A flame stabilizer for a recirculation combustor

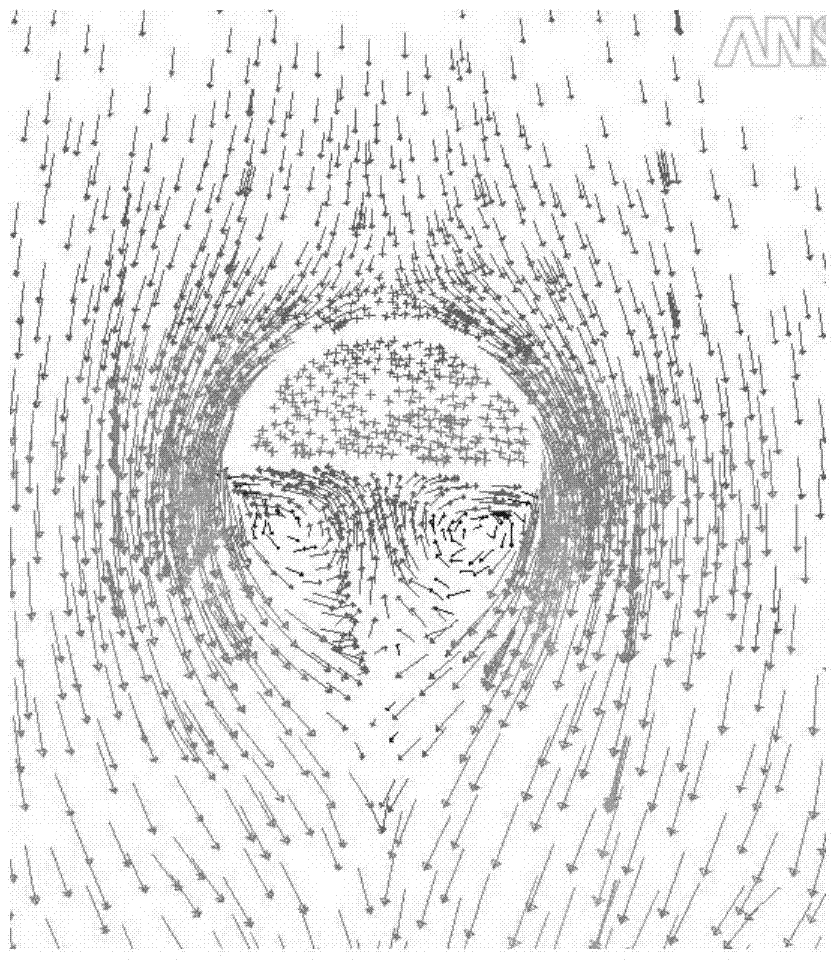

A technology of flame stabilizer and recirculation combustion chamber, which is applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of wasting manpower and material resources, increasing the research and development cost of combustion chamber, and combustion instability, etc., to reduce production cost, expanding the lean flameout boundary, and the effect of a strong flame stabilization vortex system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

