Longsnout catfish fillet coating antistaling agent, preparation method and fresh-keeping method thereof

A film-coated preservative and catfish fillet technology, which is applied to the preservation of meat/fish with chemicals and the preservation of meat/fish with protective coatings, etc., can solve the problems of fat oxidation and microbial spoilage, rapid product quality decline, and shelf life. Short and other problems, to achieve the effect of reducing juice loss, simple use method, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

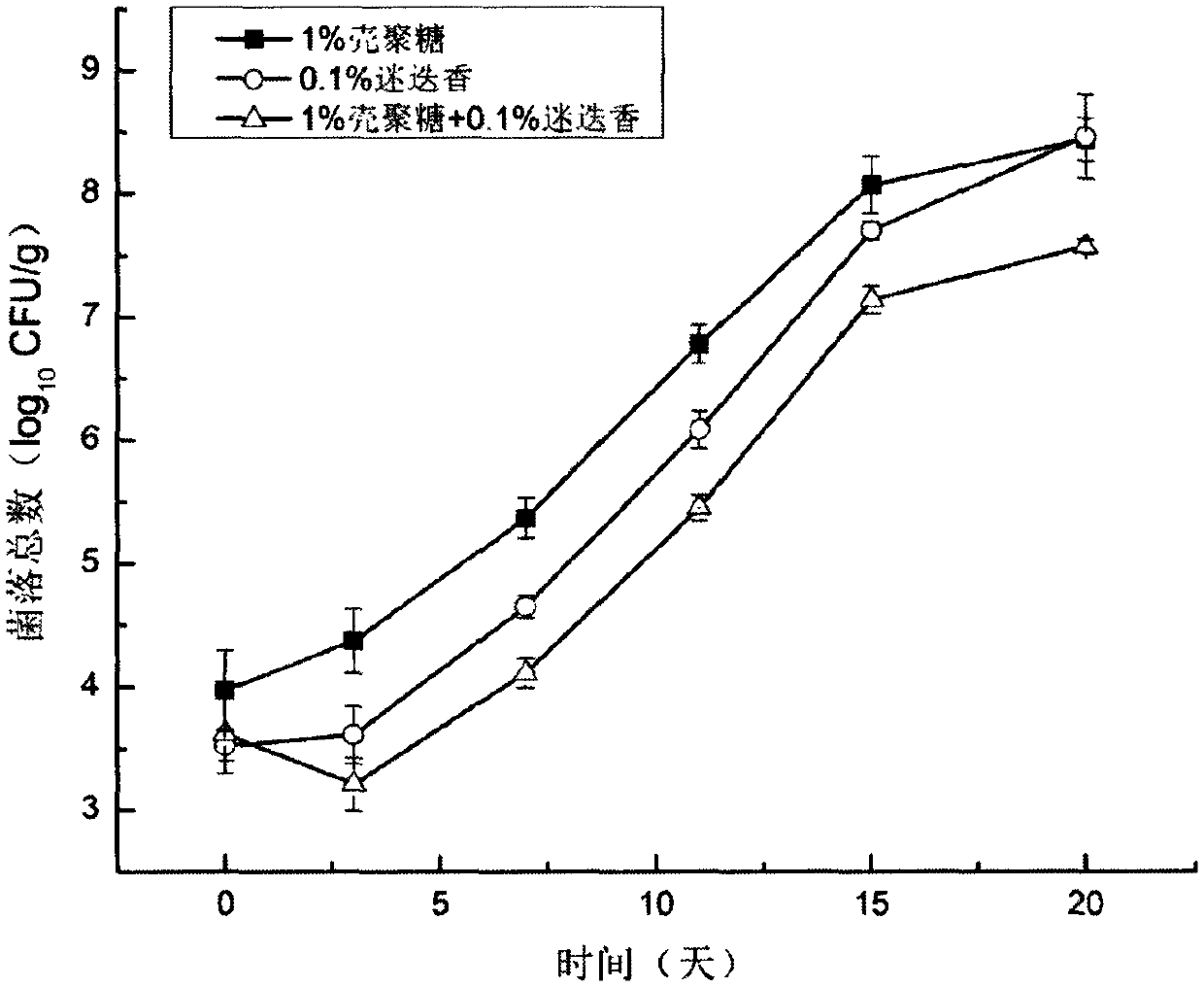

Problems solved by technology

Method used

Image

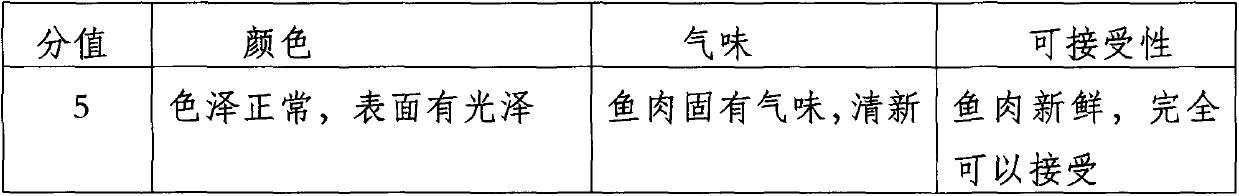

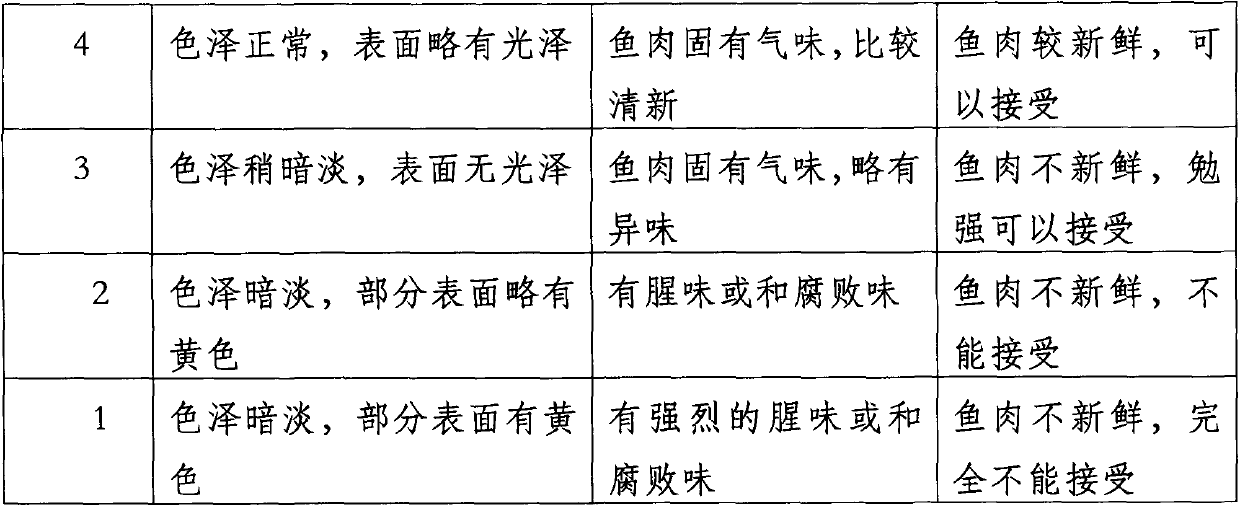

Examples

Embodiment 1

[0020] (1) Preparation of coating preservative: take 5g chitosan (molecular weight: 300,000, degree of deacetylation: 85%), dissolve with 500mL1% acetic acid solution, stir magnetically at room temperature until particles exist, and ultrasonically remove it for 30 minutes. gas, add glycerin and Tween-80 each 1.25g, stir evenly to obtain 1% chitosan coating preservative liquid solution.

[0021] (2) Slaughtering and slicing: Fresh and live catfish were killed in ice water, slaughtered and cleaned, and cut into fish fillets with a thickness of about 1 cm; the processed fish fillets were rinsed in pre-cooled sterile water for 10 seconds, and taken out at 4°C Drain.

[0022] (3) Coating treatment: immerse the drained fish fillets (about 200g) in the pre-cooled coating preservative for 30s.

[0023] (4) Film-forming packaging: take out the fish fillets and place them on a sterile wire mesh, dry them with cold air (about 4°C) and form a film, then put them into a retort bag and sea...

Embodiment 2

