Construction method of separate sleepers and sleepers for the follow-up trolley and battery car system of the portable shield machine

A construction method and battery car technology are applied in the field of sleeper sleeper construction for the follow-up trolley of the portable shield machine and the battery car system, which can solve the problems of heavy weight, multi-manpower, and long time consumption of a single sleeper, so as to reduce labor intensity and reduce sleepers. Weight, the effect of reducing steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

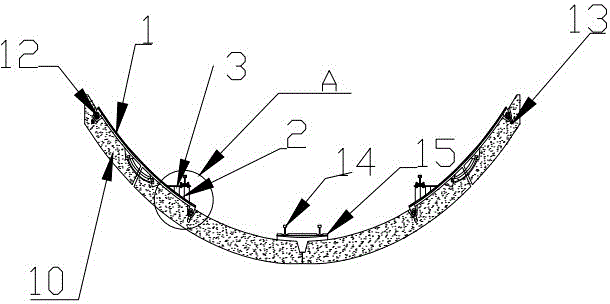

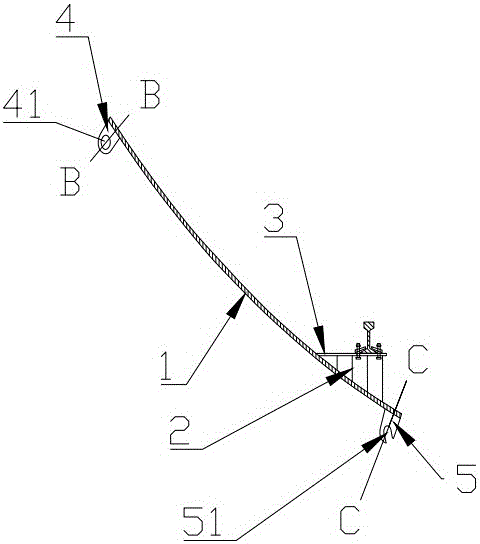

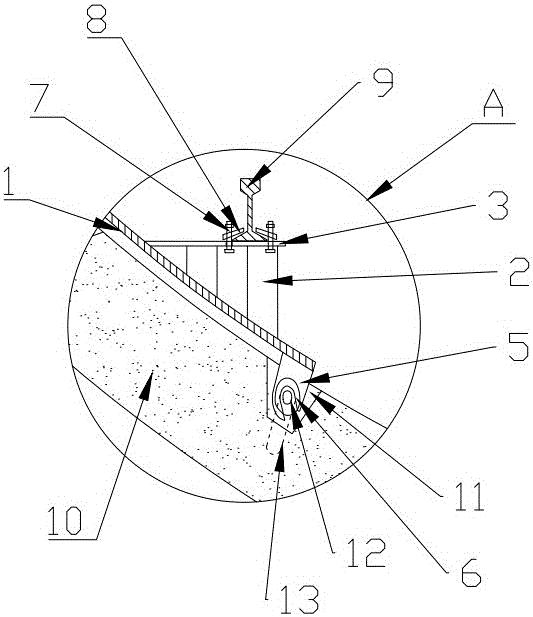

[0038]As shown in the figure, a method for constructing separate sleepers and sleepers for the follow-up trolley and battery car system of a portable shield machine involves the shield segment 10 used to install the trolley sleeper and the battery car sleeper and the tubes on the shield segment 10 The hand holes 11 of the bent bolts connected by the annular seam of the segments and the head 12 of the bent bolts connected by the annular joints of the segments; The two ends of the arc-shaped steel plate 1 are welded with the upper limit ear plate 4 and the lower limit ear plate 5 matching the bent bolt hand hole 11 connected to the circular seam of the segment, and the upper limit ear plate 4 and the lower limit ear plate 5 It is sleeved on the bent bolt wire head 12 connected by the ring seam of the segment, and is detachably connected by the nut 6; the arc-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com