A kind of chute liner of ironmaking blast furnace distributor and its preparation method

A technology for ironmaking blast furnaces and distributors, which is applied in the field of chute liners and can solve problems such as short life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

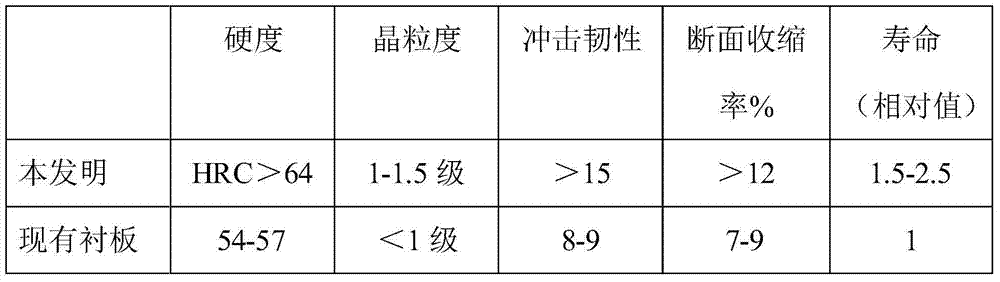

Examples

Embodiment 1

[0037] An ironmaking blast furnace distributor chute liner, the chemical composition of the chute liner includes: by weight percentage, C 3.5%, Mn 0.65%, Si 0.45%, P 0.035%, S 0.035%, W 3.55% , Mo 1.85%, V0.85%, Cr 19.5%, B 0.65%, and the balance is Fe.

Embodiment 2

[0039] An ironmaking blast furnace distributor chute liner, the chemical composition of the chute liner includes: by weight percentage, C 3.6%, Mn 0.75%, Si 0.67%, P 0.045%, S 0.04%, W 4.2% , Mo 2%, V 1%, Cr19.8%, B 0.7%, and the balance is Fe.

Embodiment 3

[0041] An ironmaking blast furnace distributor chute liner, the chemical composition of the chute liner includes: by weight percentage, C 3.2%, Mn 0.7%, Si 0.5%, P 0.04%, S 0.03%, W 3.5% , Mo 1.9%, V 0.9%, Cr 20%, B 0.7%, and the balance is Fe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com