A method for continuously extracting active ingredients in seabuckthorn seeds

A technology of active ingredients and seabuckthorn seeds, which is applied in the field of extraction and separation and purification of natural products, can solve the problems of incomplete extraction and low extraction efficiency, achieve low extraction cost, short extraction time, and prevent waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

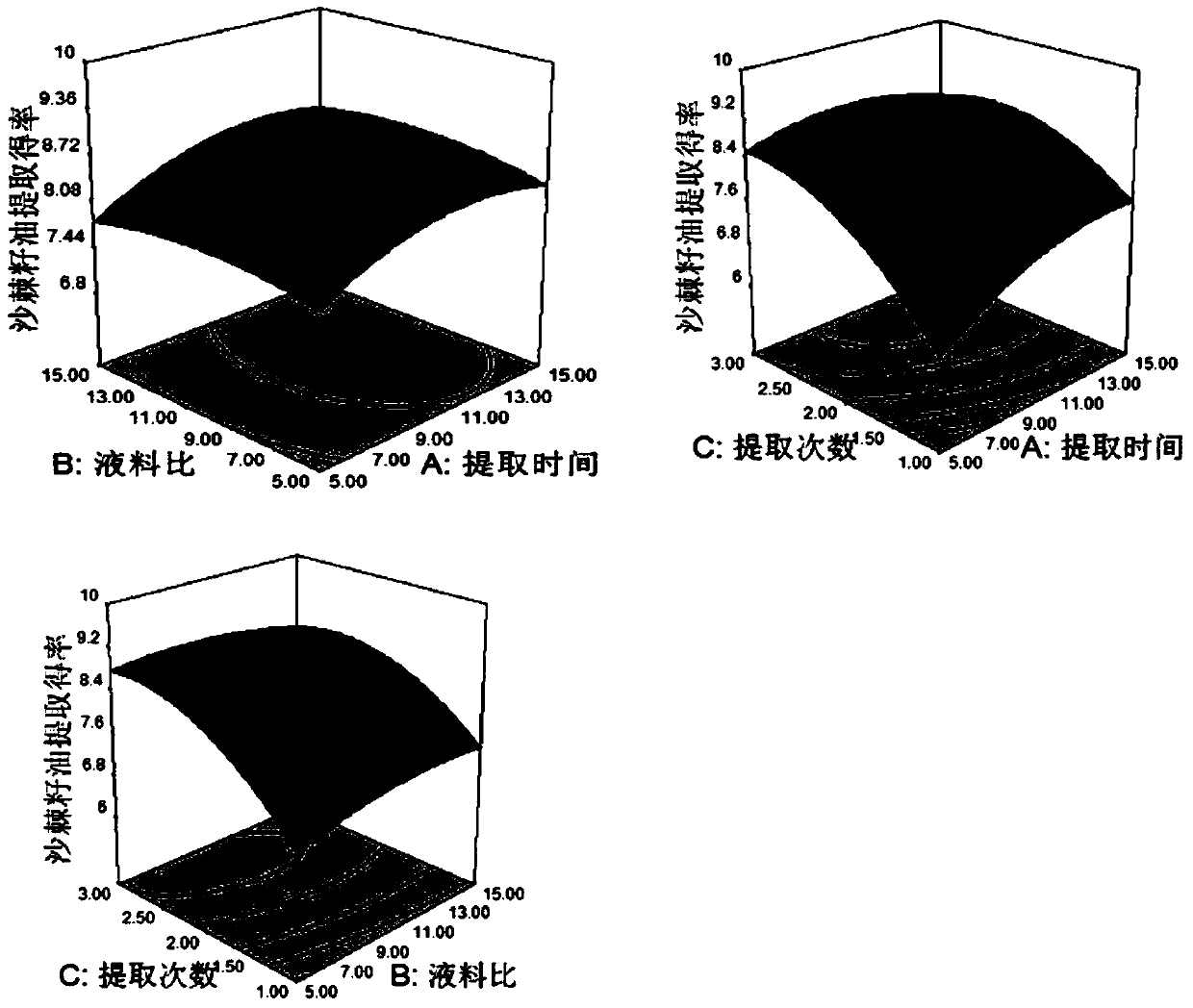

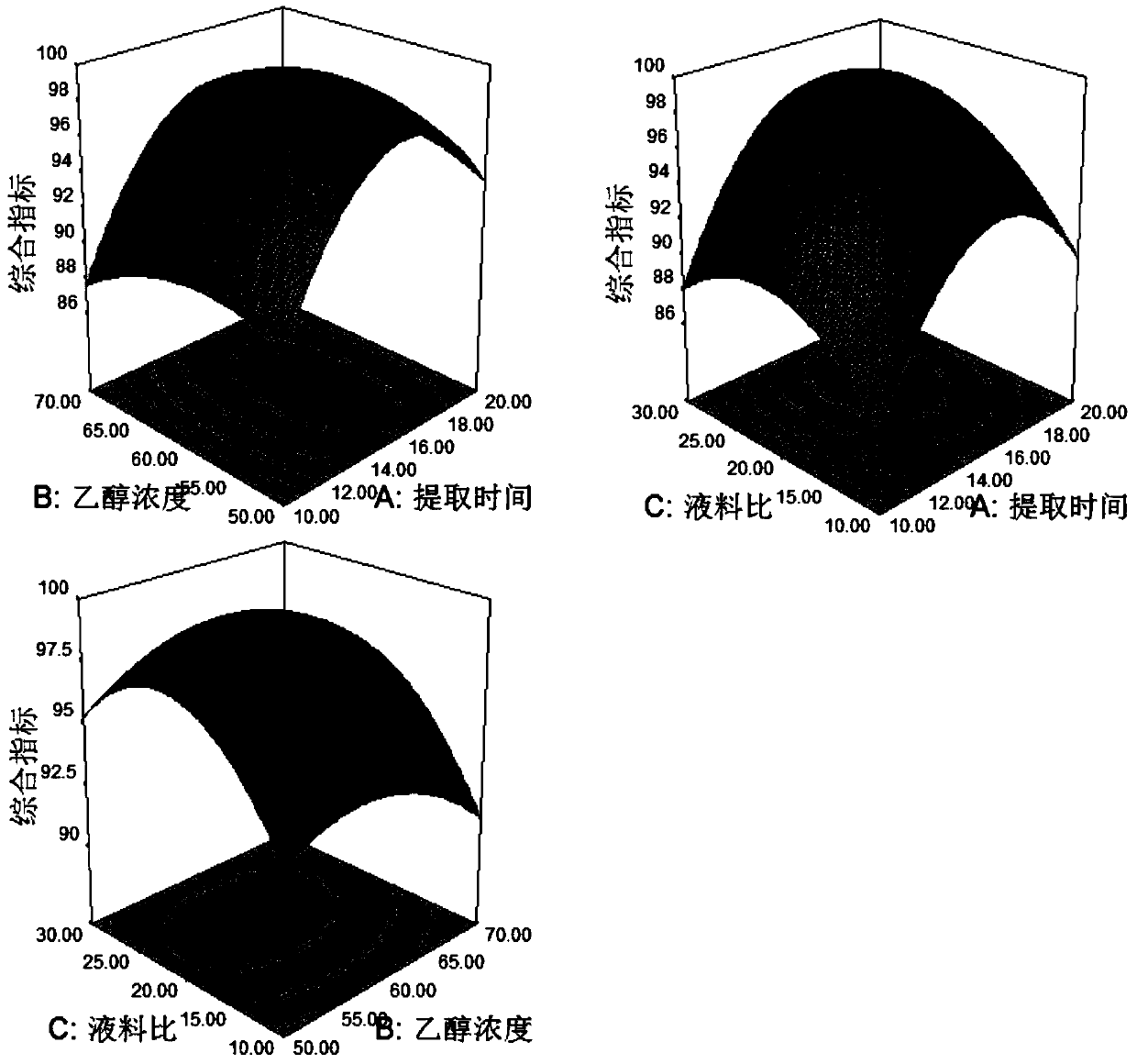

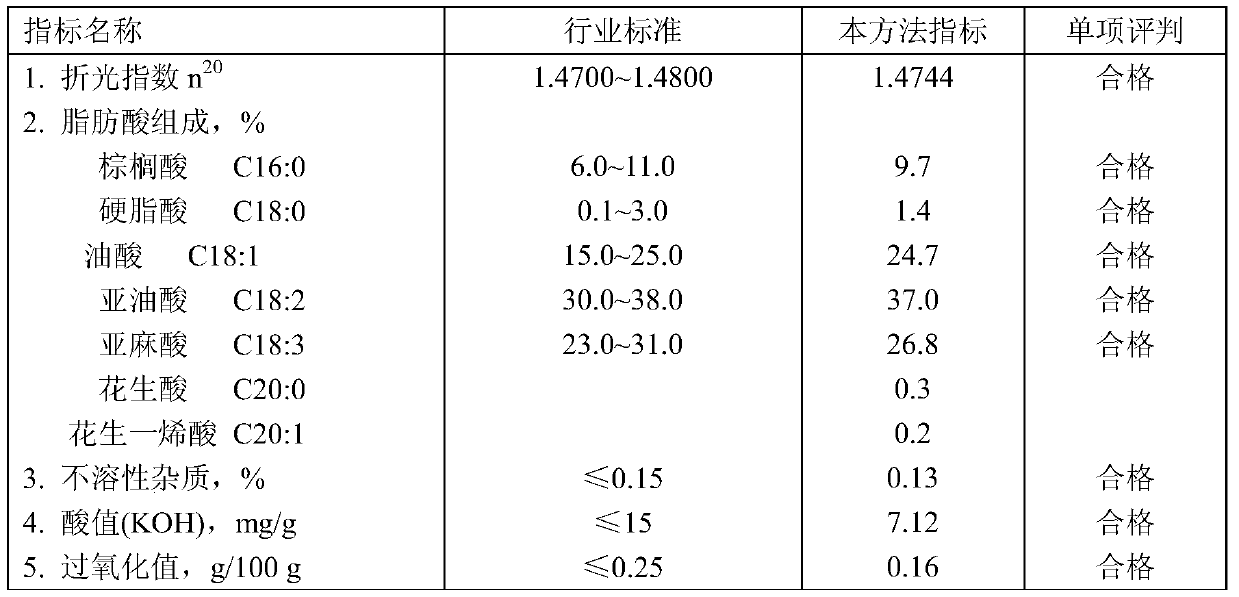

Method used

Image

Examples

Embodiment 1

[0062] Crush the clean and dry seabuckthorn seeds, put them in a sealable container, add n-hexane with a volume-to-weight ratio of 10 times, and extract ultrasonically for 5 minutes at a frequency of 30kHz, a power of 400W, and a temperature of 20°C. obtaining seabuckthorn seed oil extract; filtering the extract, recovering the solvent under reduced pressure (controlling the temperature not to exceed 30°C), and removing residual solvent to obtain seabuckthorn seed oil;

