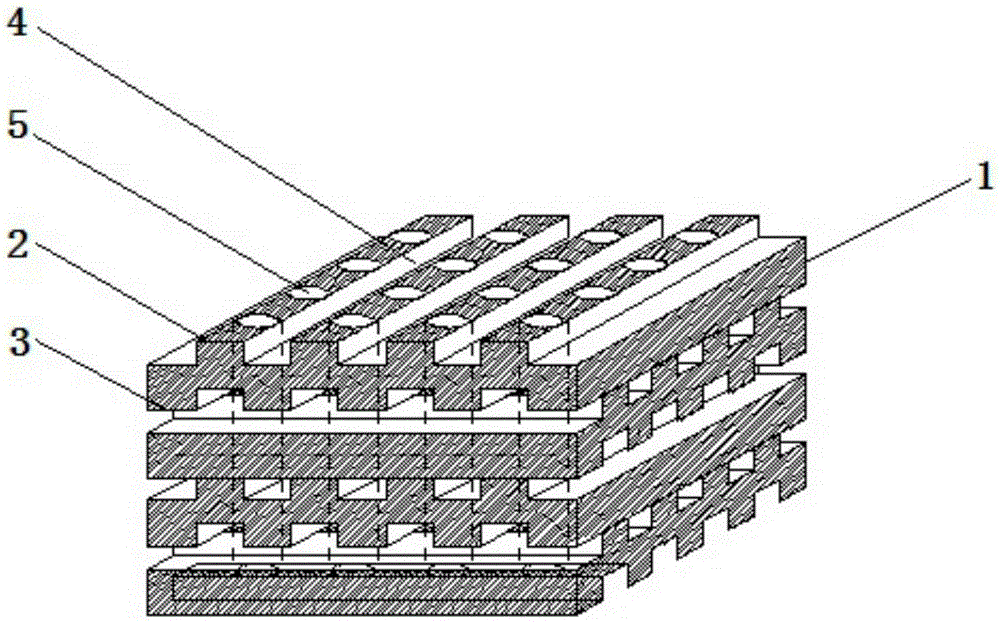

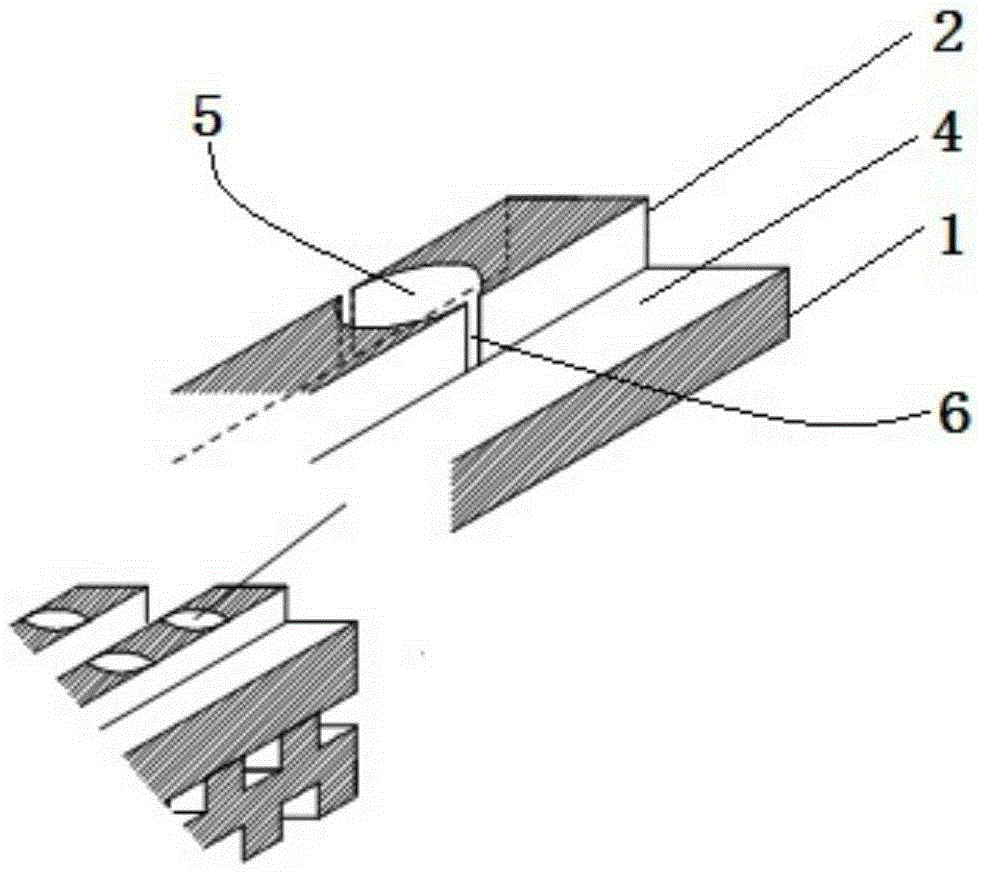

Bone repair material with multi-dimensional channel structure

A channel structure and bone repair technology, applied in the field of biomedical materials, can solve the problems of poor pore permeability, small pore size, and low mechanical properties of artificial bone repair materials, and achieve good mechanical transmission, high strength, and good structural stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Bone repair material preparation

[0060] Step 1 Prepare the base material

[0061] Weigh 50g of mineralized collagen material (water content is 80%), add ceramic powder 2g therein, stir clockwise with the rotating speed of 100rpm, adjust the pH value to 7.0 with 1.0M phosphoric acid solution and 1.0M sodium hydroxide lye, Then adjust the pH value to 7.2 with 0.5M sodium carbonate solution, and the conductivity is 1.5ms / cm. Stand still for 30 minutes, then centrifuge at 10000rpm at 4°C for 30 minutes to remove the supernatant. Add Staphylococcus aureus fermentation liquid filtrate to the precipitation, make the coagulation enzyme activity be 1600 μ g / g, add 37.5g collagen material (the purity of collagen is 40mg / g), continue to stir uniformly in the same direction, and adjust the precipitation to make the composite mineral The pH value of the collagen matrix is 7.2, and the conductivity is 3.0ms / cm. At greater than 1.01×10 2 Degas under Pa vacuum conditions, and t...

Embodiment 2

[0074] Step 1 Prepare the base material

