A kind of preparation method of sulfur-containing electrode material

An electrode material and sulfur element technology, which is applied in the field of preparation of sulfur-containing electrode materials, can solve the problems of poor battery safety, reduced sulfur content, pierced separator, etc., and achieves the effects of large capacity, high sulfur content and strong adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

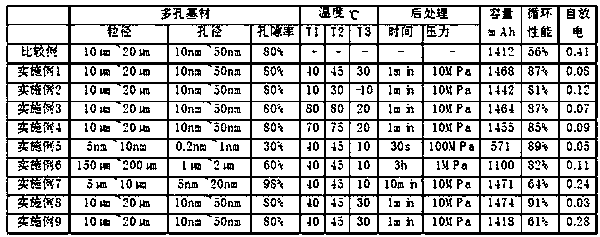

Examples

Embodiment 1

[0025] Embodiment 1, differs from comparative example in that this embodiment comprises the following steps:

[0026] Preparation of sulfur-containing precursor: at 40°C, uniformly mix sulfur element and carbon disulfide to obtain a saturated solution of sulfur carbon disulfide for use;

[0027] Sulfur-containing solution filling: choose a porous carbon material with a particle size of 10μm~20μm, a pore size of 10nm~50nm, and a porosity of 80% as the substrate; fully mix the above solution with the porous carbon substrate in an environment of 45°C, so that the solution Constantly infiltrate and immerse into the pore structure of the substrate; then apply 10MPa nitrogen pressure to the material, hold the pressure for 1min, and obtain a material in which the pore structure of the porous substrate is completely filled with the solution;

[0028] Loading of sulfur-containing components: Cool the material filled with the solution to 30°C, and apply ultrasonic treatment to the mater...

Embodiment 2

[0031] Embodiment 2, different from Embodiment 1, this embodiment includes the following steps:

[0032] Preparation of sulfur-containing precursor: at 10°C, uniformly mix sulfur element and carbon disulfide to obtain a saturated solution of sulfur carbon disulfide for use;

[0033] Sulfur-containing solution filling: choose a porous carbon material with a particle size of 10μm~20μm, a pore size of 10nm~50nm, and a porosity of 80% as the substrate; fully mix the above solution with the porous carbon substrate in an environment of 30°C, so that the solution Continuously infiltrate and immerse into the pore structure of the substrate; then apply 10MPa nitrogen pressure to the material, hold the pressure for 1min, and obtain the pore structure of the porous substrate is completely filled with the solution;

[0034] Sulfur-containing component loading: Cool the material filled with the solution to -10°C, and apply ultrasonic treatment to the material at the same time, so that the ...

Embodiment 3

[0037] Embodiment 3, different from Embodiment 1, this embodiment includes the following steps:

[0038] Preparation of sulfur-containing precursor: at 80°C, mix the sulfur element and benzene evenly to obtain a benzene saturated solution of sulfur for use;

[0039] Sulfur-containing solution filling: choose a porous carbon material with a particle size of 10μm~20μm, a pore size of 10nm~50nm, and a porosity of 80% as the substrate; fully mix the above solution with the porous carbon substrate in an environment of 80°C, so that the solution Continuously infiltrate and immerse into the pore structure of the substrate; then apply 10MPa nitrogen pressure to the material, hold the pressure for 1min, and obtain the pore structure of the porous substrate is completely filled with the solution;

[0040] Sulfur-containing component loading: Cool the material filled with the solution to 20°C, and apply ultrasonic treatment to the material at the same time, so that the sulfur-containing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com