A single-side broaching gear broach with the same profile

A unilateral, gear technology, applied in gear tooth manufacturing tools, gear tooth manufacturing devices, belts/chains/gears, etc., can solve problems such as poor chip removal, achieve stable broaching, small deformation of parts, and improve processing roughness The effect of speed and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

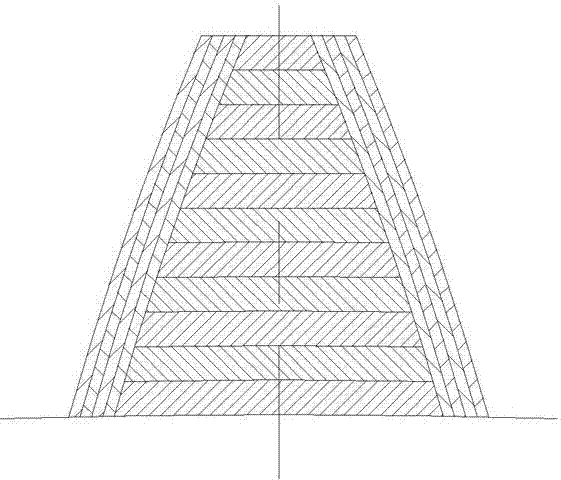

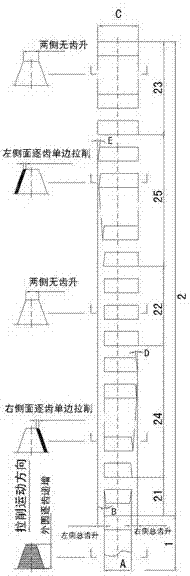

[0013] like image 3 As shown, the same-profile single-side broaching gear broach of the present invention is composed of two segments of teeth, including a front segment 1 and a rear segment 2 . The front section 1 is a rough broach tooth section with a progressive forming structure, and the rear section 2 is a fine broach tooth section with a contour forming structure, and its broaching is no different from that of a common structure broach. The cutter teeth of the rear segment 2 are broached with single-side tooth lift. The first tooth (first tooth) 21 of the rear section 2 is symmetrical to the center of the front section 1, and the tooth width dimension A of the two is the same. Enter back section 2. A number of transition teeth 22 are designed in the middle of the rear section 2 . Both sides of the transition tooth 22 have no tooth rise and relief angle, and the tooth width dimension is an inverted cone within the tolerance range. The number of teeth of the transition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com