[0075] Weigh 65g mineralized collagen material (water content is 80%), add ceramic powder 2g therein, stir clockwise with the rotating speed of 100rpm, then adjust the pH value to 7.0 with 1.0M phosphoric acid solution and 1.0M sodium hydroxide lye , and then adjust the pH value to 7.2 with 0.5M sodium carbonate solution, and the conductivity is 1.5ms / cm. Stand still for 30 minutes, then centrifuge at 10000rpm at 4°C for 30 minutes to remove the supernatant. Add Staphylococcus aureus fermentation liquid filtrate to the precipitate to make the coagulase activity 3200 μg / g, add 75g of collagen material (the purity of collagen is 40mg / g), continue to stir evenly in the same direction, and adjust the precipitate to make the composite mineralization The pH of the collagen matrix is 7.2 and the conductivity is 3.0ms / cm. At greater than 1.01×10 2 Degas under Pa vacuum conditions, and then continue to use 1.0M phosphoric acid solution and...

Embodiment 3

[0088] Step 1 Prepare the base material

[0089] Take by weighing 50g mineralized collagen material (water content is 80%), add ceramic powder 1g wherein, stir clockwise with the rotating speed of 100rpm, then adjust the pH value to 7.0, then adjust the pH value to 7.2 with 0.5M sodium carbonate solution, and the conductivity is 1.5ms / cm. Stand still for 30 minutes, then centrifuge at 10000rpm at 4°C for 30 minutes to remove the supernatant. Add Staphylococcus aureus fermentation liquid filtrate to the precipitate to make the coagulase activity 1600 μg / g, add 75g of collagen material (the purity of collagen is 40mg / g), continue to stir evenly in the same direction, and adjust the precipitate to make the complex mineralization The pH of the collagen matrix is 7.2 and the conductivity is 3.0ms / cm. At greater than 1.01×10 2 Degas under Pa vacuum conditions, and then continue to adjust with 1.0M phosphoric acid solution and 1.0M sodium hydroxide lye solution to make the condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com