[0026] (1) Preparation of film preservative: take 5g chitosan (300,000 molecular weight, 85% degree of deacetylation), dissolve with 400mL1.25% acetic acid solution, stir magnetically at room temperature until particles exist, and ultrasonically 30 Minute degassing, add glycerin and Tween-80 each 1.25g, stir evenly to obtain solution A; weigh 0.5g rosemary extract powder, dissolve with 50mL deionized water to obtain solution B; mix solution A and solution B, Adjust to 500mL with deionized water, mix well and refrigerate for later use.

[0027] (2) Slaughtering and slicing: Fresh and live catfish were killed in ice water, slaughtered and cleaned, and cut into fish fillets with a thickness of about 1 cm; the processed fish fillets were rinsed in pre-cooled sterile water for 10 seconds, and taken out at 4°C Drain.

[0028] (3) Coating treatment: immerse the drained fish fillets (about 200g) in the pre-cooled coating preservative for 30s.

[0029] (4) Film-forming packaging: tak...

Embodiment 3

[0032] (1) Preparation of film preservative: take 10g chitosan (molecular weight: 400,000, degree of deacetylation: 75%), dissolve with 400mL1.25% acetic acid solution, stir magnetically at room temperature until particles exist, and sonicate for 30 Minute degassing, add 2.5g each of glycerin and Tween-80, stir evenly to obtain solution A; weigh 1g of rosemary extract powder, dissolve with 50mL deionized water to obtain solution B; mix solution A and solution B, and use Adjust the deionized water to 500mL, mix well and refrigerate for later use.

[0033] (2) Slaughtering and slicing: Fresh and live catfish were killed in ice water, slaughtered and cleaned, and cut into fish fillets with a thickness of about 1.5 cm; rinsed the fish fillets in pre-cooled sterile water for 15 seconds, took them out and drained them at 4°C Dry.

[0034] (3) Coating treatment: immerse the drained fish fillets (about 400g) in the pre-cooled coating preservative for 45s.

[0035] (4) Film-forming p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com