Plastic tube

A technology of plastic pipes and connecting pipes, which is applied in the field of plastic pipes, can solve the problems of short service life and low degree of automation, and achieve the effects of long service life, simple structure and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

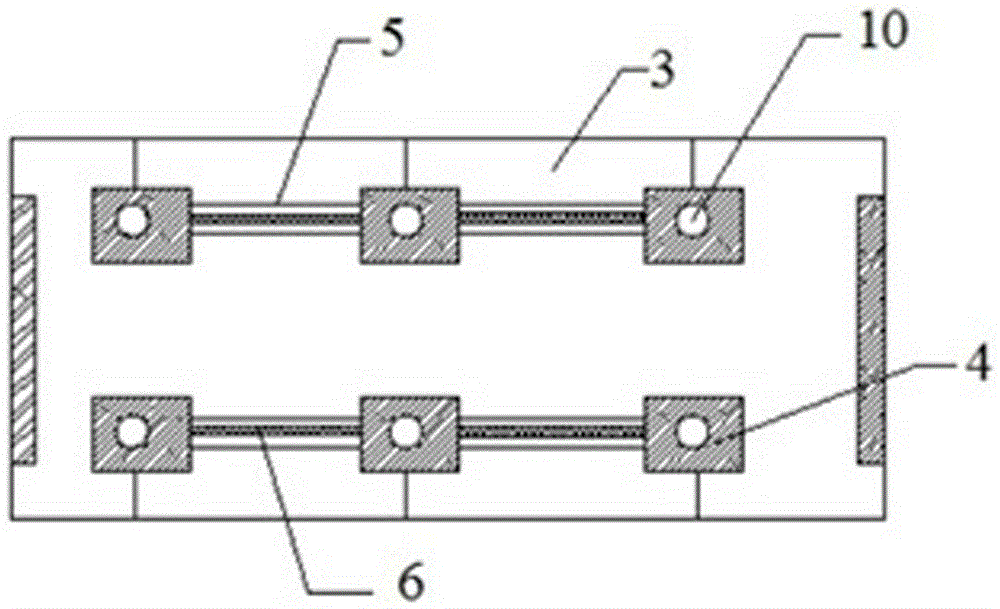

[0014] figure 1 A specific embodiment of the present invention is shown: a plastic tube comprising a plastic tube 1 and a memory layer 2. The material of the plastic tube 1 is a polyethylene grafted carbon black masterbatch composite material, and the memory layer 2 is a chip layer, The chip layer is composed of a polyethylene coating layer 3 and a chip 4 embedded on the coating layer. The chip 4 and the chip 4 are connected through a connecting tube 5 and a data line 6, and the data line 6 is built in the connection Inside the tube 5.

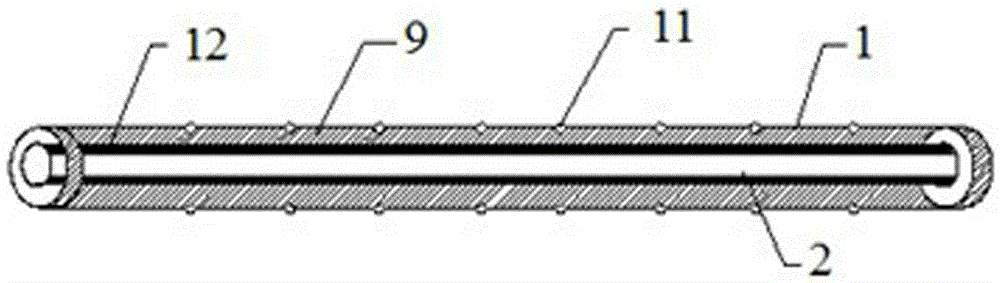

[0015] In addition, such as figure 2 As shown, the outer side of the plastic tube 1 is provided with a heat preservation layer 9, the chip 4 is provided with a timing detection device 10, and the outer side of the heat preservation layer 9 is provided with small LED lamp beads 11, the small LED lamp beads 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com