Calcium magnesium carbonate salt mine decomposition method

A calcium-magnesium carbonate, decomposition reaction technology, applied in the direction of lime production, etc., can solve the problems of reaction system energy consumption reduction, increase production cost, waste, etc., to reduce heat energy loss, ensure stable production, and reduce energy consumption costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

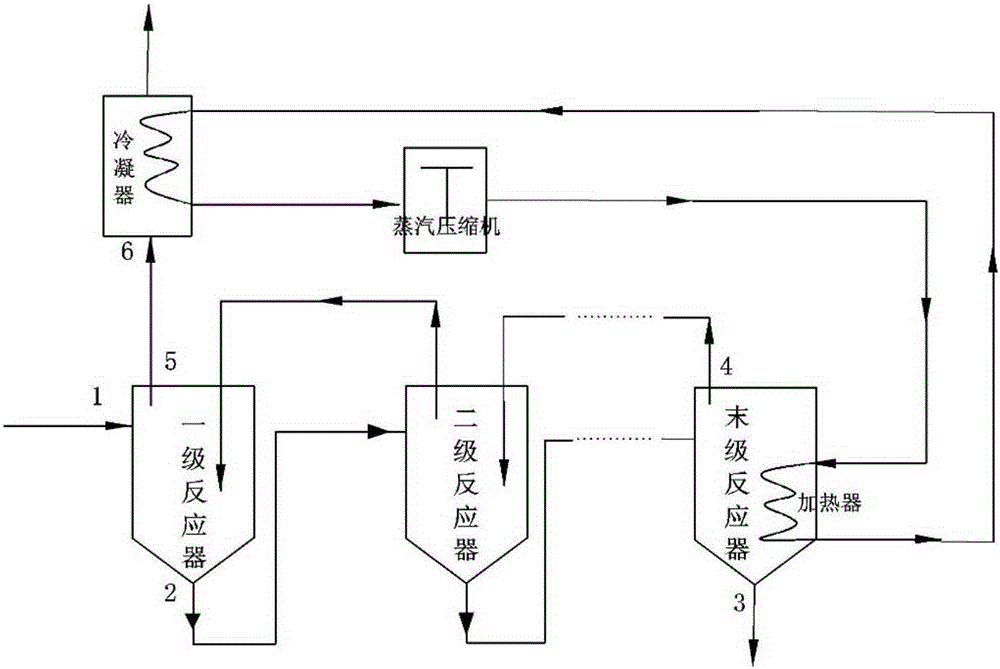

[0067] A kind of decomposition method of calcium magnesium carbonate ore is carried out in the multistage reactor connected in series, comprises the steps:

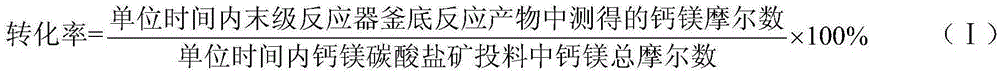

[0068] (1) get the limestone powder that particle diameter is 10-100 μ m and concentration is the ammonium chloride aqueous solution of 10wt% to form slurry after mixing, wherein, control the mol ratio of ammonium ion in the ammonium chloride aqueous solution and the calcium magnesium ion in the limestone powder for NH 4 + : (Ca+Mg)=2:1. The slurry enters the first-stage reactor through the feed port of the first-stage reactor for reaction, is discharged from the outlet of the reaction liquid at the bottom of the first-stage reactor, and then enters the next-stage reactor through the feed port of the next-stage reactor to continue the reaction , after successively reacting through 6 stages of series reactors, the calcium chloride solution and insoluble matter are taken out from the outlet of the reaction liquid at the b...

Embodiment 2

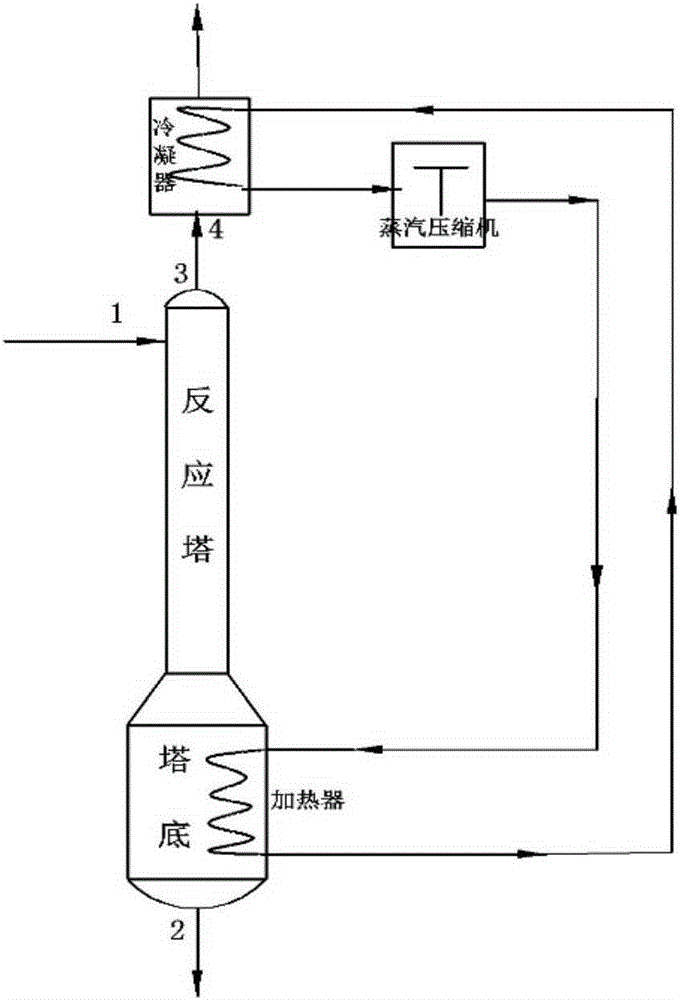

[0075] A method for decomposing calcium-magnesium carbonate ore is carried out in a tower reactor, comprising the steps of:

[0076] (1) Fill the reaction tower with limestone with a particle size of 1-5mm, and the filling height is 5m, so that the limestone can be used not only as a raw material for the reaction, but also as a filler for the reaction tower.

[0077] (2) the ammonium nitrate aqueous solution that concentration is 10wt% is passed into from the tower top ammonium salt solution feeding port of reaction tower, is evenly sprayed on limestone and reacts, and the calcium nitrate solution is taken out from the reaction solution outlet at the bottom of the tower, It is used as a raw material for the preparation of calcium compounds for subsequent production. Simultaneously, by adjusting the flow rate of the ammonium nitrate aqueous solution, the conversion rate of the ammonium nitrate aqueous solution is controlled to 70%. The conversion rate of the ammonium nitrate a...

Embodiment 3

[0084] A kind of decomposition method of calcium magnesium carbonate ore is carried out in the multistage reactor connected in series, comprises the steps:

[0085] (1) Take the magnesite powder with a particle size of 0.1~1mm and mix it with the ammonium sulfate aqueous solution with a concentration of 20wt% to form a slurry, wherein the molar ratio of the ammonium root in the ammonium sulfate aqueous solution to the calcium and magnesium ions in the magnesite powder NH 4 + : (Ca+Mg)=3:1. The slurry enters the primary reactor through the feed port of the primary reactor for reaction, is discharged from the outlet of the reaction liquid at the bottom of the primary reactor, and then enters the secondary reactor through the feed port of the secondary reactor to continue the reaction. The reaction product magnesium sulfate solution and insoluble matter are extracted from the outlet of the reaction liquid at the bottom of the secondary reactor. After solid-liquid separation, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com