[0063] Add 50% ethanol-water solution with a volume-to-weight ratio of 10 times to the oil meal after extracting sea-buckthorn seed oil, and the power is 400W and the frequency is 30kH Z , ultrasonic extraction for 40 minutes at a temperature of 20° C. to obtain crude extracts of total flavonoids and total triterpene saponins from seabuckthorn seeds; filter the crude extracts under reduced pressure, concentrate under reduced pressure at 30° C., and place the concentrate in Vacuum and low-temperature drying at ...

Embodiment 2

[0067] Crush the clean and dry seabuckthorn seeds, put them in a sealable container, add petroleum ether with a volume-to-weight ratio of 20 times, and perform ultrasonic extraction for 30 minutes at a frequency of 80kHz, a power of 3000W, and a temperature of 30°C. Obtaining the seabuckthorn seed oil extract; filtering the extract, recovering the solvent under reduced pressure, and removing residual solvent to obtain the seabuckthorn seed oil; adding an 80% ethanol-water solution with a volume-weight ratio of 30 times to the oil meal after extracting the seabuckthorn seed oil, At a power of 3000W and a frequency of 80kH Z , Ultrasonic extraction at a temperature of 50°C for 10 minutes to obtain crude extracts of total flavonoids and total triterpene saponins from seabuckthorn seeds; filter the crude extracts under reduced pressure, concentrate under reduced pressure at 40°C, and concentrate under reduced pressure at 40°C Vacuum and low-temperature drying to obtain a crude ext...

Embodiment 3

[0071] The clean and dry seabuckthorn seeds are crushed and peeled, loaded in a sealable container, added with n-hexane with a volume-to-weight ratio of 30 times, and ultrasonically extracted at a frequency of 40kHz, a power of 800W, and a temperature of 30°C for 15 minutes. Obtain the seabuckthorn seed oil extract; filter the extract, recover the solvent under reduced pressure (control the temperature not to exceed 30°C), and remove the residual solvent to obtain the seabuckthorn seed oil; add a volume-to-weight ratio of 15 times 60% ethanol-water solution, at a power of 800W and a frequency of 40kH Z , ultrasonic extraction for 20 minutes at a temperature of 40°C to obtain crude extracts of total flavonoids and total triterpene saponins from seabuckthorn seeds; filter the crude extracts under reduced pressure, concentrate under reduced pressure at 30°C, and dilute the concentrate in Vacuum and low-temperature drying at 30°C to obtain a crude extract; add cold water with a vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com