Dyeing method of double-faced wool fabric

A dyeing method and double-sided wool technology, applied in the field of textiles, can solve the problems of easy occurrence of felt shrinkage, impermeability of wool and wool, and difficult color penetration, so as to improve the felt shrinkage of the door width, the color is uniform, and the dyeing color can be solved. flower effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

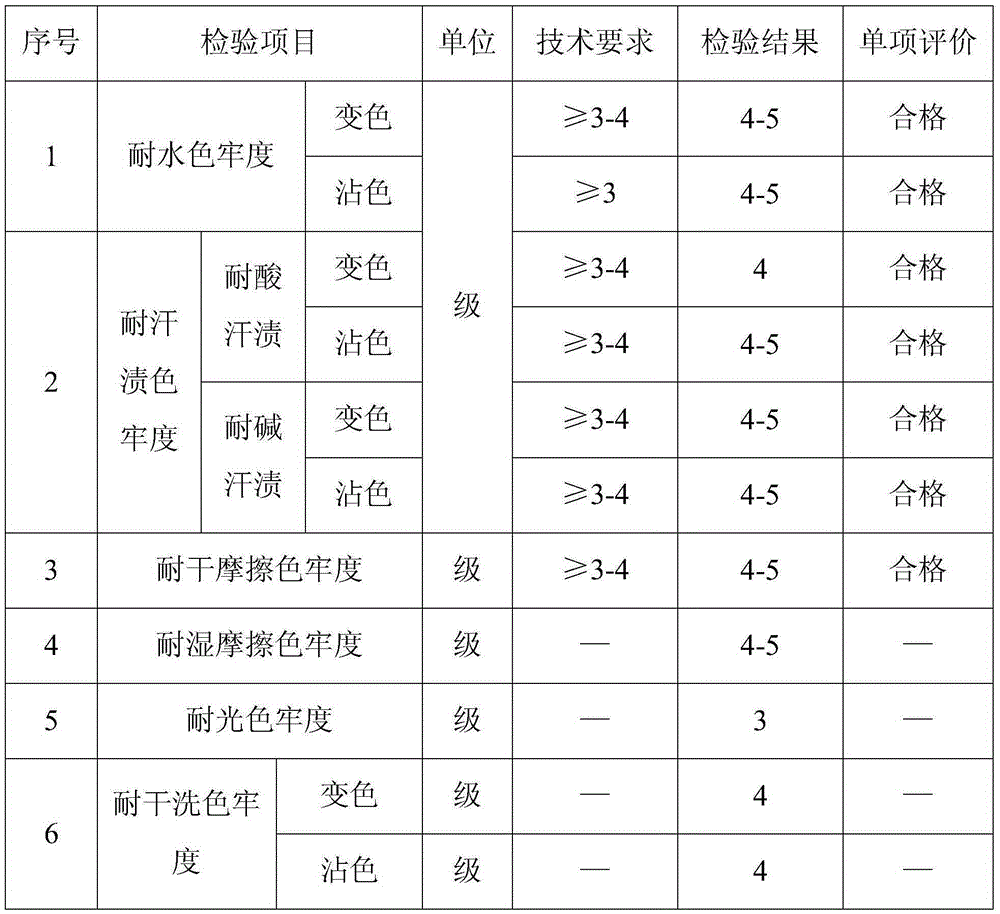

Examples

Embodiment 1

[0015] The method of dyeing double-faced fabrics includes the following steps: hemming of grey cloth → dehydration → shrinking → washing → dyeing → setting and drying → fixed width → steaming → raising;

[0016] The dyeing process includes: pretreatment with penetrant → room temperature cleaning → drying → treatment with a leveling agent accounting for 2.1% of the weight of the grey fabric → treatment with a penetrant accounting for 0.9% of the weight of the grey fabric → glacial acetic acid with pH=5.8 Aqueous solution treatment→treatment with ammonium sulfate accounting for 1.1% of the mass of the grey fabric→treatment with an aqueous sulfuric acid solution, the pH of the aqueous sulfuric acid solution=2.4, and then wash.

[0017] Then add the dye, run for more than 20 minutes, heat up to 60±2°C at a rate of 0.6°C / min, then heat up to 70~75°C for more than 20 minutes, and then heat up to 98±2°C for more than 1 hour; add the The soaping agent of 2.2% of the grey fabric mass is hea...

Embodiment 2

[0021] The method of dyeing double-faced fabrics includes the following steps: hemming of grey cloth → dehydration → shrinking → washing → dyeing → setting and drying → fixed width → steaming → raising;

[0022] The dyeing process includes: pretreatment with penetrant → room temperature cleaning → drying → treatment with a leveling agent accounting for 1.9% of the weight of the grey fabric → treatment with penetrant accounting for 1.1% of the weight of the grey fabric → pH=5.5-6.0 Treatment with glacial acetic acid aqueous solution → treatment with ammonium sulfate accounting for 0.9% of the mass of the grey cloth → treatment with aqueous sulfuric acid solution, pH of the aqueous sulfuric acid solution = 2.3 ~ 2.5, and then wash;

[0023] Dyeing method of double-faced fabrics When dyeing light colors, add sodium sulfate which accounts for 5.2% of the weight of the grey fabric and run for more than 15 minutes, then add dye, run for more than 20 minutes, and heat up to 60± at a rate o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com