Physical concentration and phosphorus reduction method for skarn-type high-phosphorus molybdenum ore

A skarn-type, high-phosphorus-molybdenum technology, applied in chemical instruments and methods, flotation, wet separation, etc., can solve problems such as high cost and loss of molybdenum metal, and achieve improved grade, reduced coverage and wrapping, and reduced Effect of Phosphorus Grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

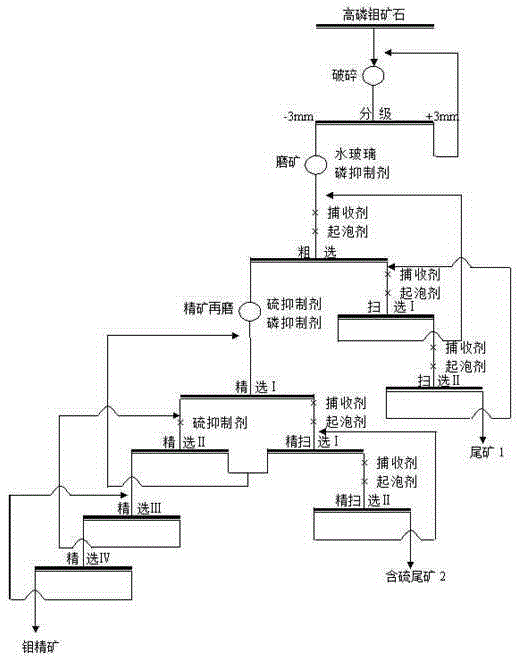

[0035] With Mo content being 0.13%, the phosphorus-molybdenum ore of P content 0.12% is raw material, utilizes technology of the present invention, carries out following steps, as figure 1 :

[0036] (1) Crushing: The raw ore is crushed and screened by a crusher, and the raw ore with a particle size of +3mm is returned for crushing until the particle size of all the raw ore reaches the -3mm level.

[0037] (2) Grinding: For the crushed -3mm raw ore, use a rod mill or a ball mill for closed-circuit grinding. At the same time, 600g / t of inhibitor water glass and 400g / t of sodium hexametaphosphate were added to the mill, and the raw ore was ground to -0.075mm content of 61.0%.

[0038] (3) Flotation roughing operation: For the raw ore sample that has been ground, firstly stir and adjust the slurry to control the concentration of the slurry to 35%, and then add kerosene 240g / t, 2 # The oil is 60g / t, and the roughing operation is carried out in the flotation machine. The operati...

Embodiment 2

[0044] Be that 0.12% with Mo content, the phosphorus-molybdenum ore of P content 0.18% is raw material, utilize technology of the present invention, carry out following steps, as figure 1 :

[0045] (1) Crushing: The raw ore is crushed and screened by a crusher, and the raw ore with a particle size of +3mm is returned for crushing until the particle size of all the raw ore reaches the -3mm level.

[0046] (2) Grinding: For the crushed -3mm raw ore, use a rod mill or a ball mill for closed-circuit grinding operations, and at the same time add 800g / t of water glass, low molecular weight acrylic acid and maleic anhydride to the mill. The copolymer is 400g / t, and the raw ore is ground to -0.075mm with a content of 71.5%.

[0047] (3) Flotation roughing operation: For the raw ore sample that has been ground, firstly stir and adjust the slurry to control the concentration of the slurry to 31%, and then add kerosene 280g / t, 2 # The oil is 70g / t, and the roughing operation is carrie...

Embodiment 3

[0053] Be that 0.14% with Mo content, the phosphorus-molybdenum ore of P content 0.17% is raw material, utilize technology of the present invention, carry out following steps, as figure 1 :

[0054] (1) Crushing: The raw ore is crushed and screened by a crusher, and the raw ore with a particle size of +3mm is returned for crushing until the particle size of all the raw ore reaches the -3mm level.

[0055] (2) Grinding: For the crushed -3mm raw ore, use a rod mill or a ball mill for closed-circuit grinding operations. At the same time, add 700g / t of water glass and 500g / t of low molecular weight sodium polyacrylate to the mill to grind the raw ore To -0.075mm content 73.8%.

[0056] (3) Flotation roughing operation: For the raw ore sample that has been ground, firstly stir and adjust the slurry to control the concentration of the slurry to 34%, and then add kerosene 360g / t, 2 # The oil is 80g / t, and the roughing operation is carried out in the flotation machine. The operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com