Copper clad laminate hydraulic pressurization forming device

A technology of pressure molding and copper clad laminates, which is applied in the direction of electrical components, printed circuit manufacturing, printed circuits, etc., can solve the problems of high molding pressure, poor uniformity, and high product warpage, and achieve reduced resin curing and high warpage Small, less prone to white spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0023] After several production tests, the applicant found that only relying on the temperature increase of the liquid medium in the sub-container to increase the pressure is slow, and the production efficiency is low. To determine the state, there is a security risk in production.

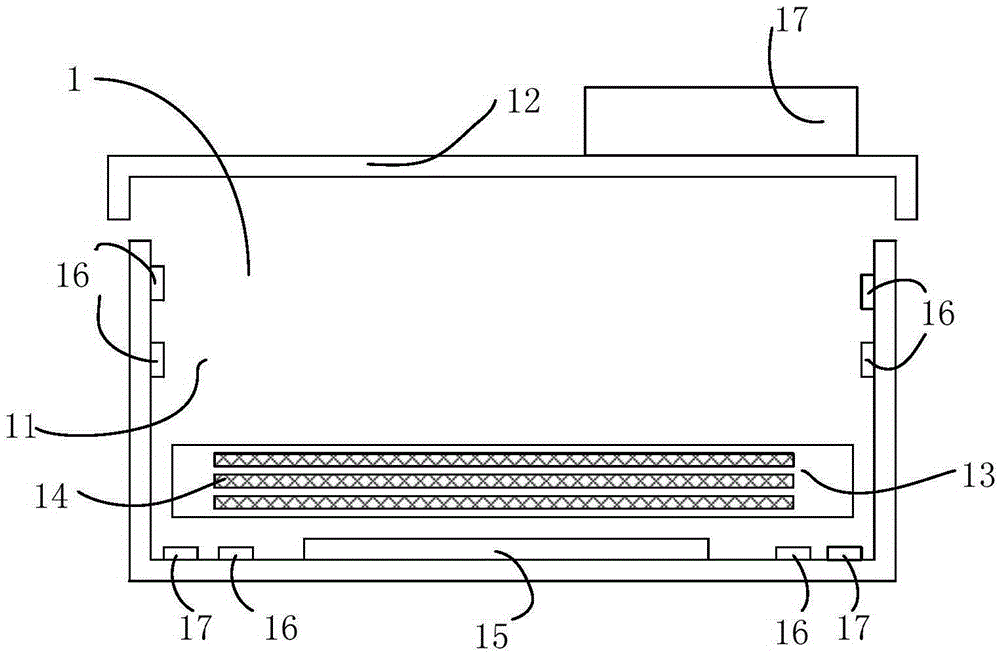

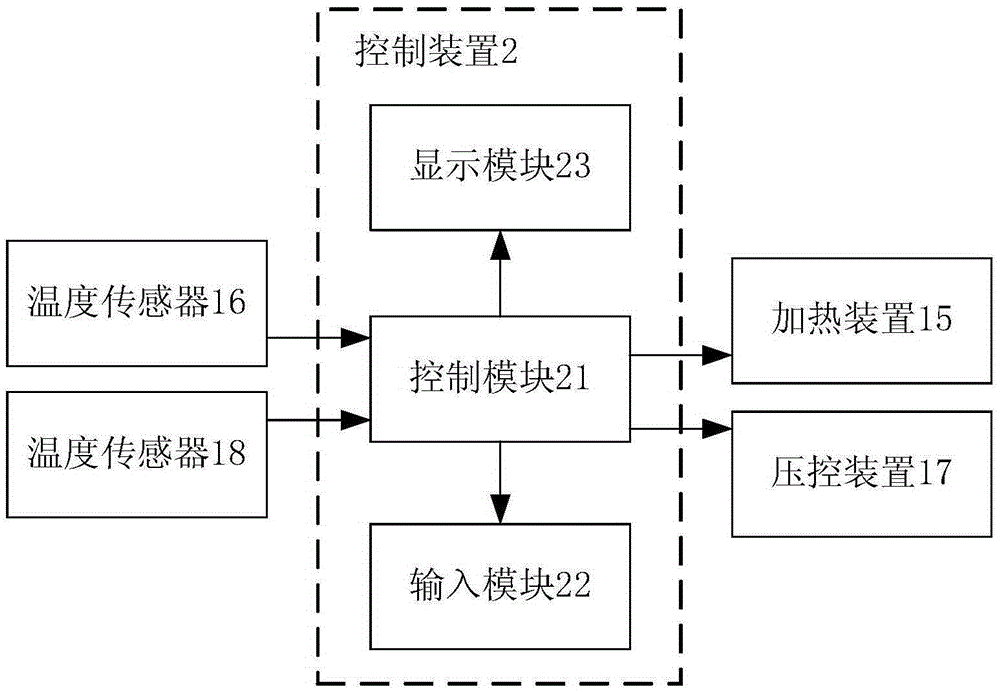

[0024] In order to overcome the shortcomings of the existing technology, please refer to figure 1 and figure 2 , which is a schematic structural view of a copper clad laminate hydraulic pressure forming device provided by an embodiment of the present invention, including a pressing container 1 and a control device arranged on the outer wall of the pressing container for controlling the pressing container to complete the lamination operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com