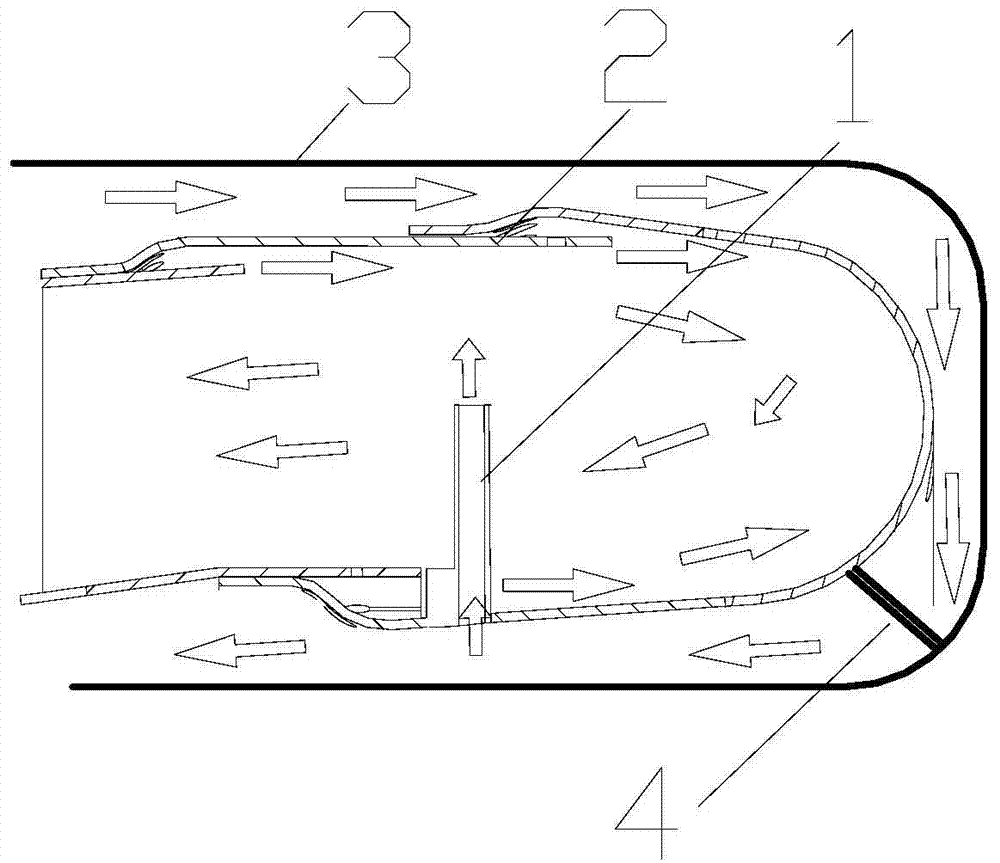

[0020] In order to solve the problems of the prior art, the present invention provides a flame stabilizer for a reflux combustion chamber. The flame stabilizer is installed in the head area of the reflux combustion chamber, such as figure 1 As shown, 12 flame stabilizers 1 are connected to the flame tube 2 at the bottom by welding, the flange 4 is welded to the head wall of the flame tube 2, and the flame tube 2 is bolted to the combustion chamber machine through the other end of the flange 4 The end face of box 3;

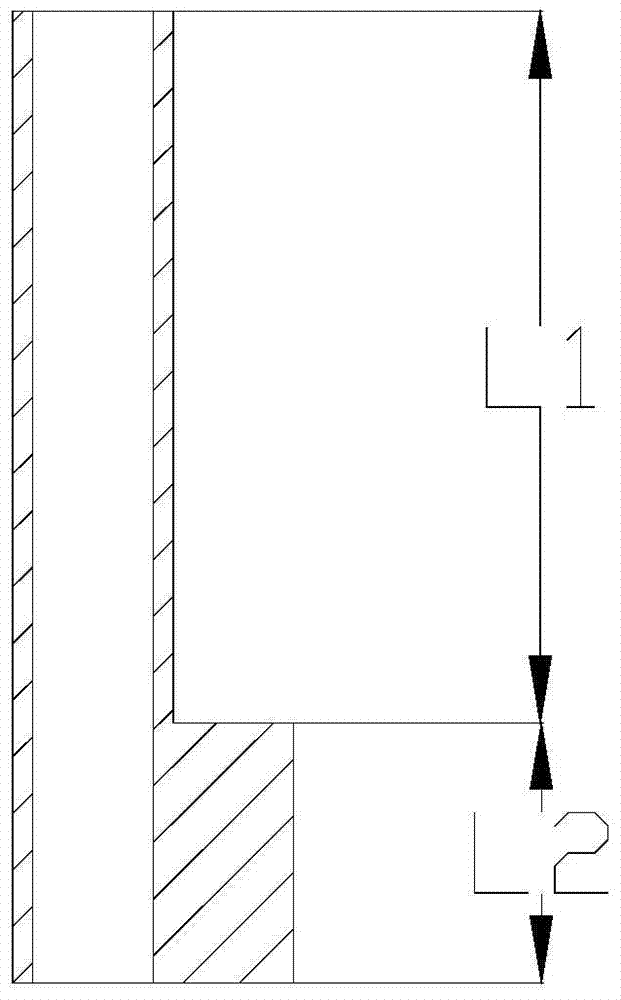

[0021] The flame stabilizer 1 is an integral two-stage body, which is divided into upper and lower sections. The upper section, that is, the L1 section is hollow, and the cross-sectional shape is a semicircular arc ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com