Integrated dehydrating drying machine for parts

A technology for dehydration and drying of components, applied in the direction of electrolysis components, cells, electrolysis process, etc., can solve the problems of high labor intensity, cumbersome loading and unloading process, high processing cost, etc., to save labor, good sealing effect, and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments and description of the accompanying drawings:

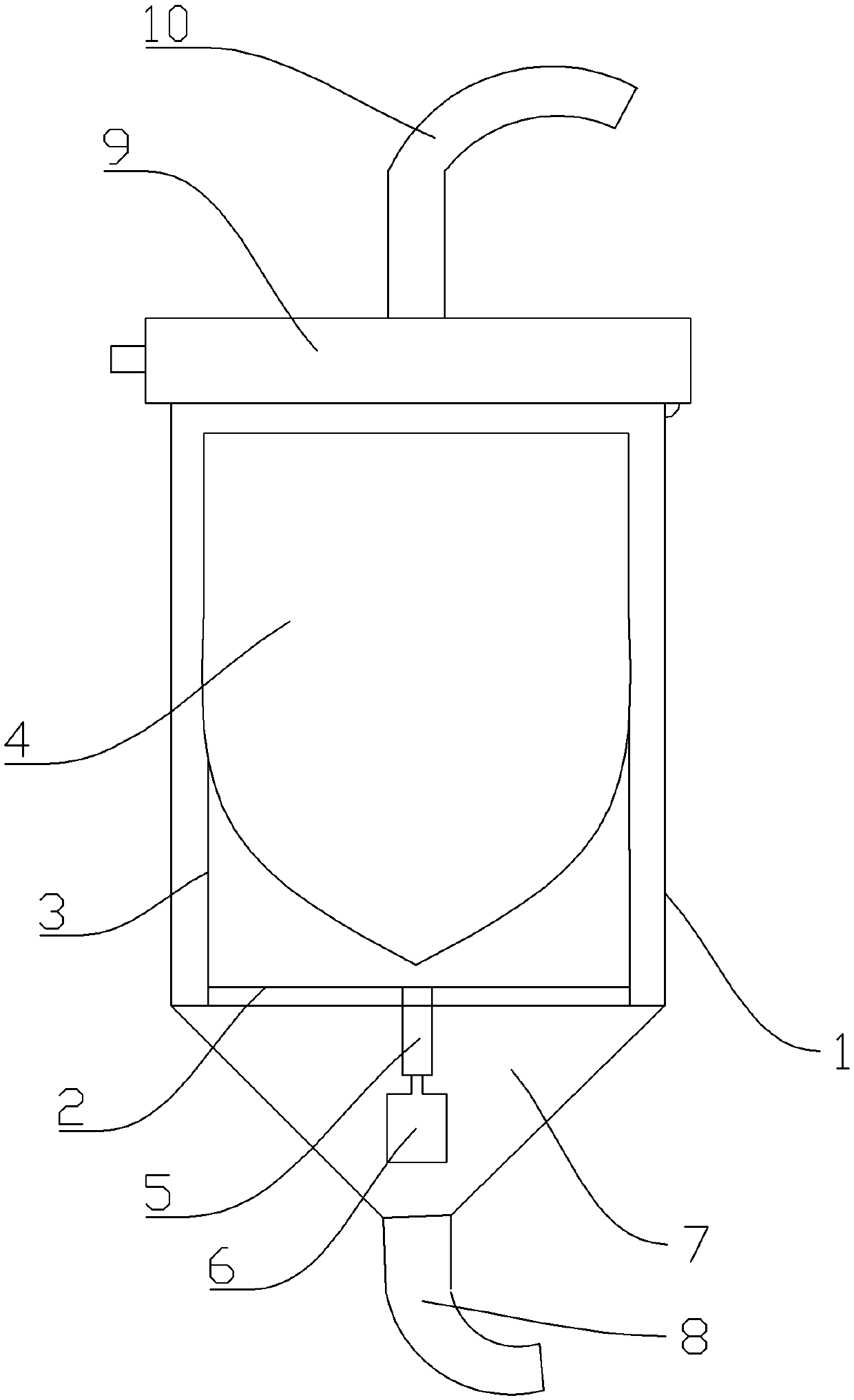

[0012] The reference numerals in the accompanying drawings of the description include: casing 1, turntable 2, mounting frame 3, parts cylinder 4, rotating shaft 5, motor 6, water collecting tank 7, drain pipe 8, cylinder cover 9, and hot air pipe 10.

[0013] The embodiment is basically as attached figure 1 As shown: the casing 1 includes a dehydration mechanism and a drying mechanism. The dehydration mechanism includes a turntable 2 installed at the bottom of the casing 1. A mounting frame 3 is fixed on the turntable 2. The mounting frame 3 is in the shape of a circular arc protrusion. The mounting frame 3 A reticulated part tube 4 is placed inside, the bottom of the part tube 4 is conical, and the conical bottom of the part tube 4 is stuck in the mounting frame 3 . A drainage cavity is formed between the outer wall of the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com