Carbon fiber negative-ion transmitting end assembly

A negative ion emission and carbon fiber technology, applied in the direction of electrical components, etc., can solve the problems of affecting the effect of negative ions, mutual pollution of the emitter head, loose solder, etc., and achieve the effect of eliminating mutual pollution, simple structure and firm welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

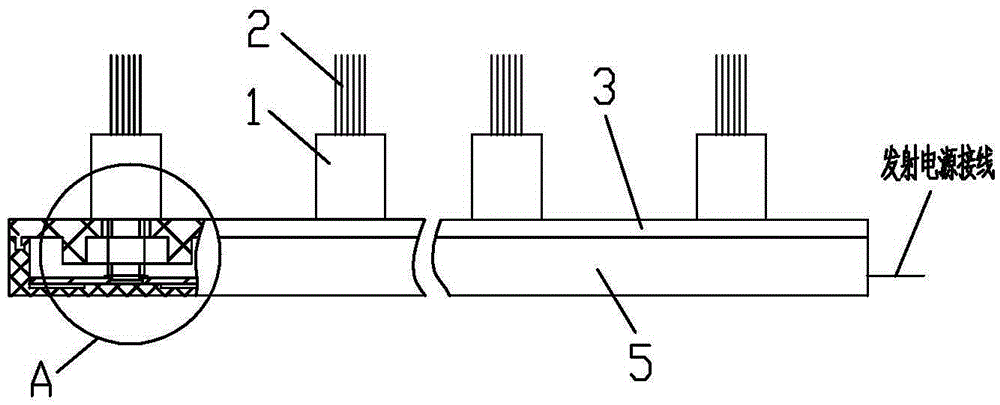

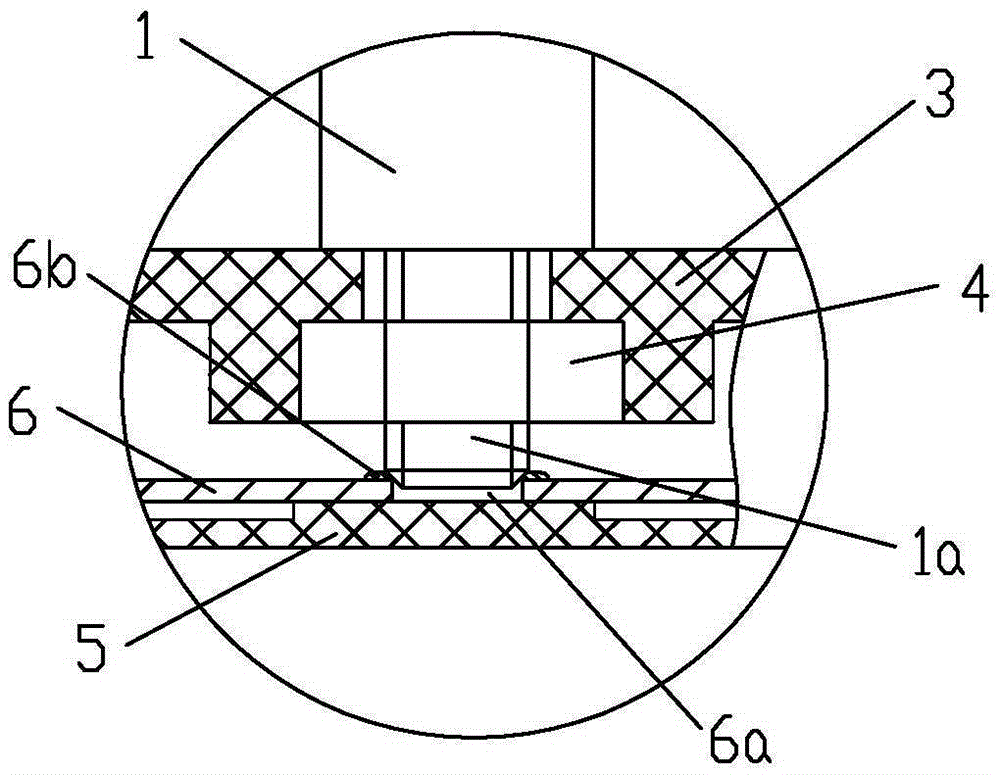

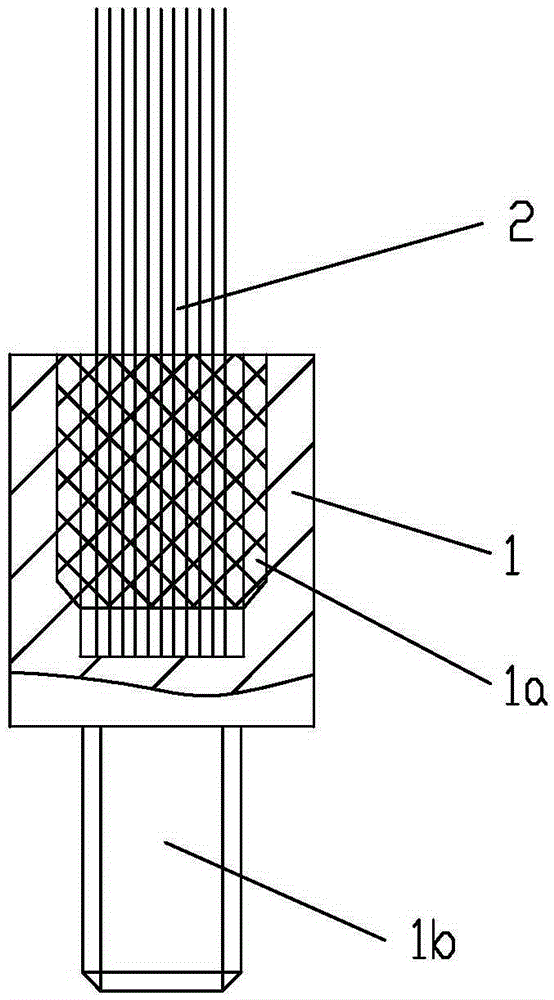

[0017] see figure 1 , figure 2 , image 3 , a carbon fiber negative ion emitter assembly, including a plurality of emitters, the plurality of emitters are arranged in rows on the base bar 3, the base bar 3 is fitted with a nut 4, and the base bar 3 is buckled and connected to the bottom box 5 The launch head includes a metal head 1, the metal head 1 has a two-stage structure, the front section of the metal head 1 is inserted with a carbon fiber bundle 2 through the jack 1a, and is fixed by soldering, and the metal head 1 is connected to the nut through the rear screw part 1b 4 is fixedly connected; the bottom box 5 is provided with a busbar 6, and the busbar 6 abuts against the distal end of the screw part 1b of the metal head 1.

[0018] Wherein, the socket 1a is a blind hole, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com