Foamed asphalt cold-recycling lime-fly-ash crush stone mixture and preparation method thereof

A technology of foamed asphalt and limestone crushed stone, which is applied in the field of cold recycled mixture and its preparation, can solve the problems of reflection cracks, frequent occurrence of road surface diseases, inconvenient construction, etc., and achieves the effects of reducing emissions, reducing disease occurrence and protecting cultivated land.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

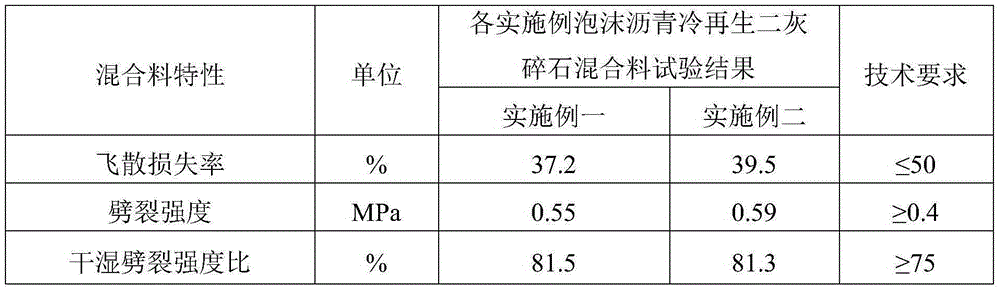

Examples

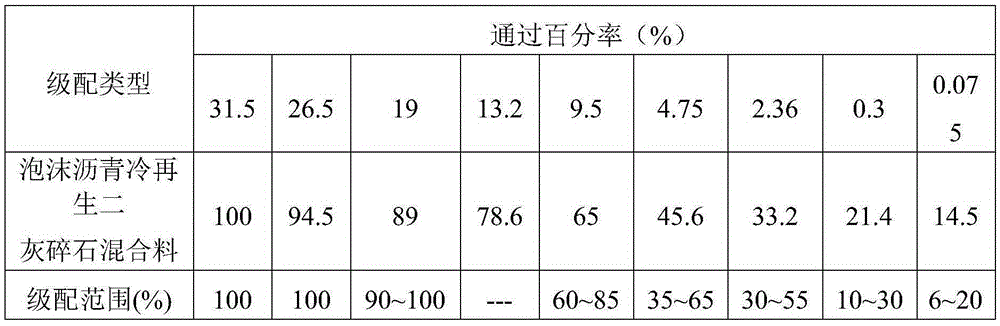

Embodiment 1

[0023] Composition of foamed asphalt cold recycled lime-ash gravel mixture (parts by weight):

[0024] 1. Recycled old materials: 880 copies of RAP material (milling material for the lime-ash gravel base layer at the crack of the old road surface);

[0025] 2. Newly added materials: 100 parts of aggregate (particle size 9.5~13.2mm), 25 parts of foamed asphalt (Jinling Petrochemical No. 70 road petroleum asphalt), of which 0.625 parts of foamed asphalt foaming water consumption and 20 parts of ordinary Portland cement Parts, 31 parts of water (the amount of water added is determined according to the moisture content of the milling material);

[0026] Preparation process steps:

[0027] Step 1: Add the dispersed RAP material to the aggregate and mix evenly at room temperature, then add ordinary Portland cement, mix for 30s, and add potable water in proportion to mix for 30s;

[0028] Step 2: Use special asphalt foaming equipment to foam 70# matrix asphalt at a temperature of 160°C and a ...

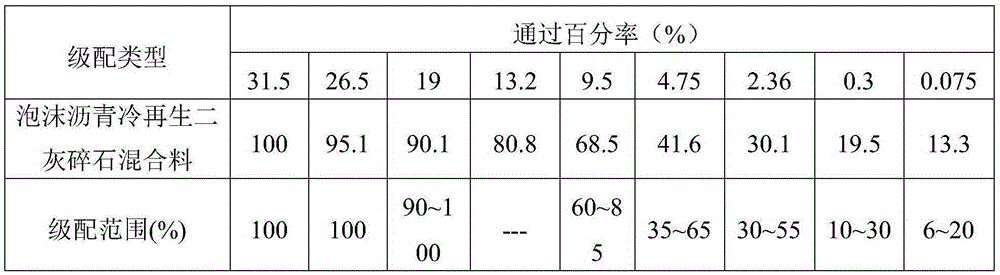

Embodiment 2

[0034] Composition of foamed asphalt cold recycled lime-ash gravel mixture (parts by weight):

[0035] 1. Recycled old materials: 980 copies of RAP material (milling material for lime-ash gravel base layer at the cracks of the old road surface);

[0036] 2. Newly added materials: 25 parts of foamed asphalt (Jinling Petrochemical No. 70 road petroleum asphalt), including 0.625 parts of foamed asphalt foaming water, 20 parts of ordinary Portland cement, 31 parts of potable water (according to the water content of milling materials Rate determines the amount of water added);

[0037] Preparation process steps:

[0038] Step 1: Add the dispersed RAP material to ordinary Portland cement, mix for 40s, and add potable water in proportion to mix for 30s;

[0039] Step 2: Use special asphalt foaming equipment to foam 70# matrix asphalt at a temperature of 150°C and a water consumption of 2.5%;

[0040] Step 3: Add the prepared foamed asphalt to the mixed material mixed in step 1, and fully stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com