Solid waste treatment device and method

A solid waste and treatment device technology, applied in solid separation, chemical instruments and methods, magnetic separation, etc., can solve the problems of easy air pollution, large investment and high cost of incineration, and reduce labor intensity and resource area. , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

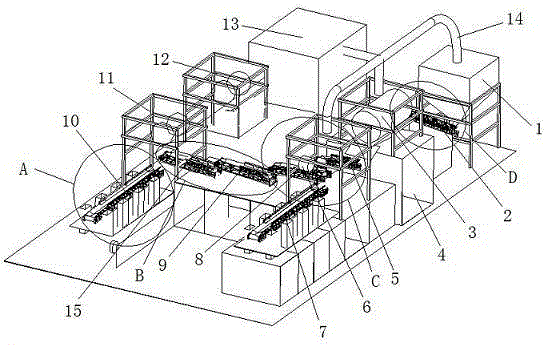

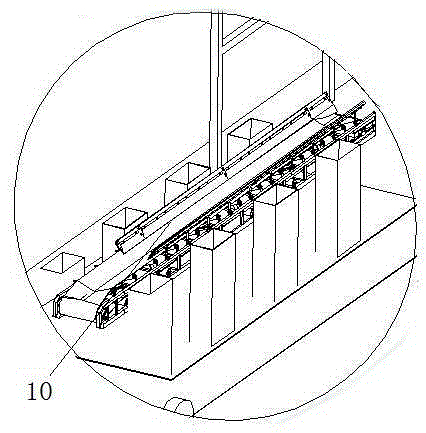

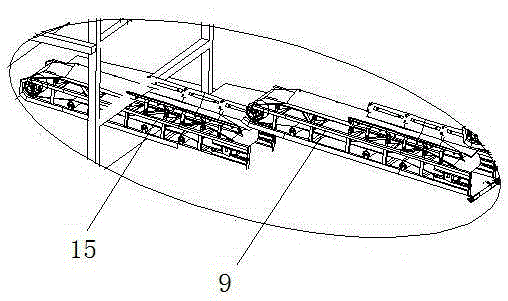

[0030] Such as figure 1 , 2 , 3, 4 and 5 shown in a solid waste treatment device, including sequentially arranged silo 1, the first conveying equipment 2, trommel 3, magnetic separator 5, eddy current magnetic separator and electromagnetic separator 12. The eddy current magnetic separator includes a first stage eddy current magnetic separator 8 and a second stage eddy current magnetic separator 8 . Sorting is carried out by a two-stage eddy current magnetic separator, and the scrap iron with impurities, that is, slag iron, is sorted out. The discharge port of the silo 1 is connected with the feed port of the trommel 3 through the first conveying equipment 2; it also includes an air magnetic separator 6, a gravity air separator 11 and an eddy current separator 15, the wind magnetic separator 11 and the eddy current separator 15. The magnetic separator 6 is connected with the magnetic separator 5 . A vibrating feeder is provided below the silo 1, and the vibrating feeder can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com