Compound microorganism humic acid fertilizer special for organic cultivation and preparation method thereof

A technology of compound microorganisms and special fertilizers, which is applied in the preparation of organic fertilizers, the treatment of biological organic parts, organic fertilizers, etc., can solve the problems of long fermentation period, single type of bacteria, and incomplete self-supply of raw materials, etc., and achieve short fermentation period , soil ecosystem improvement, and the effect of reducing soil compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

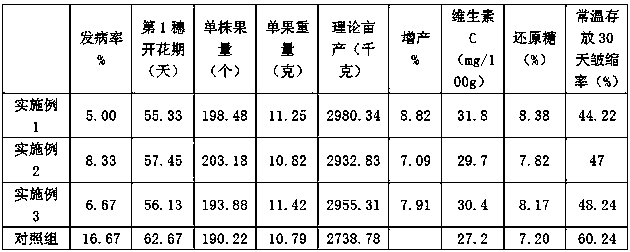

Examples

Embodiment 1

[0021] (1) Preparation of composite microbial strains: The mass percentages were 60% of chaff, 20% of wheat bran, and 20% of corn flour, and mixed evenly in proportion. The main ingredients are fully mixed, first aerobic fermentation for 7 days, and then anaerobic continuous fermentation for 7 days, dried at low temperature, moisture content ≤ 12%, bagged and sealed for storage.

[0022] (2) Pre-fermentation: Add the inoculum of 1.5% of the compound microbial strains described in step (1) into the organic fertilizer raw material, mix evenly, pile up to a height of 1.5 meters and supply oxygen for 8 days, during which time the pile is turned over every day deal with. Organic fertilizer raw materials and their corresponding mass percentages are: crop straw 30%, poultry manure 15%, animal and plant residues (including kitchen waste, crop residues, etc.) 30%, peanut bran 8%, pond mud 10%, urea 0.5%, shell powder 3%, magnesium sulfate 0.5%, slaked lime 2.5%, zeolite powder 0.5%. ...

Embodiment 2

[0025] (1) Preparation of composite microbial strains: The mass percentages were 50% of chaff, 35% of wheat bran, and 15% of corn flour, and mixed evenly in proportion, and the mixed bacterial liquid was mixed with the culture medium at an inoculum of 5% by mass. The main ingredients are fully mixed, first aerobic fermentation for 10 days, then anaerobic continuous fermentation for 10 days, low-temperature drying, moisture content ≤ 12%, bagged and sealed for storage.

[0026] (2) Pre-fermentation: Add the compound microbial strains described in step (1) into the organic fertilizer raw material with an inoculum amount of 1% by mass, mix and evenly pile up to a height of 2 meters, supply oxygen and ferment for 10 days, and turn the pile every day during the period . Organic fertilizer raw materials and their corresponding mass percentages are: 14% of rice husk, 14% of crop straw, 20% of livestock manure, 25% of animal and plant residue (including kitchen waste, crop residue, et...

Embodiment 3

[0029] (1) Preparation of composite microbial strains: The mass percentages were 40% of chaff, 40% of wheat bran, and 20% of corn flour, and mixed evenly in proportion. The main ingredients are fully mixed, first aerobic fermentation for 10 days, then anaerobic continuous fermentation for 10 days, low-temperature drying, moisture content ≤ 12%, bagged and sealed for storage.

[0030] (2) Pre-fermentation: Add the compound microbial strains described in step (1) into the organic fertilizer raw material with an inoculum amount of 1% by mass, mix and evenly pile up to a height of 2 meters, supply oxygen and ferment for 10 days, and turn the pile every day during the period . Organic fertilizer raw materials and their corresponding mass percentages are: 25% weeds, 14% livestock manure, 28% animal and plant residues (including kitchen waste, crop residues, etc.), 10% peanut bran, 15% pond mud, urea 1%, superphosphate 3.5%, magnesium sulfate 0.5%, slaked lime 2.5%, zeolite powder 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com