Filter unit applied to plug-pull type hydraulic system

A technology of hydraulic system and filter device, applied in the direction of fluid pressure actuating device, fluid pressure actuating system components, mechanical equipment, etc., can solve problems such as hydraulic equipment damage, reduce equipment wear, reduce pollution, and improve service life and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

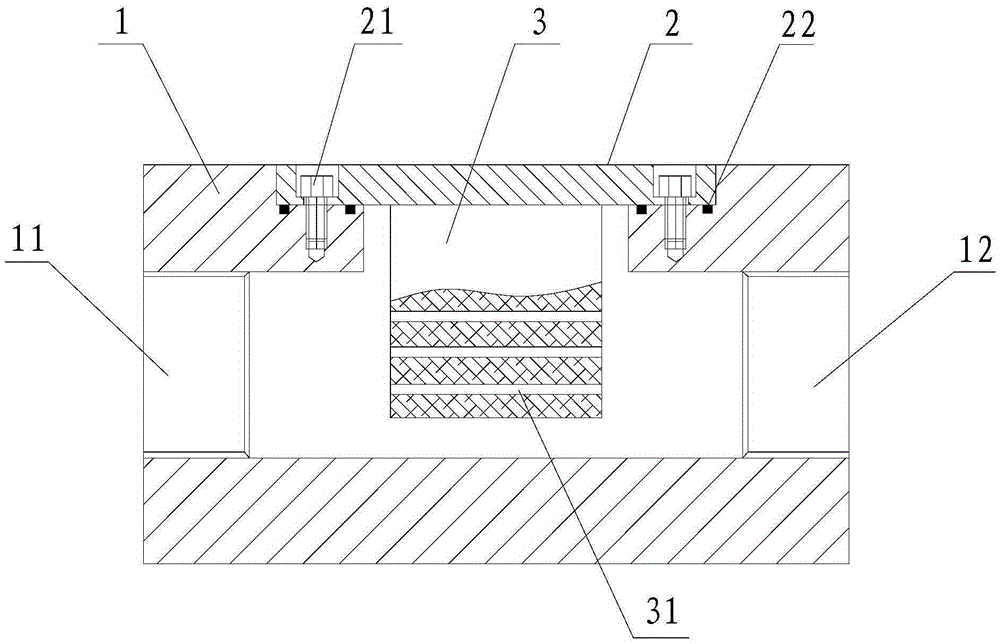

[0016] Such as figure 1 As shown, the present invention includes a housing 1 that is hollow and has an inlet 11 and an outlet 12, that is, the inlet 11 and the outlet 12 communicate with the hollow of the housing 1, and the side wall of the housing 1 has a through hole, and The through hole is equipped with an end cover 2, which is sealed and openable with the housing 1. A magnet 3 is installed on the inner side of the end cover 2. The magnet 3 is preferably located in the middle of the housing 1 to ensure sufficient contact with the hydraulic oil. touch. When in use, the filter device can be installed at the outlet of the terminal oil cylinder or on the pipeline of the hydraulic system. The hydraulic oil enters from the inlet 11 and flows out from the outlet 12. When it flows through the magnet 3, the iron particles in the hydraulic oil will be absorbed by the magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com