connecting structure with a rectangular cross-section; the included angle c is 15-30°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com