Preparation method for m-chlorophenol source hyper-fluorescent carbon dots

A technology for carbon quantum dots and m-chlorophenol, which is applied in the field of solvothermal preparation of fluorescent carbon dots, can solve the problems of high cost, long time for photocatalytic degradation of m-chlorophenol, incomplete mineralization, etc. The effect of promoting value and conditions that are easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 0.2g of m-chlorophenol, disperse in 20mL of methanol and water mixed solvent with a volume ratio of 3:7, and disperse evenly under stirring or ultrasonic conditions; In the reaction axe, nitrogen was passed to remove dissolved oxygen for 1 hour; heated in an oven at 170°C for 10 hours and then naturally cooled to room temperature, the reaction solution in the liner was taken out and centrifuged at 10,000 rpm for 10 minutes to remove large particles; The unreacted precursor was extracted three times with methane to obtain purified highly fluorescent carbon quantum dots.

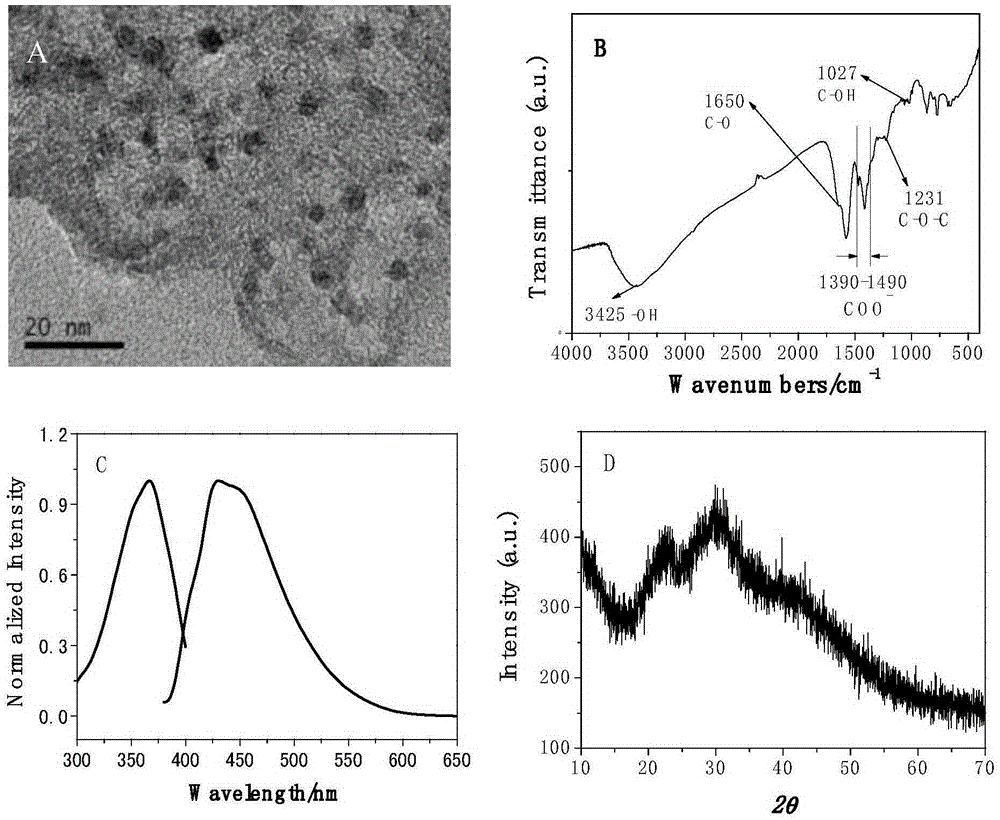

[0022] figure 1 It is a characterization diagram of carbon quantum dots obtained in Example 1. figure 1 A is the transmission electron microscope image of carbon quantum dots, which shows that carbon quantum dots are spherical uniform monodisperse particles with uniform size distribution. figure 1 B is the infrared spectrum of carbon quantum dots. It can be seen from the figure that there are a ...

Embodiment 2

[0025] Weigh 0.3g of m-chlorophenol, disperse in 20mL of mixed solvent of methanol and water with a volume ratio of 1:1, and disperse evenly under stirring or ultrasonic conditions; transfer the solution to a 30mL polytetrafluoroethylene liner In the high-pressure reaction axe, nitrogen was passed to remove dissolved oxygen for 1 hour; heated in an oven at 190°C for 12 hours and cooled to room temperature naturally, the reaction solution in the liner was taken out, and centrifuged at 10,000 rpm for 10 minutes to remove large particles; finally, 2 times the volume of Dichloromethane extracted the unreacted precursor 4 times to obtain purified highly fluorescent carbon quantum dots.

Embodiment 3

[0027] Weigh 0.1g of m-chlorophenol, disperse in 20mL of mixed solvent of methanol and water with a volume ratio of 1:2, and disperse evenly under stirring or ultrasonic conditions; In the reaction axe, remove dissolved oxygen by blowing nitrogen for 1 hour; heat in an oven at 180°C for 11 hours; cool naturally to room temperature, take out the reaction liquid in the liner, and centrifuge at 10,000 rpm for 10 minutes to remove large particles; use 2 times the volume of dichloro Methane extracted the unreacted precursor twice to obtain purified highly fluorescent quantum carbon dots.

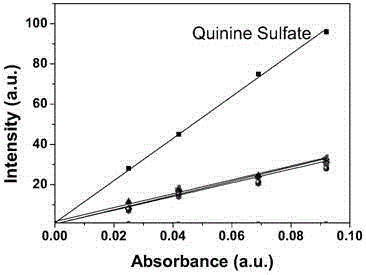

[0028] figure 2 For the quantum yield figure of the carbon quantum dots obtained in Examples 1, 2 and 3, taking quinoline sulfate as a standard, the quantum yields of the three carbon quantum dots are very close, as ~ 17%, indicating that the prepared carbon quantum dots have a higher quantum yield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com