Tooth arrangement method for manufacturing complete dentures

A complete denture and tooth technology, applied in dentistry, dentures, dental prosthesis, etc., can solve the problems of complete denture design deviation and insufficient degree of personalization, and achieve the effect of meeting clinical needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0085] The tooth arrangement method for making a complete denture of this embodiment includes the following steps:

[0086] 1. The establishment of a three-dimensional database based on parametric complete denture artificial teeth. This step includes: extraction of tooth feature information and marking of tooth feature points.

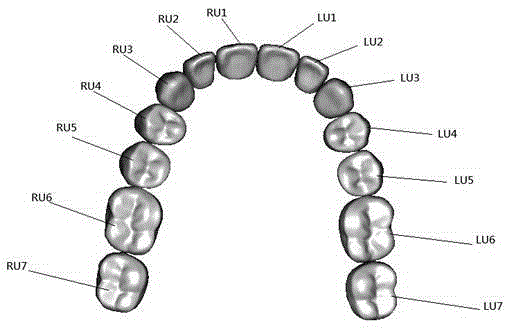

[0087] (1) Extraction of artificial standard tooth feature information

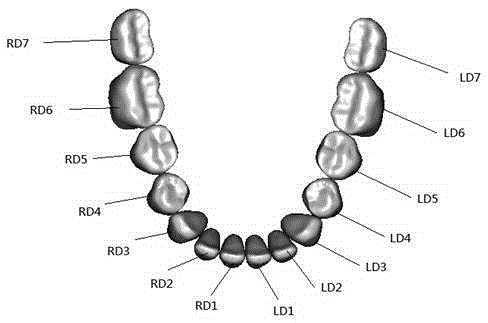

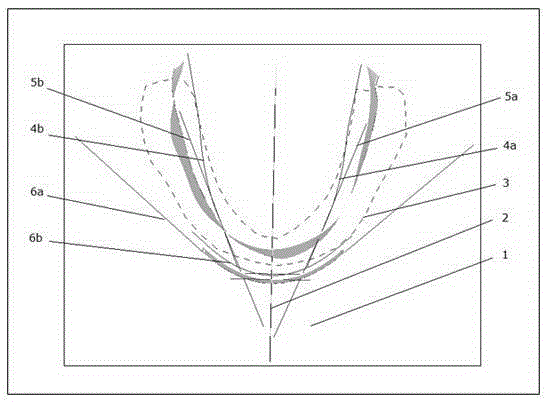

[0088] Such as Figure 1a with Figure 1b As shown, a set of artificial teeth is composed of 28 standard teeth. The shapes of teeth in different positions are different, and each tooth is very irregular. To arrange teeth reasonably, we must first obtain the characteristic information of each tooth. The invention inputs the three-dimensional model of the standard tooth, selects the characteristic information on each tooth by interactive picking, and establishes the local coordinate system of the tooth, so as to control the posture and position of the local coordinate system. The feature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com