Method for efficiently preparing low-molecular-weight fish skin collagen peptide through enzyme method

A fish skin collagen and low molecular weight technology is applied in the field of enzymatically efficient preparation of low molecular weight fish skin collagen peptides. Absorbability and other issues, to achieve high water solubility and digestion and absorption, good environmental and social benefits, and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: A small-scale preparation method of fish skin collagen peptide, the steps are as follows:

[0042] (i) After activating the deep-sea bacteria Pseudoalteromonas sp.SM9913 on the plate for three consecutive times, pick a single colony to inoculate the liquid seed medium, shake culture at 15-20℃ for 24h, and then press 1% (v / v) inoculum Inoculate the fermentation medium, cultivate at 15°C for 72-84h, 4°C, 12000rpm centrifugation to prepare MCP-01 crude enzyme solution, and store at 4°C at low temperature. The components of the solid medium are as follows, all in parts by weight:

[0043] 0.8-1.0 parts of peptone, 0.5-0.75 parts of yeast powder, 1.0-1.5 parts of agar, 100 parts of artificial sea water, pH 7.5-8.0;

[0044] The components of the liquid seed medium are as follows, all by weight:

[0045] 0.8-1.0 parts of peptone, 0.5-0.75 parts of yeast powder, 100 parts of artificial sea water, pH 7.5-8.0;

[0046] The components of the fermentation medium are as follows,...

Embodiment 2

[0054] An enzymatic method for efficiently preparing low molecular weight fish skin collagen peptides includes the following steps:

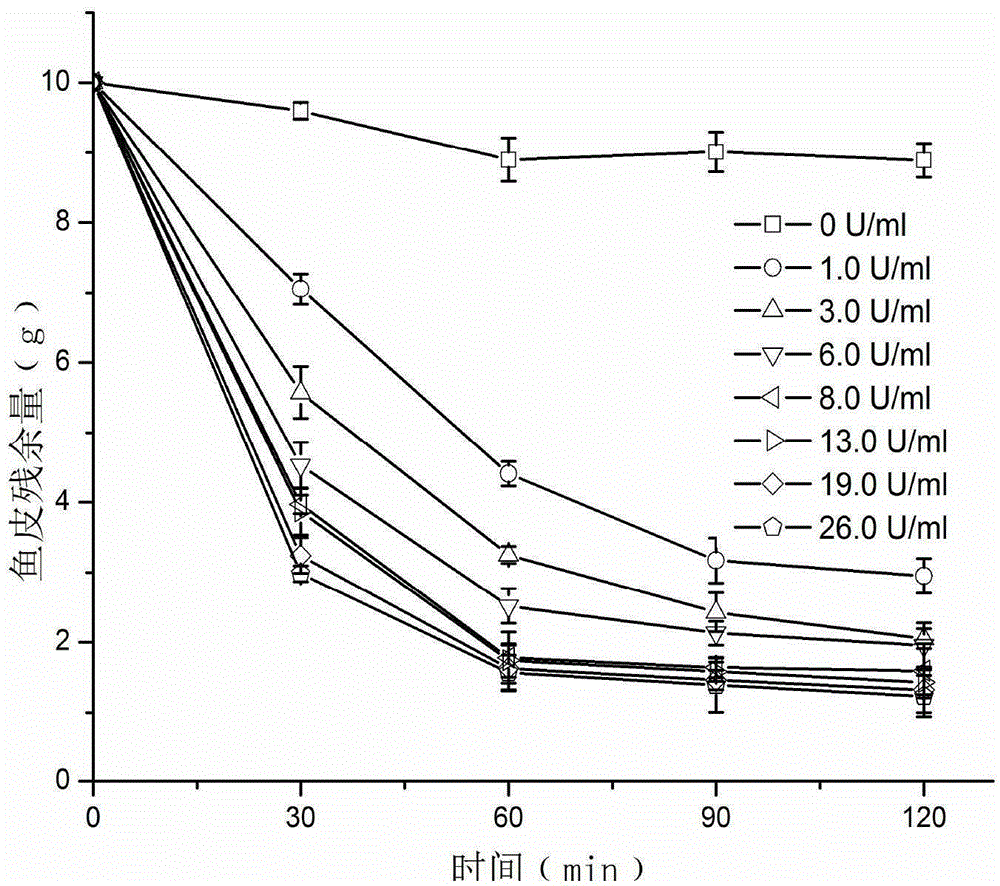

[0055] (1) After breaking the pretreated fish skin, add MCP-01 enzyme solution in an amount of 1 U / g. The ratio of the broken fish skin to the volume of the reaction system in the reaction system is 0.5:1, unit g / mL, at 37°C, 150 rpm, and pH 7, after enzymatic hydrolysis for 2 hours, the reaction solution was prepared;

[0056] The pretreated fish skin is the fish skin after fat removal and ash removal. The fat removal steps are as follows:

[0057] After the fish skin is rinsed with water, it is soaked in a NaOH solution with a concentration of 0.08M for 14 hours, washed with water until it is neutral, and the fatty fish skin is obtained;

[0058] The steps to remove ash are as follows:

[0059] Immerse the fat-removed fish skin in hydrochloric acid with a concentration of 0.25M for 5 hours, wash with water until it is neutral, and obtain the ash-remov...

Embodiment 3

[0071] An enzymatic method for efficiently preparing low molecular weight fish skin collagen peptides includes the following steps:

[0072] (1) After breaking the pretreated fish skin, add MCP-01 enzyme solution in an amount of 30 U / g. The ratio of the broken fish skin to the volume of the reaction system in the reaction system is 1:1, unit g / mL, under the conditions of 40℃, 170rpm, pH 7.5, after enzymatic hydrolysis 0.5, the reaction solution is prepared;

[0073] The pretreated fish skin is the fish skin after the fat and ash have been removed. The fat removal steps are as follows:

[0074] After the fish skin is rinsed with water, it is soaked in NaOH solution with a concentration of 0.12M for 10 hours, and the water is washed until it is neutral to obtain a fatty fish skin;

[0075] The steps to remove ash are as follows:

[0076] Immerse the fat-removed fish skin in hydrochloric acid with a concentration of 0.35M for 3 hours, and wash the paper to be neutral to obtain ash-remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com